A structure-improved cloth cutting workbench

A workbench and channel technology, applied in the field of clothing machinery, can solve problems such as easy to lose scales, and achieve the effect of convenient movement and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

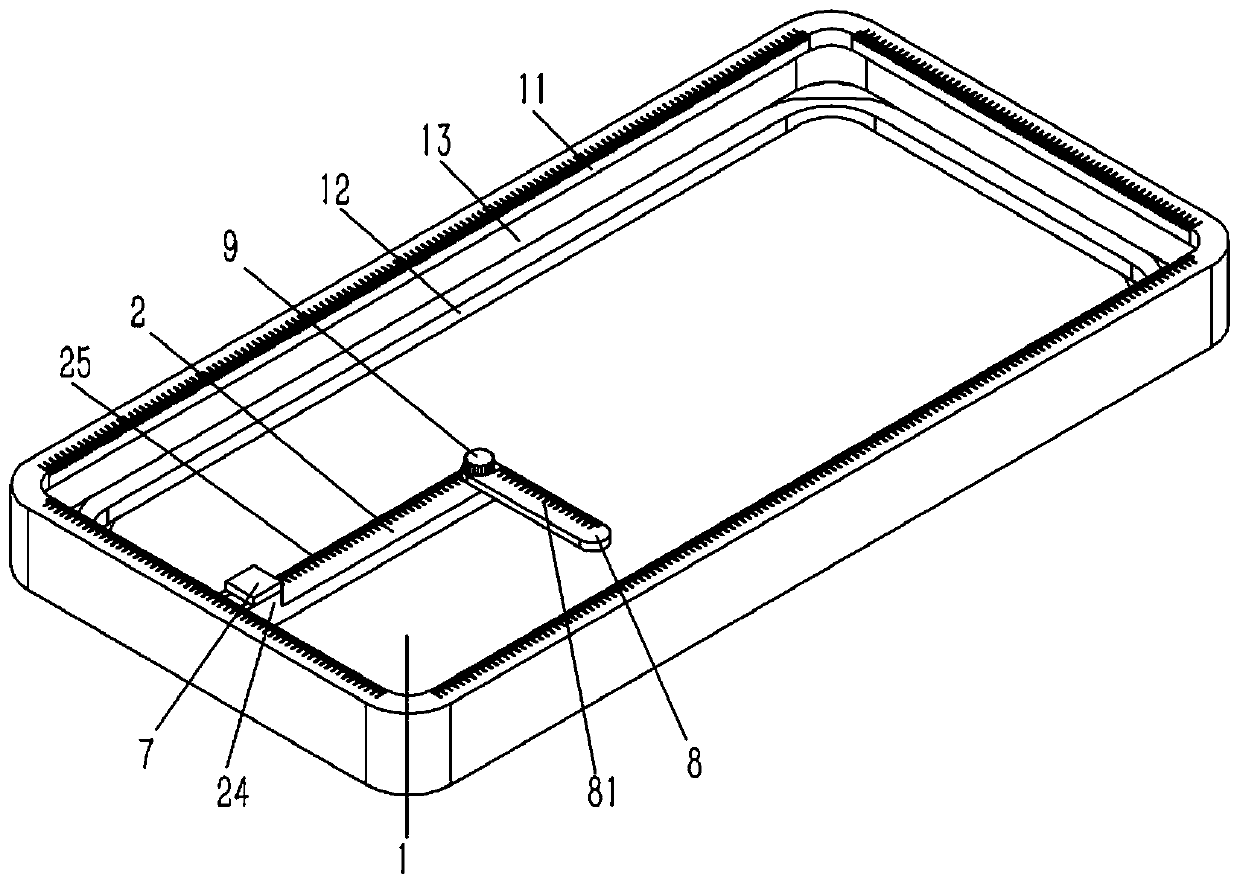

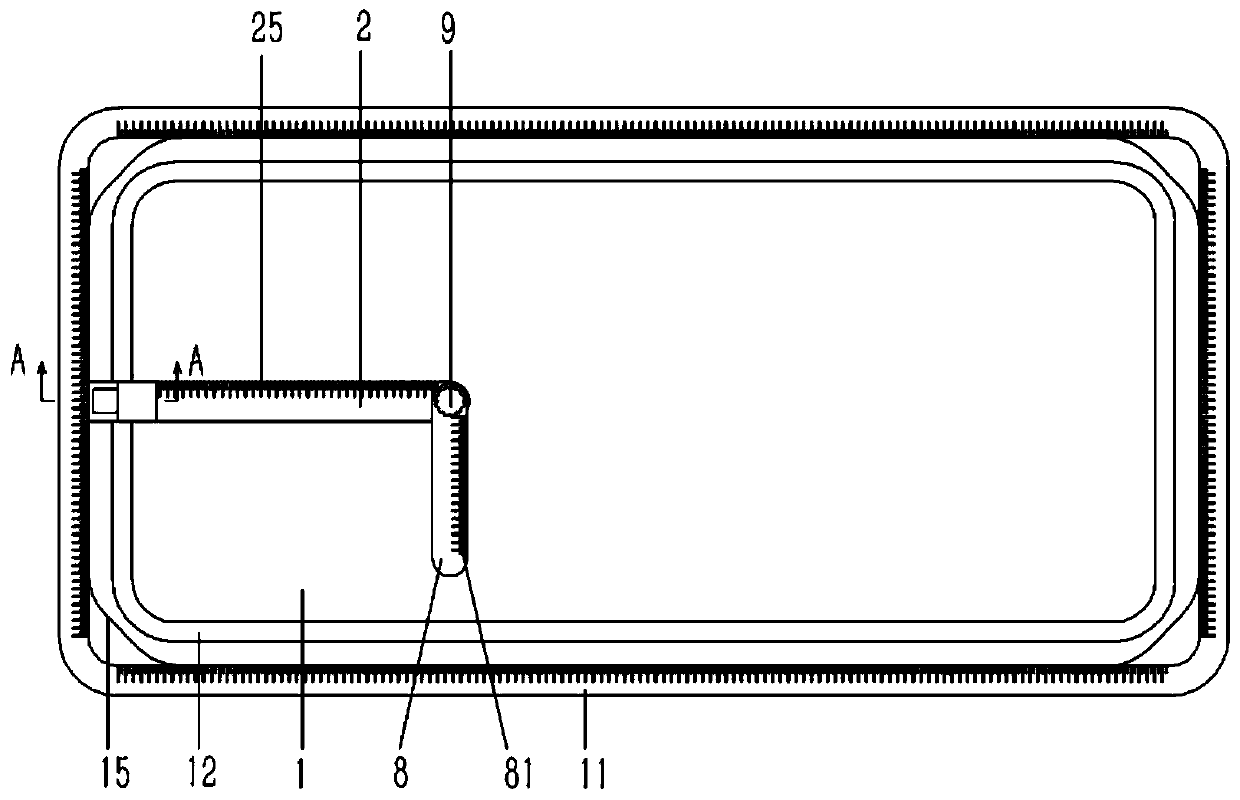

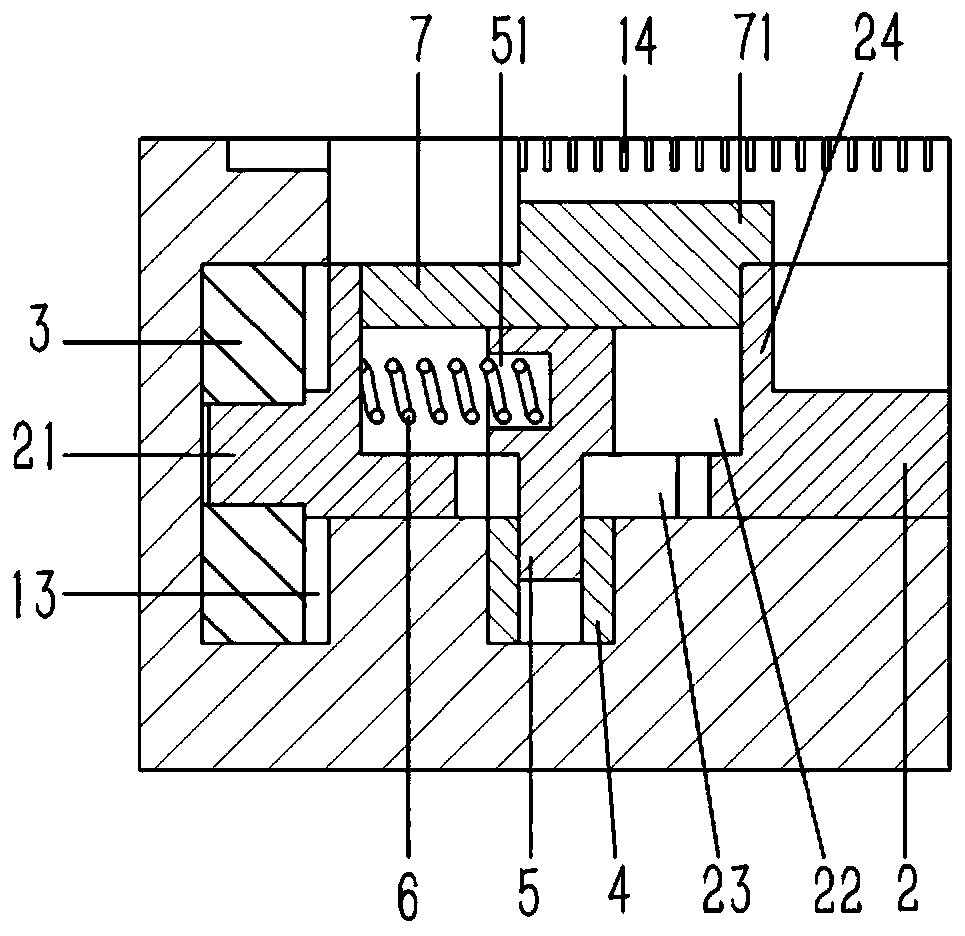

[0018] Example: see Figures 1 to 3 As shown, a cloth cutting workbench with improved structure includes a rectangular workbench 1, a frame 11 is formed around the workbench 1, and an annular outer channel 13 extending downward is formed on the inner side wall of the frame 11. The frame 11. An annular inner channel 12 is formed on the side of the workbench 1 on the inner side; a horizontal main scale 2 is provided on the upper end surface of the workbench 1, and one end of the main scale 2 near the frame 11 of the workbench 1 is formed with The supporting shaft 21, the supporting shaft 21 is inserted into the first roller 3, the first roller 3 is inserted into the outer channel 13 on the frame 11, the outer wall of the first roller 3 is against the upper and lower bottom surfaces of the outer channel 13 Above; the upper end surface of the main scale 2 close to the first roller 3 is formed with a strip-shaped groove 22, and the bottom surface of the groove 22 is formed with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com