A robot out-of-sequence workpiece grasping method based on deep inverse reinforcement learning

A reinforcement learning and robotics technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of low efficiency, hidden dangers, long cycle, etc., to achieve the effect of low efficiency, meet the needs of industrial production, and long cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with drawings and embodiments.

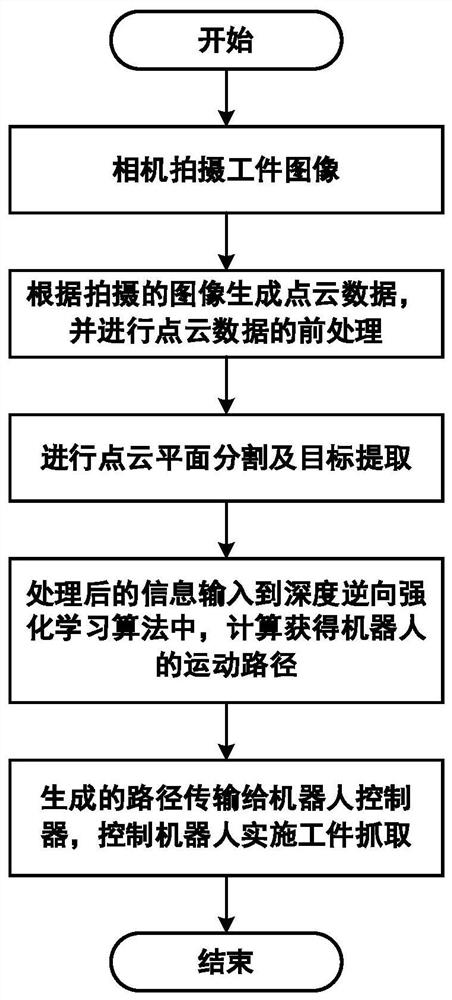

[0042] as attached figure 1 Shown, specific embodiment of the present invention and its implementation process are as follows:

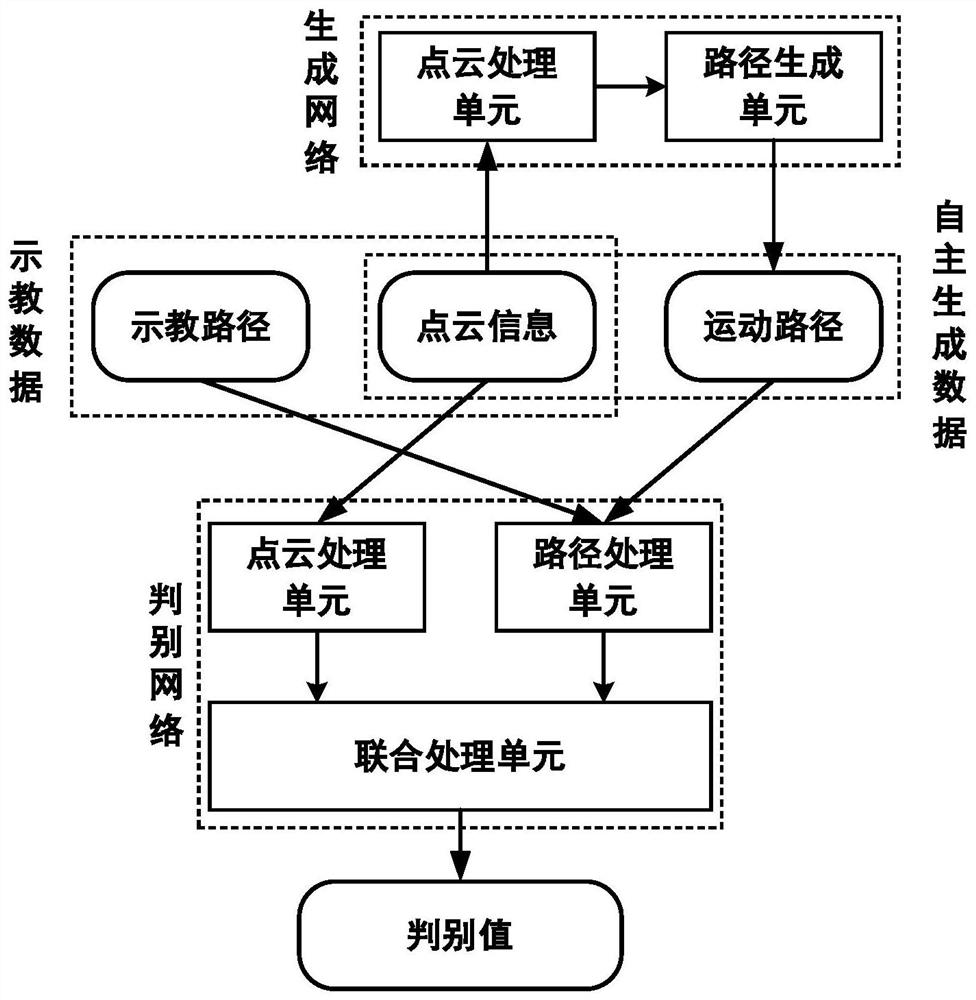

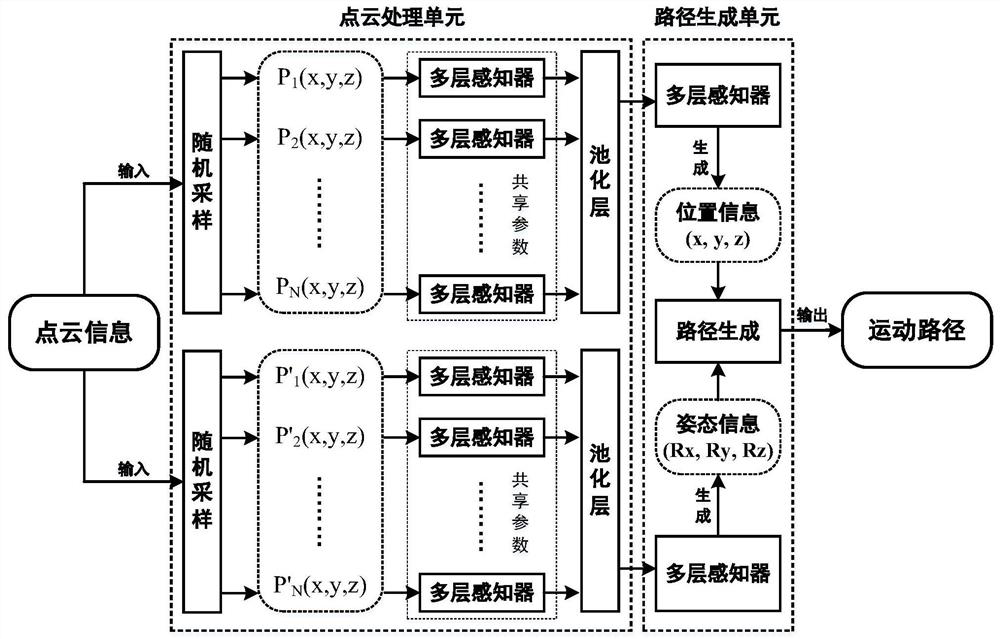

[0043] The depth camera adopts a binocular vision sensor, which is set directly above the object to be captured, and can take pictures of the object to be captured and output point cloud data. The robot is a six-axis industrial robot, which is set on a horizontal plane. The method of the present invention needs to train the point cloud classification network, the position generation network and the attitude generation network first, and the grasping pose estimation can only be implemented after the network training is completed.

[0044]In this method, the tool center point of the robot is set as the clamping midpoint of the end effector, the x-axis direction of the tool center point is the forward direction of the end effector, the z-axis d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com