Detection method for image defect of receiver product and detection light source thereof

A detection method and receiver technology, applied in sorting and other directions, can solve the problems that the pit edges cannot be displayed, the slope-shaped pits cannot be displayed, and the pit edges are not obvious, so as to save the manual detection process and save detection The effect of cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

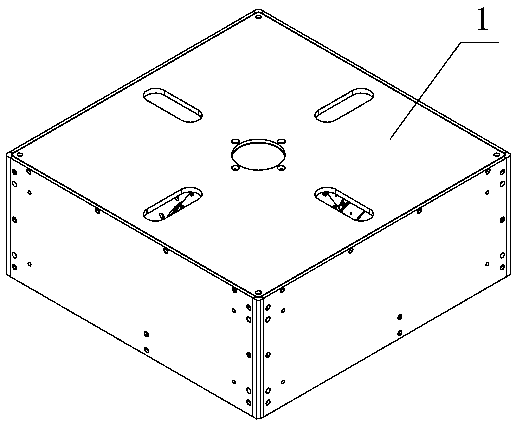

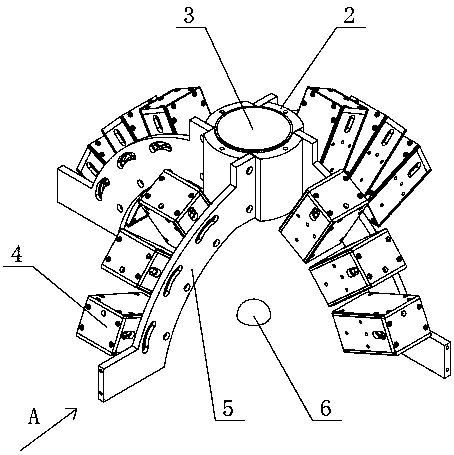

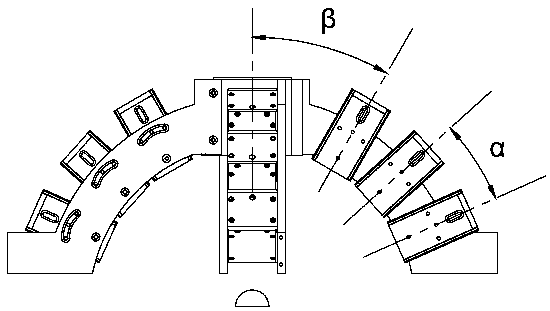

[0027] like Figure 1-3 Shown is a light source for detecting imaging defects of receiver products. The detection light source has a cross-shaped light source fixing bracket, and the outer cover of the light source fixing bracket is provided with a housing 1. The fixing seat 2 in the center of the bracket, the fixing seat 2 is fixedly connected with the housing 1 through screws so as to fix the light source fixing bracket with the housing 1, and the outer wall of the fixing seat 2 is evenly fixed with four downwardly curved curved fixing plates 5, The center of the fixing seat 2 is provided with a camera shooting hole 3, and a light source group is installed on the fixing plate 5. The light source group includes several coaxial light sources 4, and the distance between the central axes of two adjacent coaxial light sources 4 on the same fixing plate 5 The included angle α is 18°, and the included angle β between the central axis of the coaxial light source 4 close to the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com