Spray dust removal device

A technology of dust removal device and nozzle, applied in gas treatment, dispersed particle separation, chemical instruments and methods, etc., can solve the problems such as dust cannot be cleaned out in time, nozzle blockage, etc., to achieve good protection effect, prolong service life, and good elasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

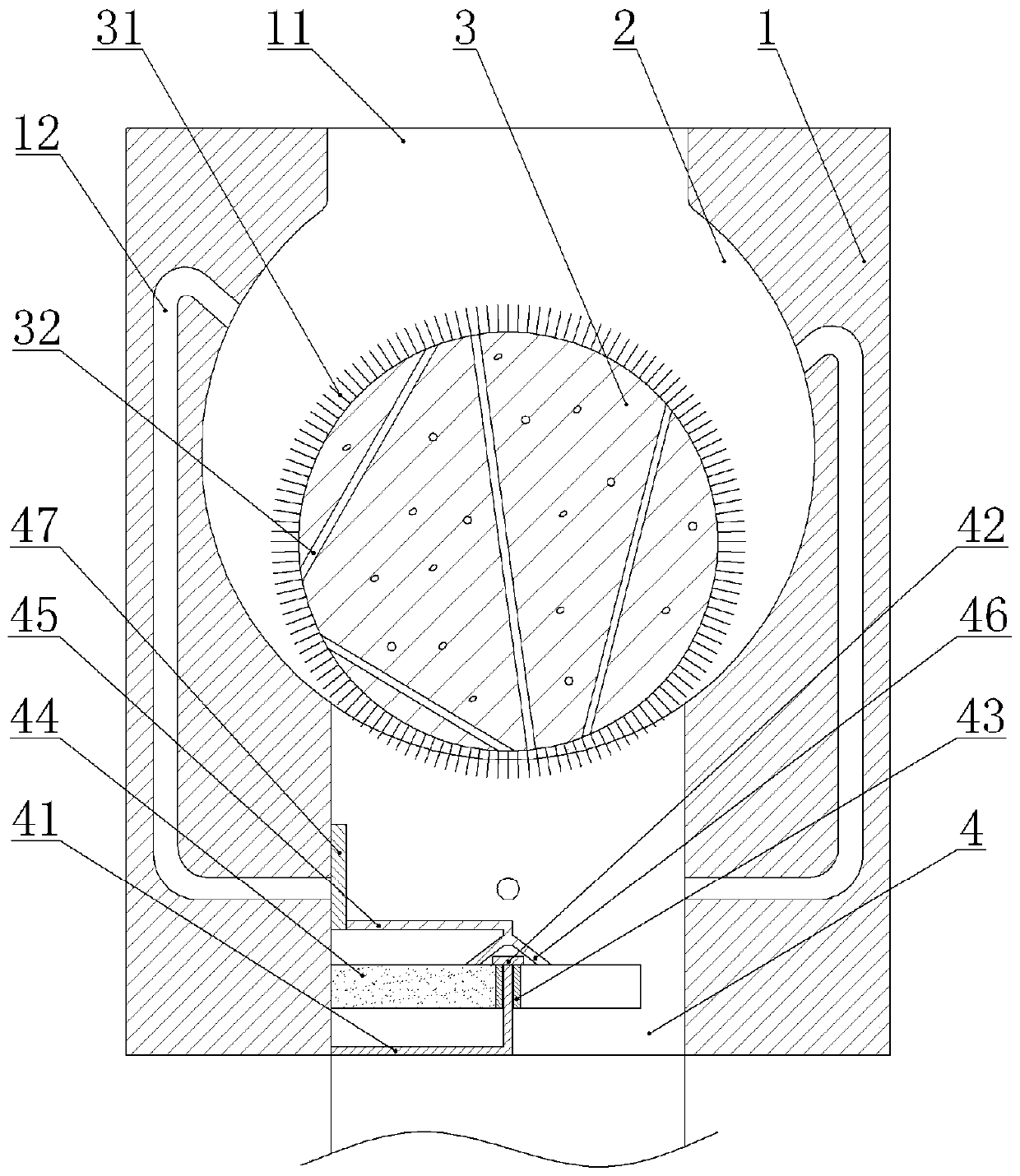

Image

Examples

Embodiment 2

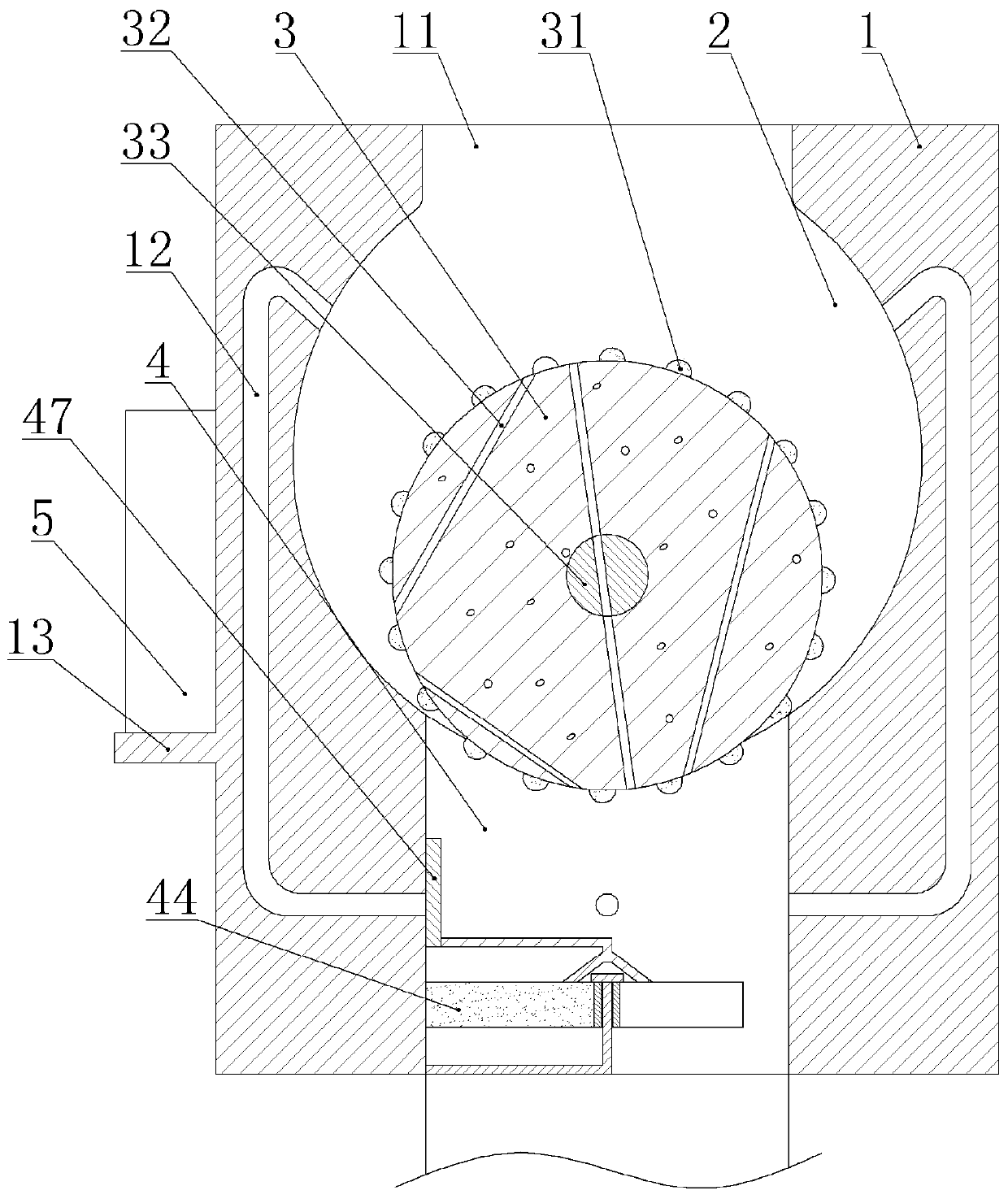

[0041] The flexible part 31 in the present embodiment is different from Embodiment 1, as figure 2 As shown, the flexible piece 31 in this embodiment is an elastic block, specifically, the flexible piece 31 is a rubber block, and the gaps between several flexible pieces 31 are glued on the outer wall of the central body 3, and the end of the air passage 32 is located at the adjacent between the flexible parts 31 to prevent the flexible parts 31 from blocking the air passage 32 .

[0042]And on the basis of Embodiment 1, the left wall of the shower head 1 in this embodiment is integrally formed with a mounting seat 13, and the mounting seat 13 is threaded with an electromagnet 5, and the center body 3 is embedded with an iron block 33. When the electromagnet 5 is working Attract the iron block 33 so that the cleaning ball is adsorbed to the left side of the arc-shaped cavity 2, and the cleaning ball no longer moves relative to the arc-shaped cavity 2.

[0043] The specific imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com