A cement slurry used in petroleum engineering

A technology for petroleum engineering and cement slurry, applied in the field of cement slurry, can solve the problems of difficulty in meeting high standard requirements, low compressive strength of cement slurry for plugging, etc., and achieve the effect of reducing internal frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A cement slurry used in petroleum engineering consists of the following components by weight:

[0030] 100 parts of oil well G-grade cement, 6 parts of mixed nano-silica, 10 parts of liquid silicon, 24 parts of silicon powder, 8 parts of ultra-fine slag, 0.8 parts of dispersant, 0.8 parts of retarder, and 25 parts of water;

[0031] Wherein, the mixed nano-silica is composed of two different diameters of nano-silica I and nano-silica II with a mass ratio of 1:1, wherein the diameter of nano-silica I is 10-30nm, The diameter of the nano-silica II is 120-140nm; the state of use of the mixed-type nano-silica is nano-silica emulsion, and the solid content of the nano-silica emulsion is 15%.

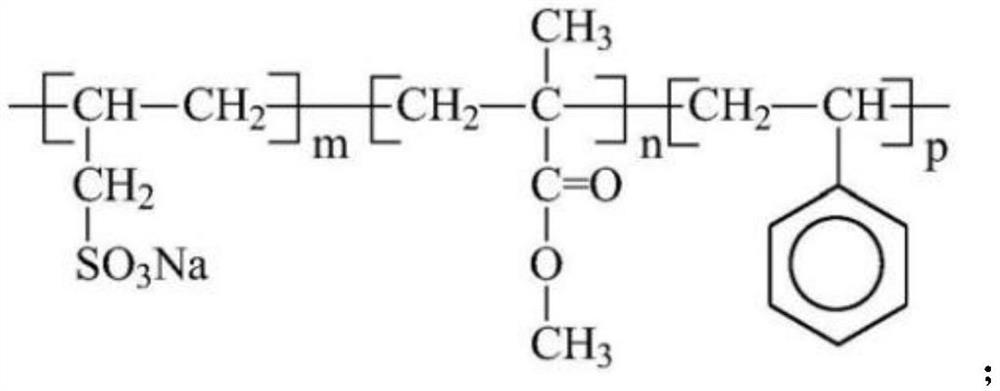

[0032] Wherein, the dispersant is composed of dispersant A and boron modified succinimide according to a mass ratio of 1:1; wherein, the structural formula of dispersant A is:

[0033]

[0034] Wherein, m is an integer of 10-100, n is an integer of 10-100, p is an integer of 10-100...

Embodiment 2

[0044] A cement slurry used in petroleum engineering consists of the following components by weight:

[0045]100 parts of oil well G grade cement, 8 parts of mixed nano silica, 13 parts of liquid silicon, 26 parts of silicon powder, 10 parts of ultrafine slag, 1 part of dispersant, 1 part of retarder, 30 parts of water;

[0046] Wherein, the mixed nano-silica is composed of two different diameters of nano-silica I and nano-silica II with a mass ratio of 1:1, wherein the diameter of nano-silica I is 10-30nm, The diameter of the nano-silica II is 120-140nm; the state of use of the mixed-type nano-silica is nano-silica emulsion, and the solid content of the nano-silica emulsion is 15%.

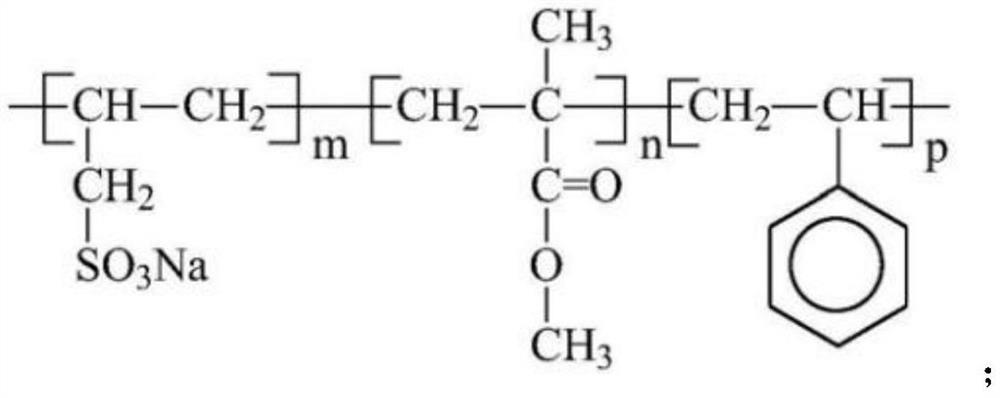

[0047] Wherein, the dispersant is composed of dispersant A and boron modified succinimide according to a mass ratio of 1:1; wherein, the structural formula of dispersant A is:

[0048]

[0049] Wherein, m is an integer of 10-100, n is an integer of 10-100, p is an integer of 10-100, and the m...

Embodiment 3

[0059] A cement slurry used in petroleum engineering consists of the following components by weight:

[0060] 100 parts of oil well G grade cement, 10 parts of mixed nano silica, 15 parts of liquid silicon, 28 parts of silicon powder, 12 parts of ultrafine slag, 1.2 parts of dispersant, 1.2 parts of retarder, 35 parts of water;

[0061] Wherein, the mixed nano-silica is composed of two different diameters of nano-silica I and nano-silica II with a mass ratio of 1:1, wherein the diameter of nano-silica I is 10-30nm, The diameter of the nano-silica II is 120-140nm; the state of use of the mixed-type nano-silica is nano-silica emulsion, and the solid content of the nano-silica emulsion is 15%.

[0062] Wherein, the dispersant is composed of dispersant A and boron modified succinimide according to a mass ratio of 1:1; wherein, the structural formula of dispersant A is:

[0063]

[0064] Wherein, m is an integer of 10-100, n is an integer of 10-100, p is an integer of 10-100, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com