Lubricating oil residual service life evaluation method based on differential scanning calorimetry

A technology of differential scanning calorimetry and life evaluation, applied in the field of lubricating oil detection, can solve problems such as high disassembly and maintenance costs, loss of parking capacity, and immeasurable comprehensive costs, so as to improve accuracy, expand scope, and estimate The effect of failure time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Oxidation stability test

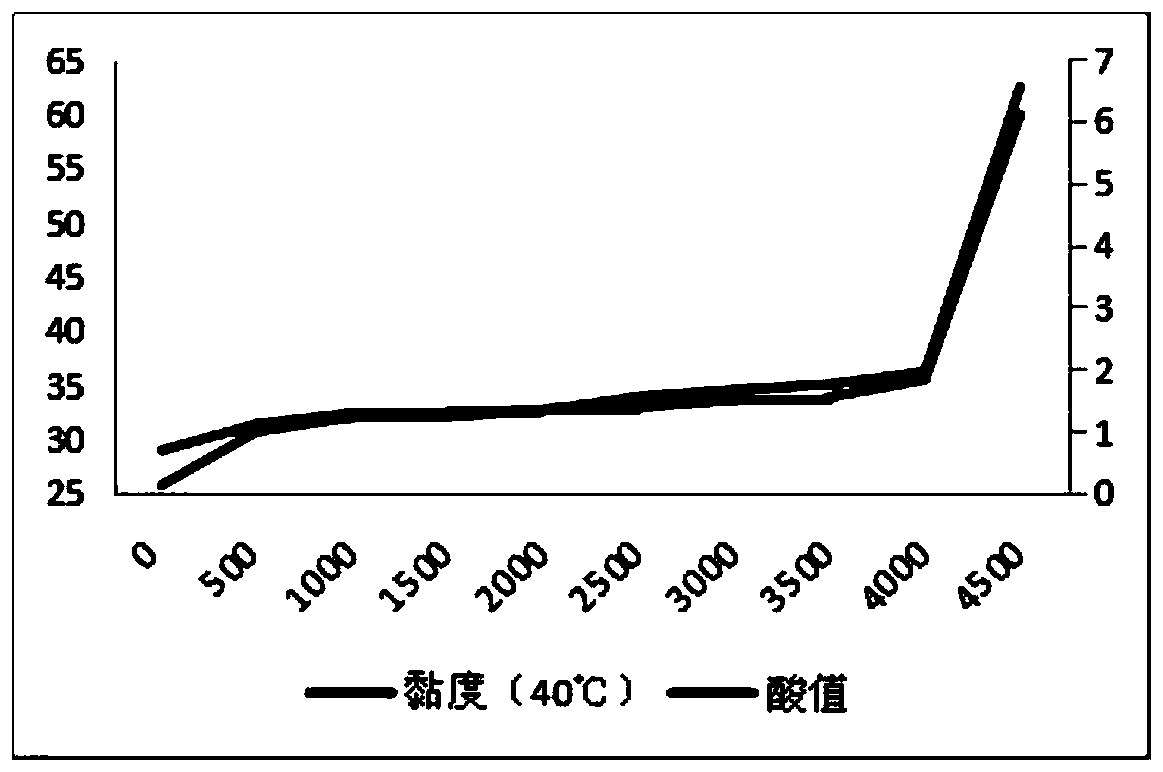

[0043] Select unused transformer oil and conduct oxidation stability test according to the test requirements of GB / T 12581 "Determination of Oxidation Characteristics of Mineral Oil with Inhibitors". In this embodiment, the measuring instrument is JSH3401 plus inhibitor mineral oil oxidation characteristic tester. During the test period, take samples with test time of 0h, 500h, 1000h, 1500h, 2000h, 2500h, 3000h, 3500h, 4000h, and measure their acid value and viscosity at 40°C respectively to obtain a series of data, as shown in Table 1. Plot the corresponding acid value and 40℃ viscosity curve.

[0044] Table 1 Acid value and viscosity under different oxidation time

[0045]

[0046] Such as figure 1 As shown in the figure, as the oxidation time increases, the acid value and viscosity of the oil sample are increasing. The acid value and viscosity of the oil sample in the early stage of oxidation increase slowly. At a certain time of oxid...

Embodiment 2

[0047] Example 2: DSC test

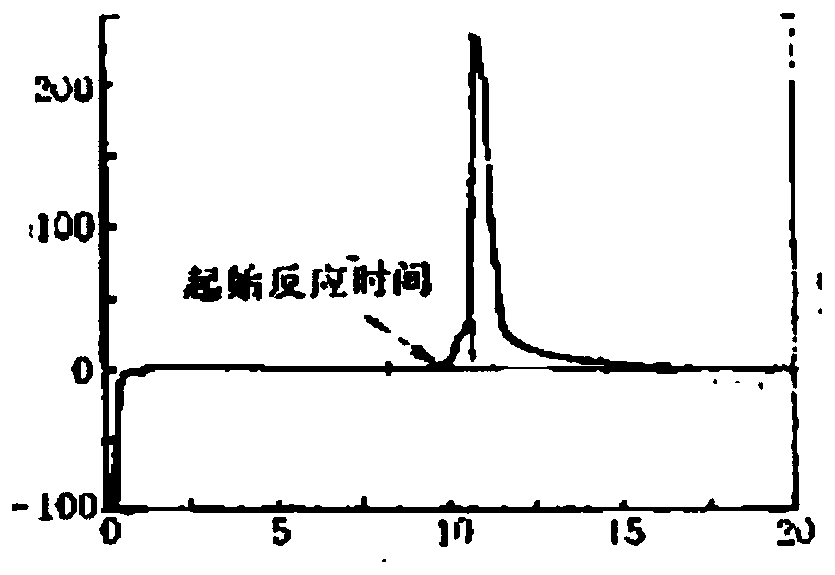

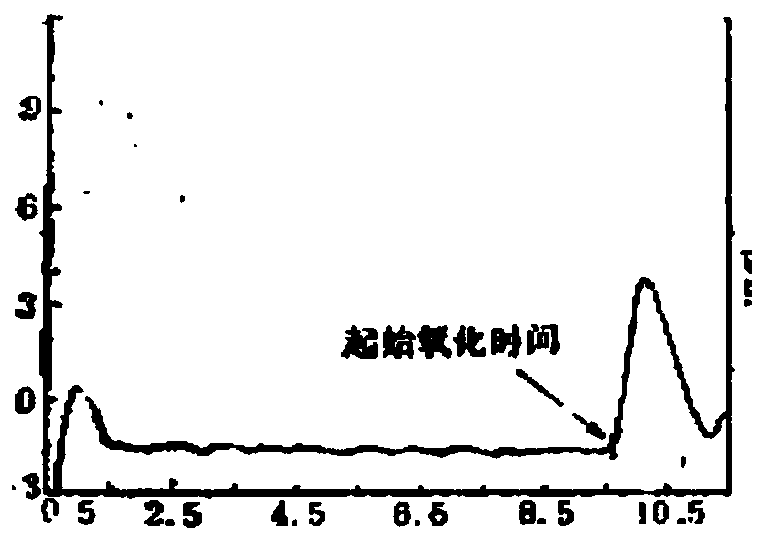

[0048] The number of the unoxidized new oil is 005, and its remaining service life is 100%. The oil sample that has been oxidized for 4000 hours is numbered 001, and its remaining service life is 0%. Take oil samples with oxidation time of 2550 hours, 1750 hours, and 950 hours respectively, numbered 002, 003, and 004. After determining the DSC test conditions, DSC tests were performed on these five samples. In this embodiment, the DSC test uses a DSC-8000 differential scanning calorimeter.

[0049] The temperature condition of DSC test generally has two kinds of constant temperature method and programmed temperature method. In this embodiment, the heat flow curve of the DSC records the power difference between the input to the sample and the reference, and draws the DSC heat flow graph with time or temperature as the abscissa.

[0050] Such as figure 2 versus image 3 Shown, using the constant temperature method under high-pressure oxygen conditions ...

Embodiment 3

[0064] Example 3: Environmental test of tablet pressing

[0065] In order to verify the degree of influence of the oxygen environment on the test results, a comparison test of the sample preparation environment was carried out.

[0066] Such as Picture 9 versus Picture 10 As shown, take samples of unused transformer oil submitted for inspection, take 2 copies of 10ml each, and number them as new oil 5 and new oil 6. The new oil 5 is compressed in an atmospheric air environment, and the new oil 6 is compressed in an atmospheric oxygen environment. Compare the initial oxidation time and the size of the oxidation exothermic peak when the oil sample is degraded in the two maps. It can be clearly seen that the initial oxidation time of the two test samples is about 18 minutes, which can explain that the parallelism of the two test samples meets the conditions; and the exothermic peak of test sample 2 (oxygen environment compression) is larger. Conducive to the observation and analys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com