Bad material removing structure

A technology of inner sleeve and outer sleeve, applied in the field of bad material removal structure, to achieve the effect of convenient use, good removal effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

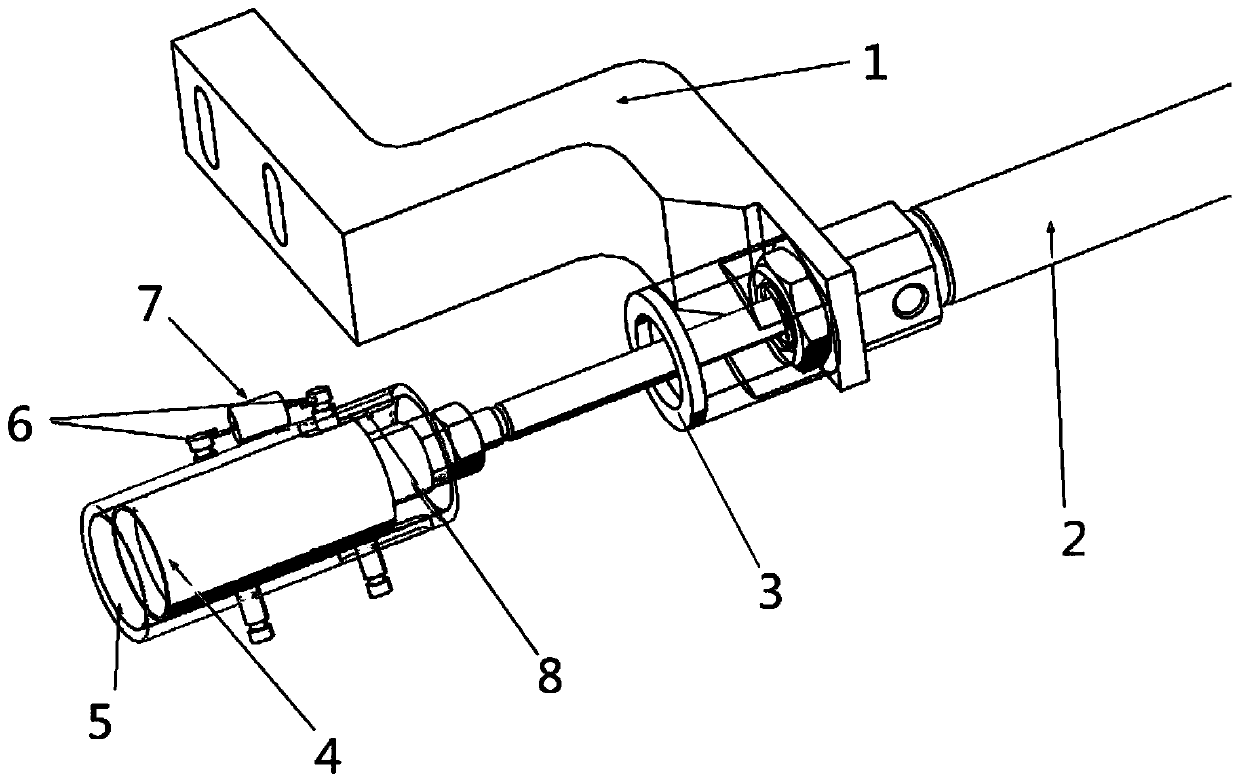

[0017] Example 1: Please refer to figure 1 , a structure for rejecting bad materials, comprising an inner sleeve 4, an outer sleeve 5 slidably connected to each other, and a telescopic cylinder 2 fixedly connected to the mounting base 1, the output end of the telescopic cylinder 2 is fixedly connected to the inner sleeve 4, The telescopic cylinder 2 drives the inner sleeve 4 and the outer sleeve 5 to move forward during the telescopic process. When the outer sleeve 5 contacts the magnetic ring, the telescopic cylinder 2 continues to extend, and the magnetic ring restricts the outer sleeve 5. At this time, the inner sleeve 4 and the outer sleeve 5 move forward. The sleeve 4 moves outward relative to the outer sleeve 5, and the inner sleeve 4 is magnetic, and then attracts with the unqualified magnetic ring. In this case, the relative friction between the outer sleeve 5 and the inner sleeve 4 needs to be small enough , to prevent the outer sleeve 5 from directly pushing the magn...

Embodiment 2

[0023] Embodiment 2: This embodiment is a further improvement of the previous embodiment: the wall of the outer sleeve 5 is provided with an axial hollow hole 8, and the inner sleeve 4 and the outer sleeve 5 are fixedly connected with spring pins. 6. The spring pin 6 on the inner sleeve 4 runs through the hollow hole 8 and the spring pin 6 on the outer sleeve 5 is fixedly connected with a spring 7, and the spring 7 pulls the outer sleeve 5, and after the telescopic cylinder 2 stretches out , the spring 7 directly pulls the outer ends of the inner sleeve 4 and the outer sleeve 5 into a flush state, so as to ensure that the outer sleeve 5 and the inner sleeve 4 release the unqualified magnetic ring at the same time, and prevent the outer sleeve 5 from pushing the magnetic ring to move Case.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com