Rice milling machine for agricultural machinery

A technology of agricultural machinery and rice milling machine, applied in agriculture, application, grain finishing, etc., can solve the problem of low working efficiency of rice milling machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

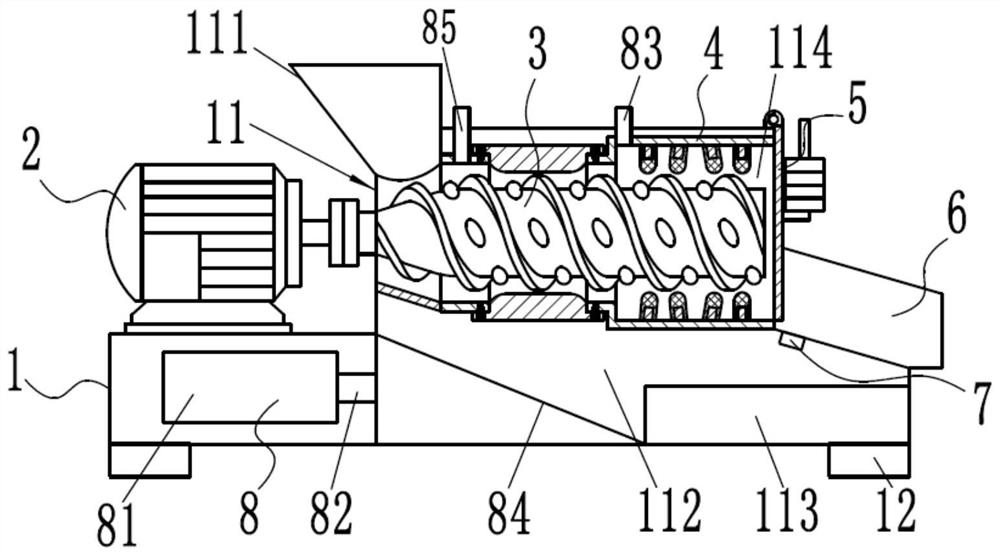

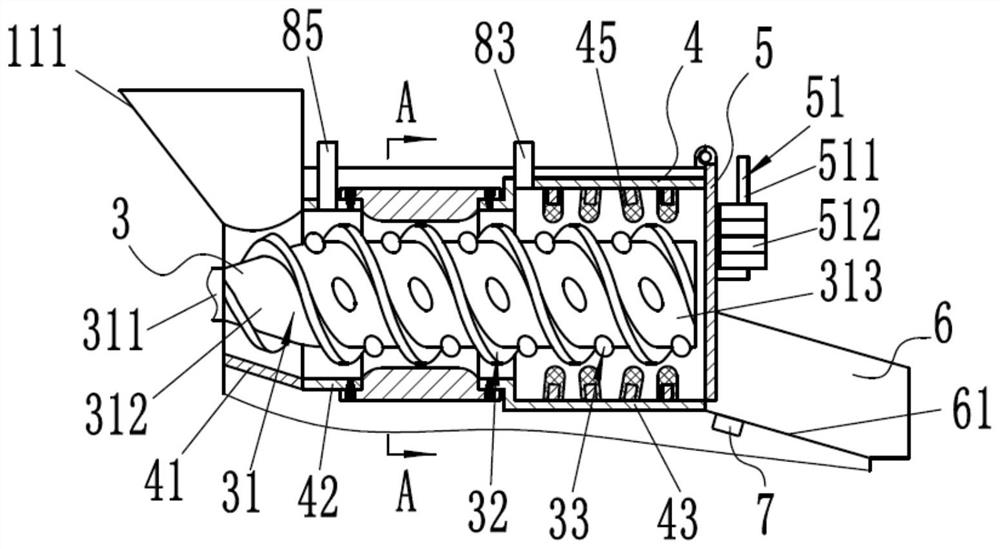

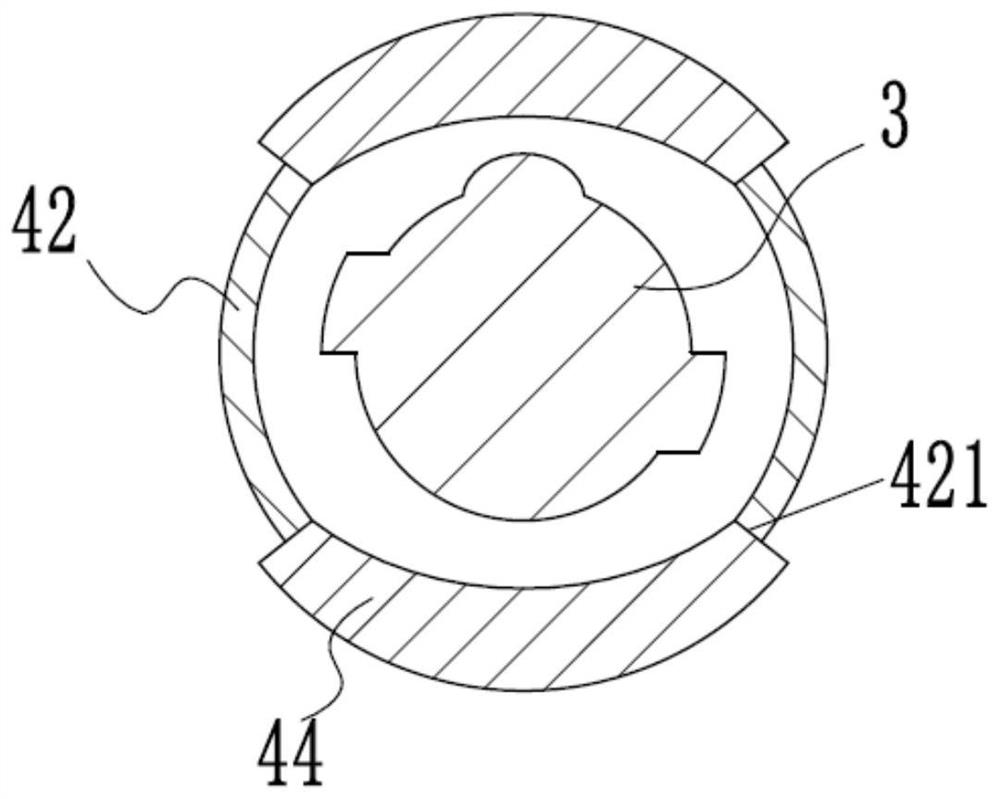

[0026] Refer below Figure 1 to Figure 5 The present invention is further described, as figure 1 The shown rice milling machine for agricultural machinery comprises a body 1, a motor 2, a rice roller 3, a sieve cylinder 4, a sealing cover plate 5 and a hopper 6, the right side of the body 1 has a rice milling box 11, and the rice milling box The left side of the top of 11 is provided with feed hopper 111, and motor 2 is arranged on the body 1, and motor 2 is positioned at the left side of rice milling box 11, and sieve cylinder 4 is arranged on the top inside rice milling box 11, and sieve cylinder 4 will The inside of the rice milling box 11 is divided into a rice milling chamber 114 and a chaff collecting chamber 112. The lower end of the feed ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com