Impact wrench screwing angle and torque detection, reading and controlling method

An impact wrench and torque control technology, applied to wrenches, manufacturing tools, wrenches, etc., can solve problems such as continuous impact torque that is not easy to detect, achieve the effect of expanding the scope of use and solving precise control problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

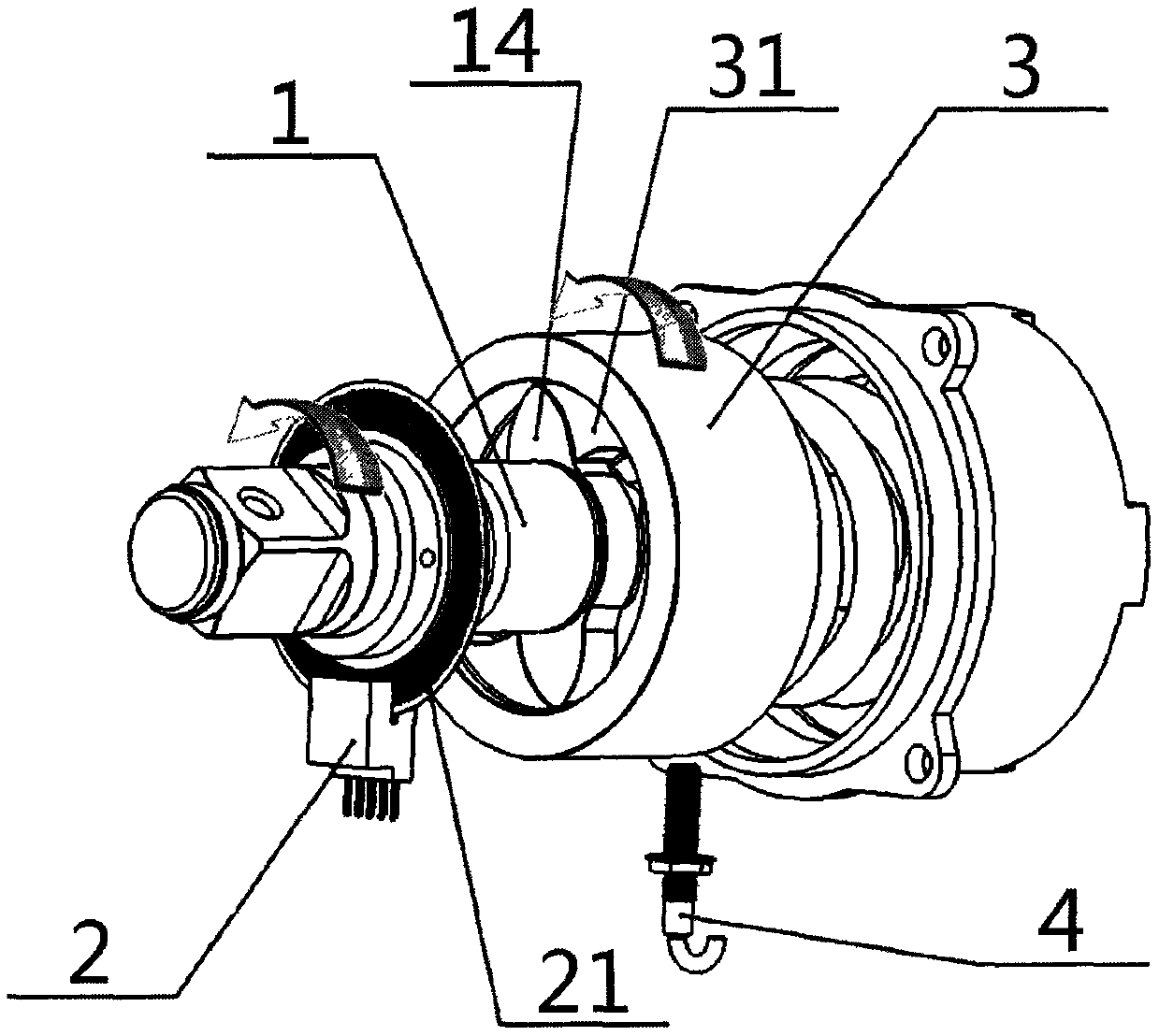

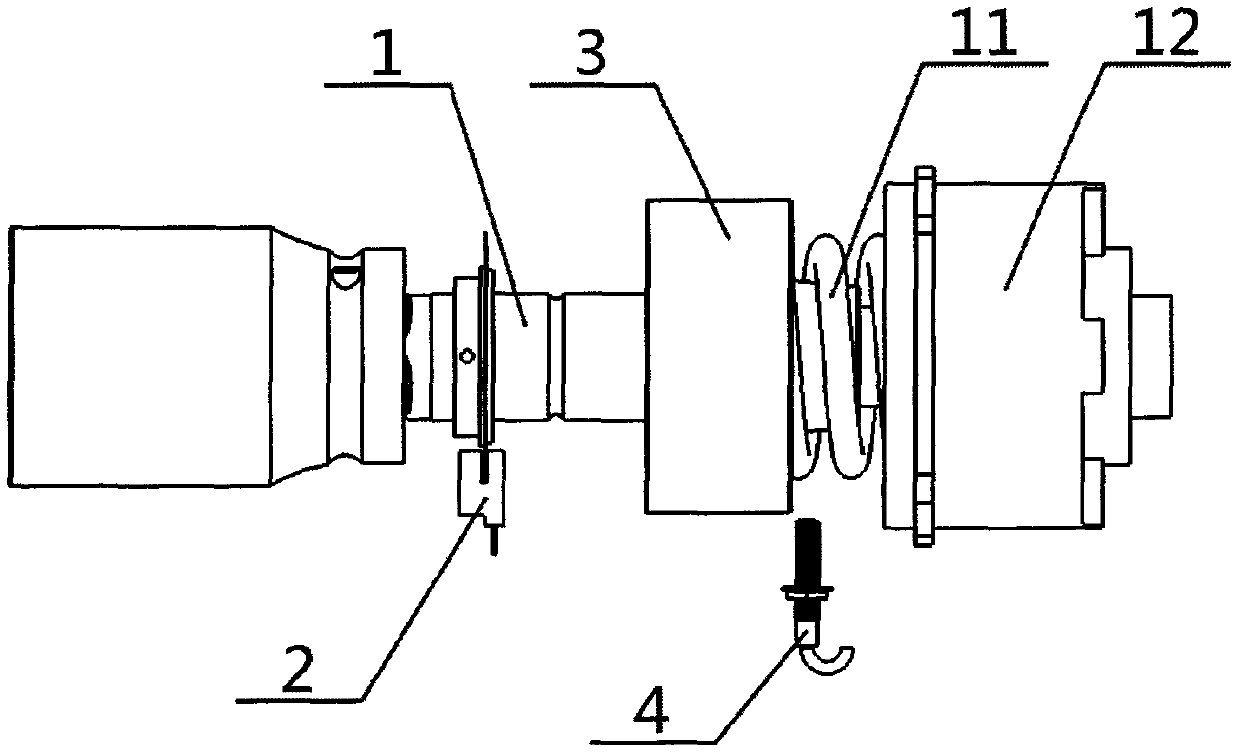

[0021] exist figure 1 and figure 2 Among them, on the output shaft 1 of the known impact wrench structure, the induction disc 21 of the angle detection device 2 is coaxially installed, which is used to output the rotation angle and angular velocity value of the output shaft of the driven part. The impact detection device 4 is installed vertically, which generates a pulse signal with the rotation and impact. After the wrench tightening action starts, the active part of the wrench drives the output shaft 1 of the driven part to rotate, outputting static torque, and the angle detection device 2 outputs the cumulative value of the tightening direction. The number of turns and the angle value are given to the torque controller 6.

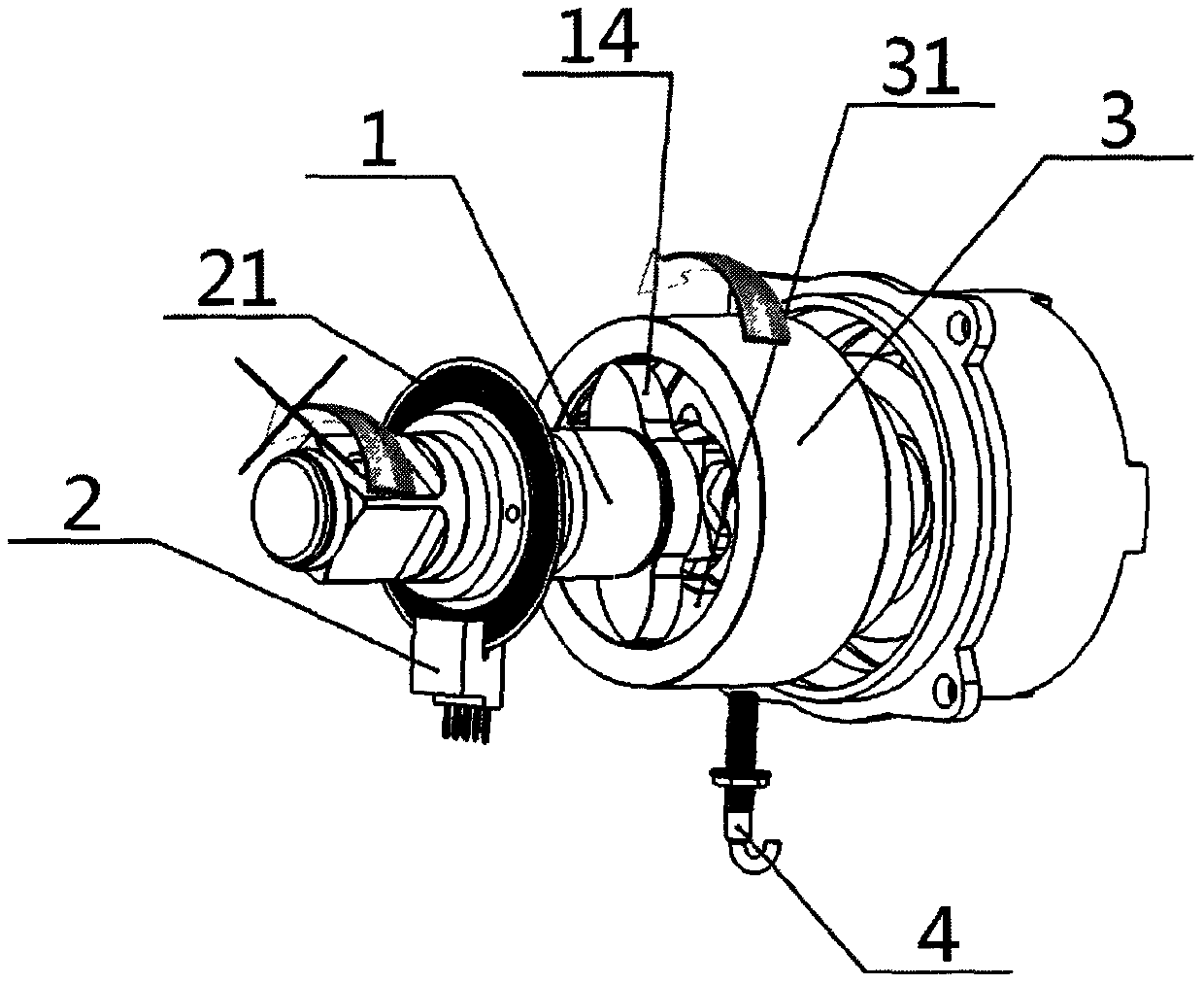

[0022] exist image 3 and Figure 4 In the process, when the wrench reaches the static torque output limit and turns into a rotational impact, the anvil 31 of the active block tooth-embedded structure is separated from the anvil 14 of the driven bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com