Detection device on a spinning preparation machine and carding bar set intended therefor

A card clothing and machine technology, applied in the field of card clothing, can solve the problems of high cost, increased cost, time-consuming, etc., and achieve the effect of electrical coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

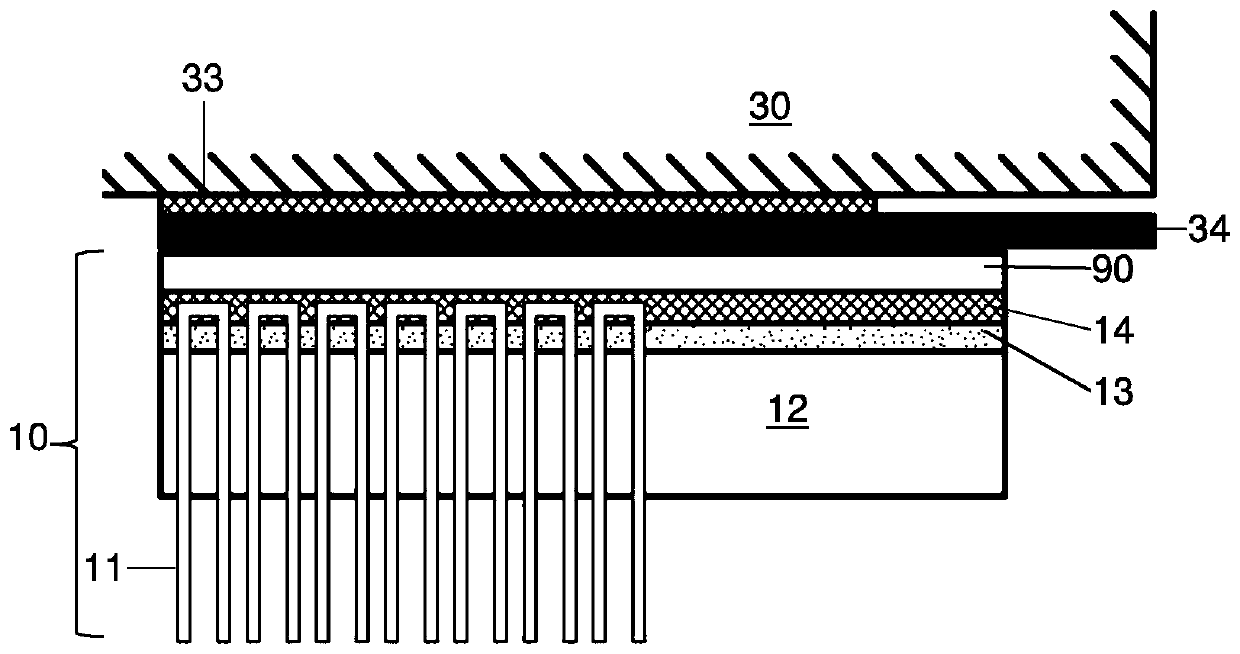

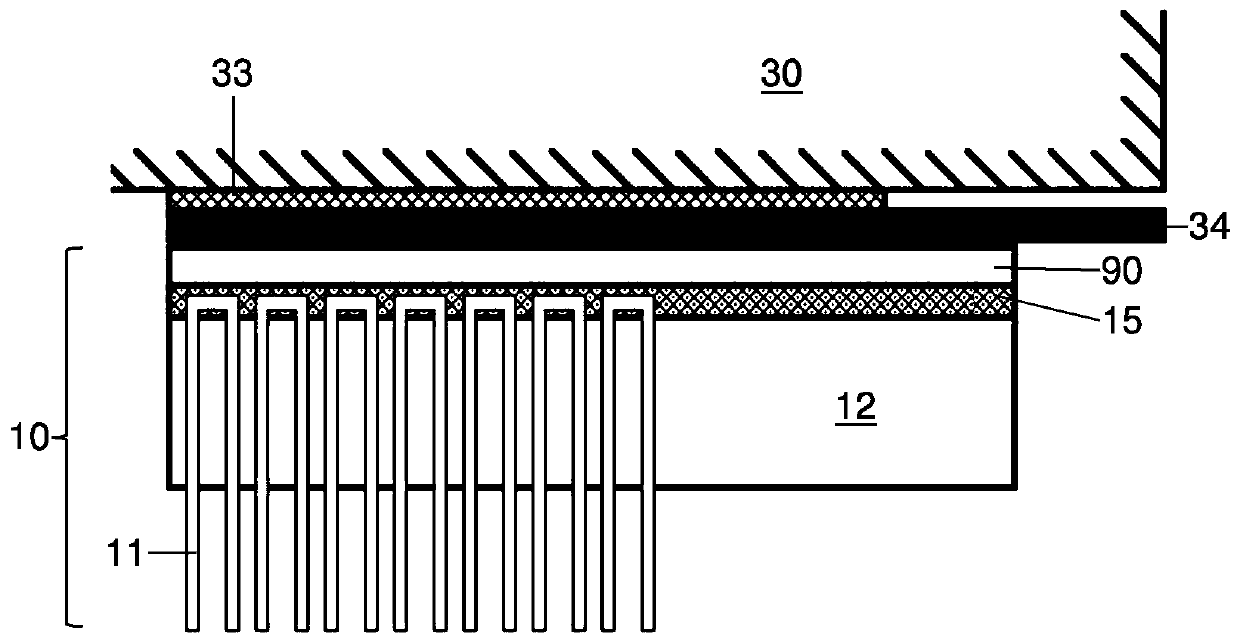

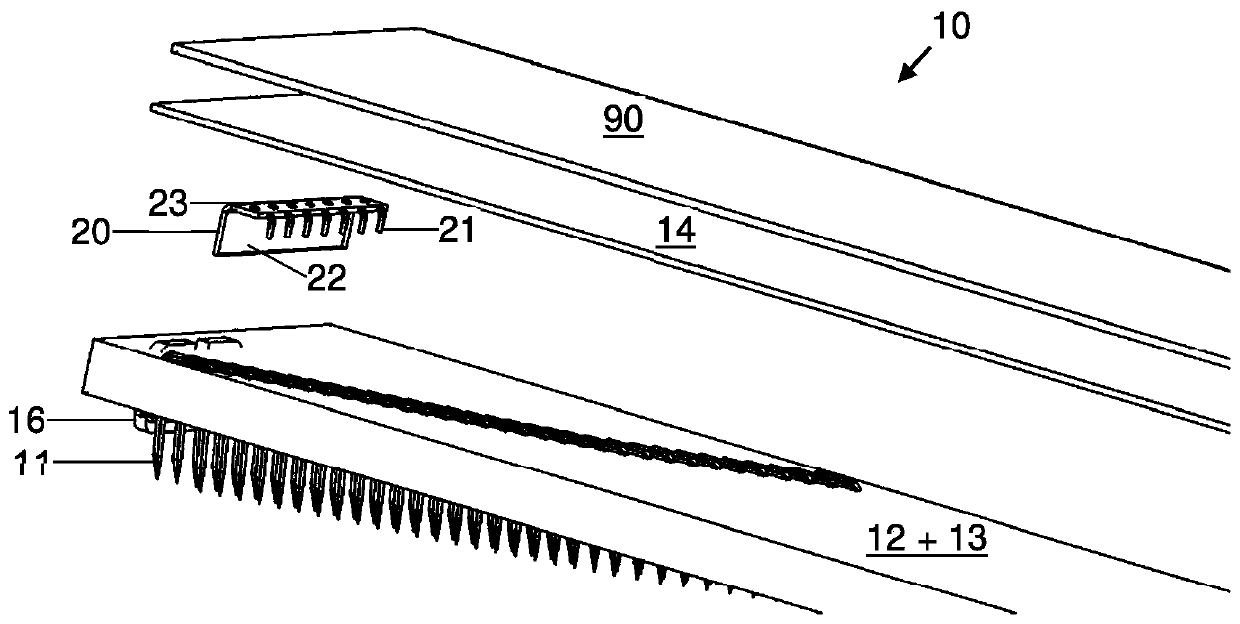

[0046] figure 1 An arrangement with a carrier 30 and a card wire 10 is shown, which is constructed according to the first embodiment of the invention.

[0047] The bracket 30 includes an adhesive layer 33 on which a magnetic strip 34 is mounted. On the side of the card clothing 10 facing the carrier 30 there is a backing plate 90 which consists of a magnetizable material, such as steel. The card clothing 10 is mounted or held on the support 30 via said back plate 90 .

[0048] On the side facing away from the carrier 30 , the backplane 90 is attached to the electrically conductive layer 13 by means of the intermediate layer 14 , here designed as an adhesive layer. On the side of the electrically conductive layer 13 facing away from the support 30 , the base 12 of the clothing 10 is now fastened, which base can consist, for example, of a plurality of layers or of fabric layers glued together. Base 12 is typically constructed from five layers of cotton fabric. Since the base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com