Front and back welding process of main shaft based on welding total drive system

A technology of drive system and welding process, applied in welding equipment, welding accessories, manufacturing tools, etc., can solve the problems of large welding current loss, one-time forming of welding seam, and low quality of welding metal, and achieve the effect of high verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

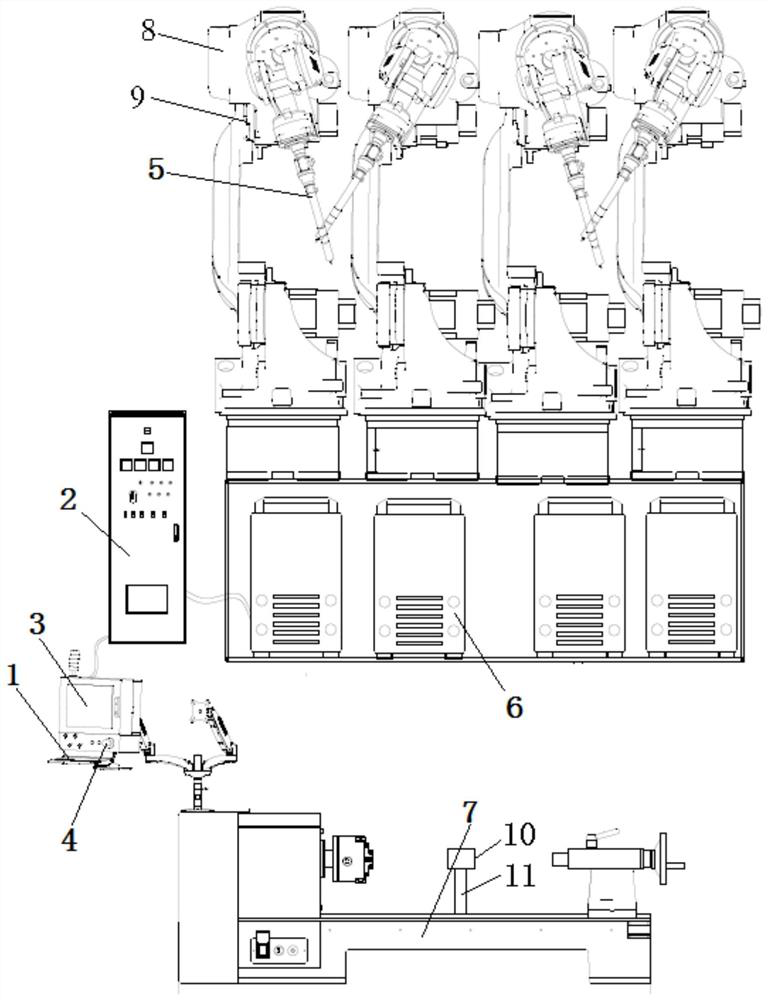

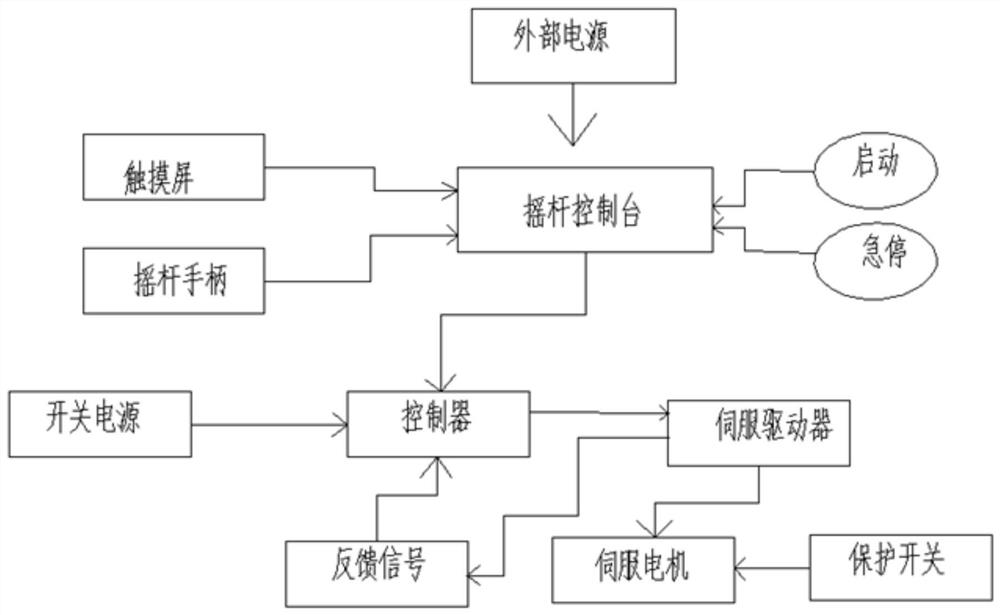

[0078]Example: Refer to the attachedFigure 1-11As shown in 4a, 4a 1, 4a 2, 4b, 4b 1, 4b2, 5a, 5b, the welding process of the front and back of the main shaft based on the welding general drive system includes the following process steps:

[0079]Front welding

[0080]S1: Pre-spell

[0081]Set the large flange and small flange on the main shaft according to the requirements of the drawings, and fix them by spot welding on the non-grooved side;

[0082]S2: Warm up

[0083]Use an oven to preheat the spot-welded spindle at 230°C for 1 hour;

[0084]S3: Spindle 190 degree rotation installation

[0085]Reference attachedFigure 8 ,10As shown, hoist the preheated main shaft and armrest shaft to the welding workstation, and fix the main shaft vertically through a 90-degree fixing device;

[0086]The 90-degree fixing device includes a vertical pile 11, an automatic compactor 10 fixed on the vertical pile 11, and a lower clamp set on the welding workstation, the lower clamp and the automatic compactor 10 up and down ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com