Three-dimensional carving machine

A technology of a three-dimensional engraving machine and a seat body, which is applied in the mechanical field, can solve the problems that the engraving accuracy cannot be guaranteed and the engraving accuracy cannot be improved, and achieve the effects of improving the engraving accuracy, saving the processing cost and improving the processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

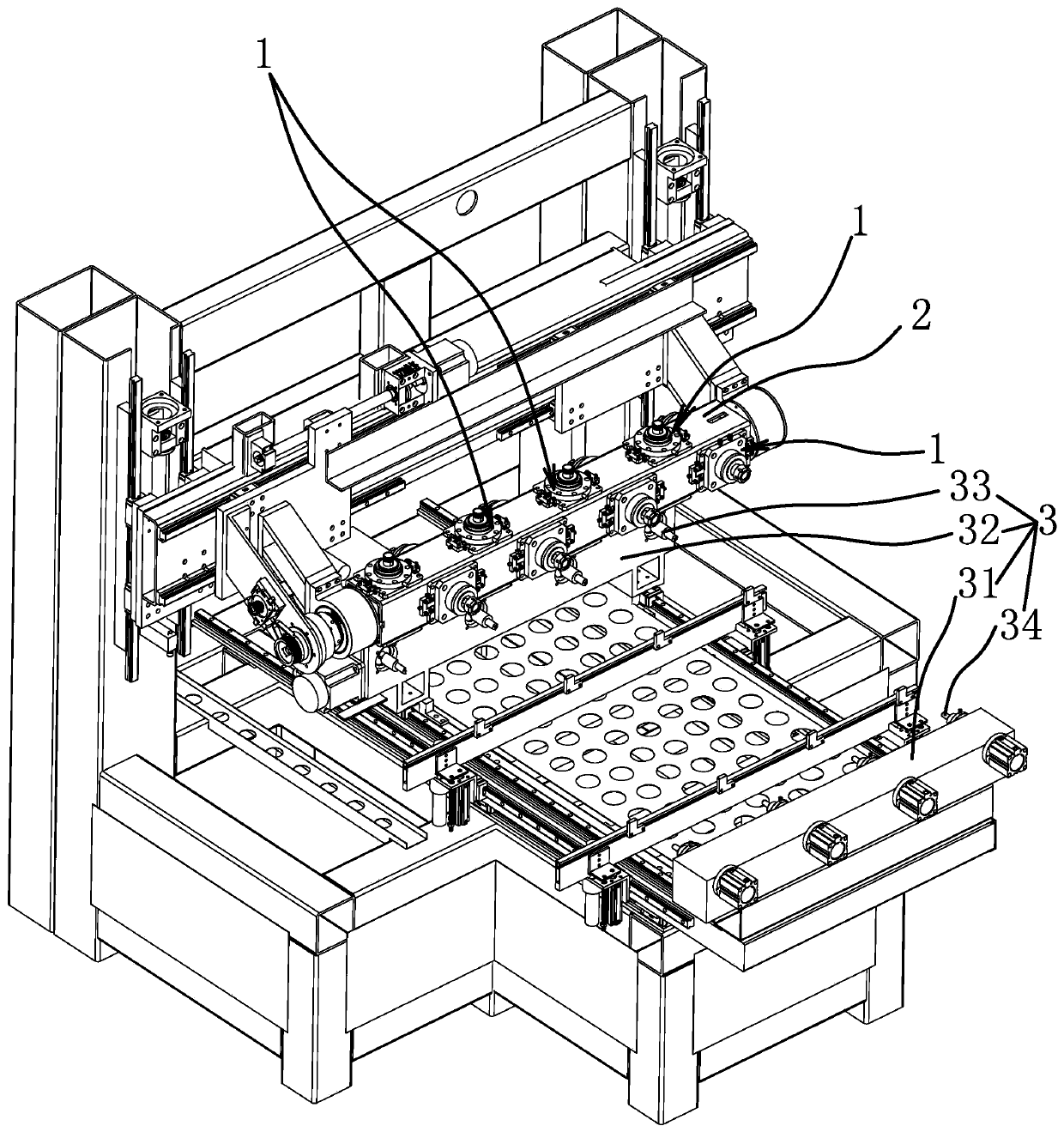

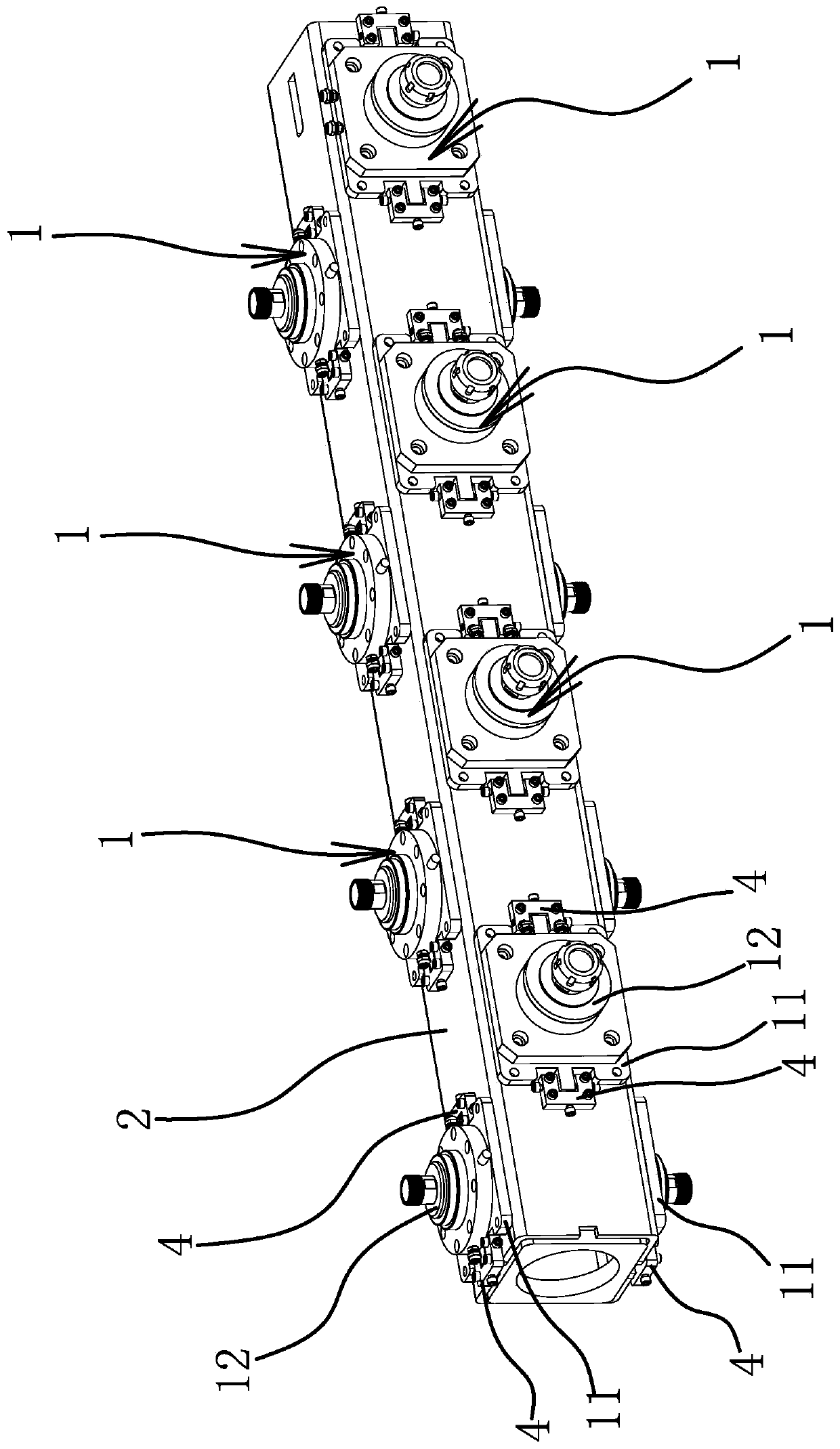

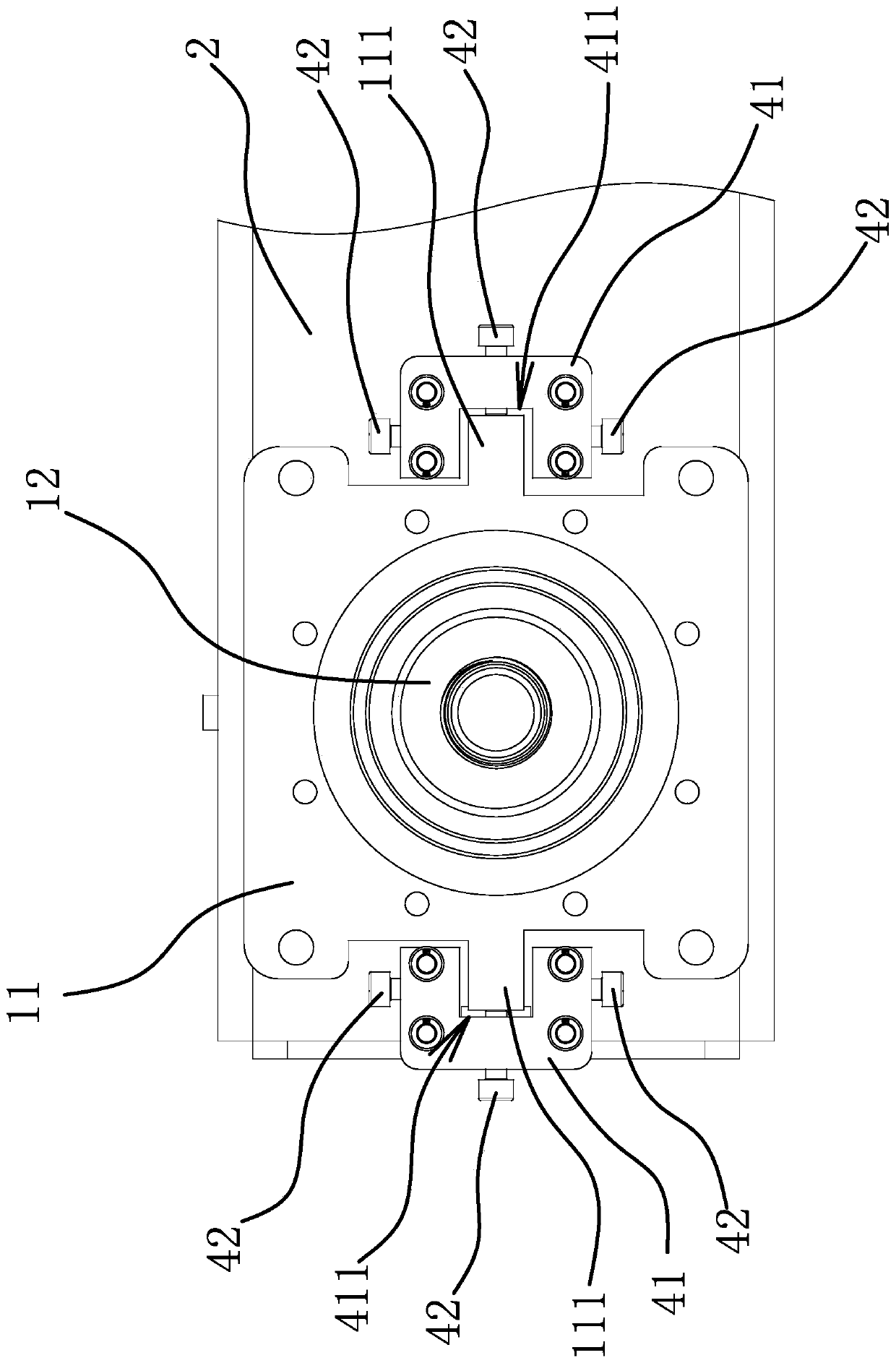

[0034] Specifically, as figure 1 As shown, the three-dimensional engraving machine includes several engraving assemblies 1, a strip tool holder 2 for connecting the engraving assemblies 1, and a clamping assembly 3 for clamping workpieces. The clamping assembly 3 includes a first clamping table 31 and The second clamping platform 32 that can move relative to the first clamping platform 31, the second clamping platform 32 is provided with a number of turntables 33, and the first clamping platform 31 is provided with a number of tops 34 corresponding to the turntables 33 one-to-one . Among them, such as figure 2 and Figure 4 As shown, each engraving assembly 1 includes a base body 11 and a drive motor 12 fixed on the base body 11 for driving the cutter to rotate. There are two base bodies 11 in the engraving assembly 1, and the drive motor 12 of the engraving assembly 1 is passed through the In the tool holder 2, the above two bases 11 are fixedly connected with the flanges...

Embodiment 2

[0038] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, there is no need to design a positioning bump 111, and several above-mentioned positioning screws 42 are respectively arranged on the upper side and the lower side of the seat body 11 , left side and right side, the head of each positioning screw 42 abuts against the seat body 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com