Thermoelectric refrigeration module life prediction method and device

A thermoelectric refrigeration and life prediction technology, applied in semiconductor working life testing, material thermal development, single semiconductor device testing, etc., can solve problems such as disadvantages, and achieve the effect of improving usability, easy measurement and processing, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

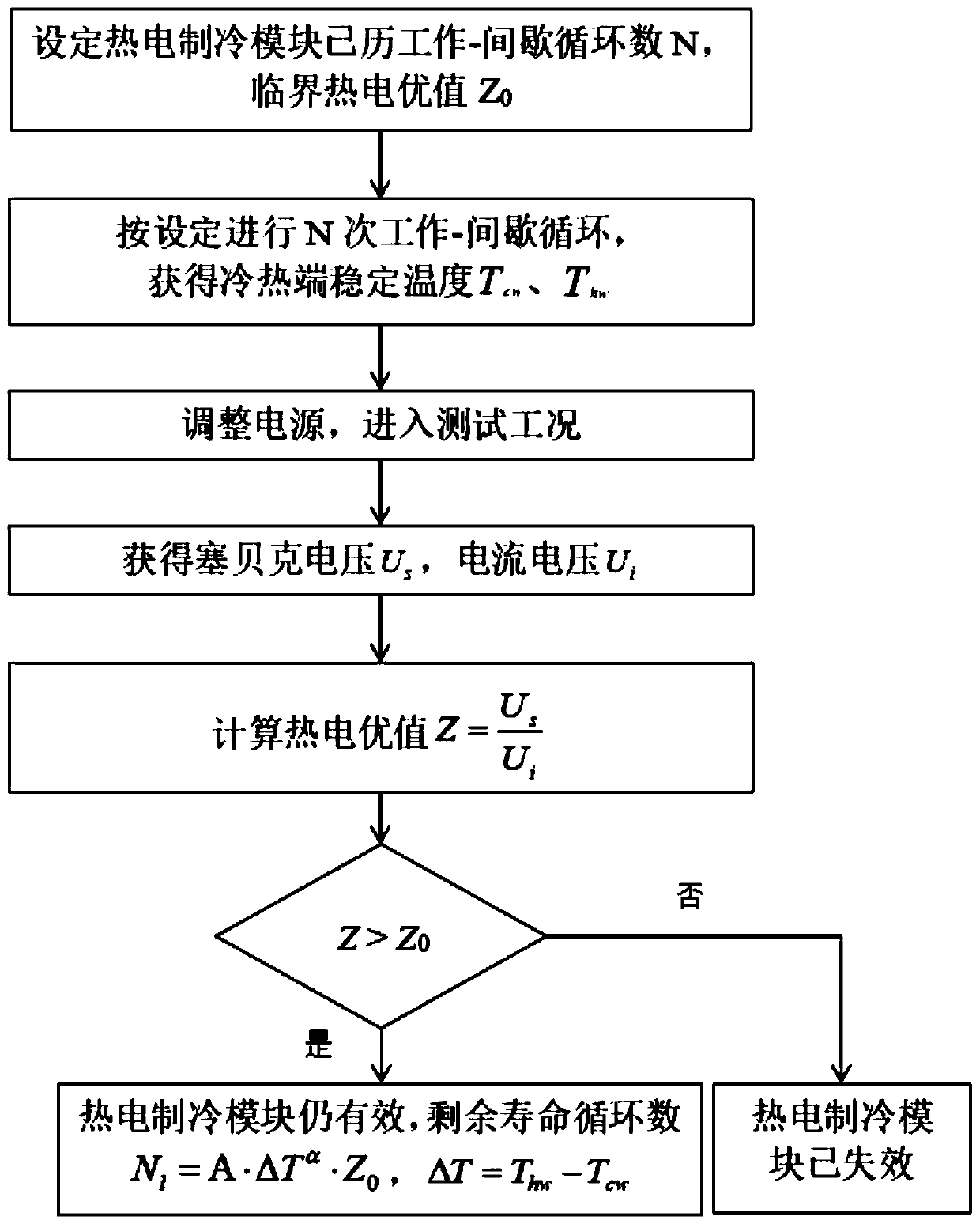

[0042] The preset thermoelectric refrigeration module has worked - the number of intermittent cycles N = 100, the critical thermoelectric figure of merit Z 0 =0.35; the working power supply is a 6V constant voltage power supply, and the test power supply is a 0.2A constant current power supply, specifically including the following steps:

[0043] S1 connects the thermoelectric refrigeration module to the working power supply, and 60s after connecting the working power supply, the thermoelectric refrigeration module works until the temperature of the hot and cold ends reaches a steady state; then disconnects the working power supply, and the temperature of the hot and cold ends of the thermoelectric refrigeration module reaches a steady state 30s after disconnection ;

[0044] S2 repeats S1 100 times, and at the same time measures the stable temperature T of the cold end when the thermoelectric refrigeration module works until the temperature of the hot and cold ends reaches a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com