Agricultural and sideline product crushing device with screening function

A technology for agricultural and sideline products and pulverizing devices, which is applied to grain processing and other directions, can solve the problems of deviation of pulverizing effect, poor screening effect, clogging or damage of pulverizing components, etc., so as to achieve the effect of controlling the amount of cutting material, improving the screening effect, and improving the pulverizing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

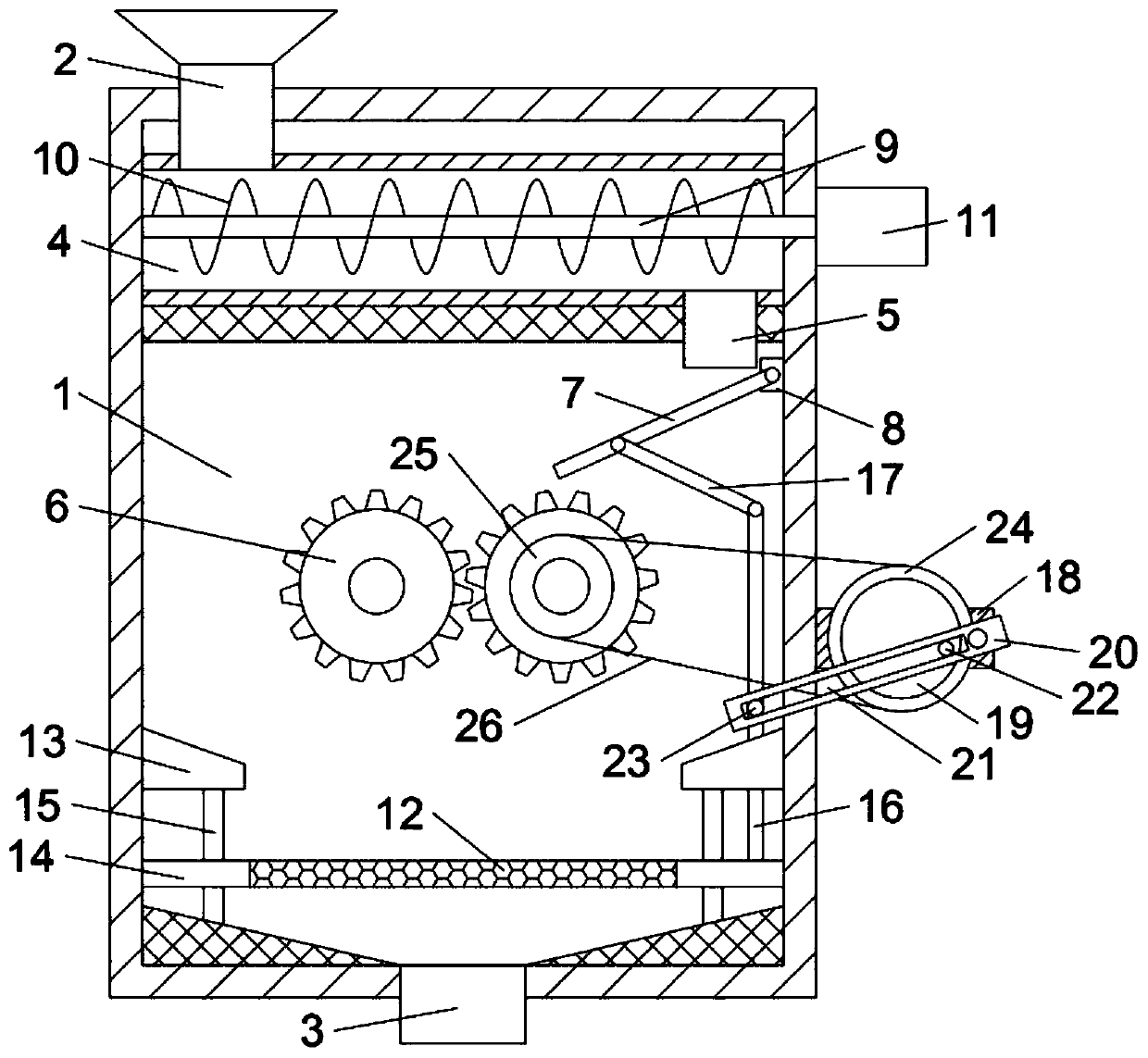

[0025] Refer to attached Figure 1-2 , this embodiment provides a crushing device for agricultural and sideline products with a screening function, including a box body 1, the top and bottom of the box body 1 are respectively provided with a feed hopper 2 and a discharge port 3, and the feed hopper 2 communicates with the material guide pipe 5 through the material delivery assembly, and the material guide tube 5 communicates with the box body 1. Specifically, the conveying assembly includes a conveying chamber 4 and a first rotating shaft 9, the conveying chamber 4 is installed in the box 1, and is located above the crushing assembly; the feeding hopper 2 passes through the The material chamber 4 communicates with the feed pipe 5, and the first rotating shaft 9 is rotatably installed in the feeding chamber 4, and the first screw blade 10 is installed on the first rotating shaft 9, and the first rotating shaft 9 is also It passes through the box body 1 and is fixedly connected...

Embodiment 2

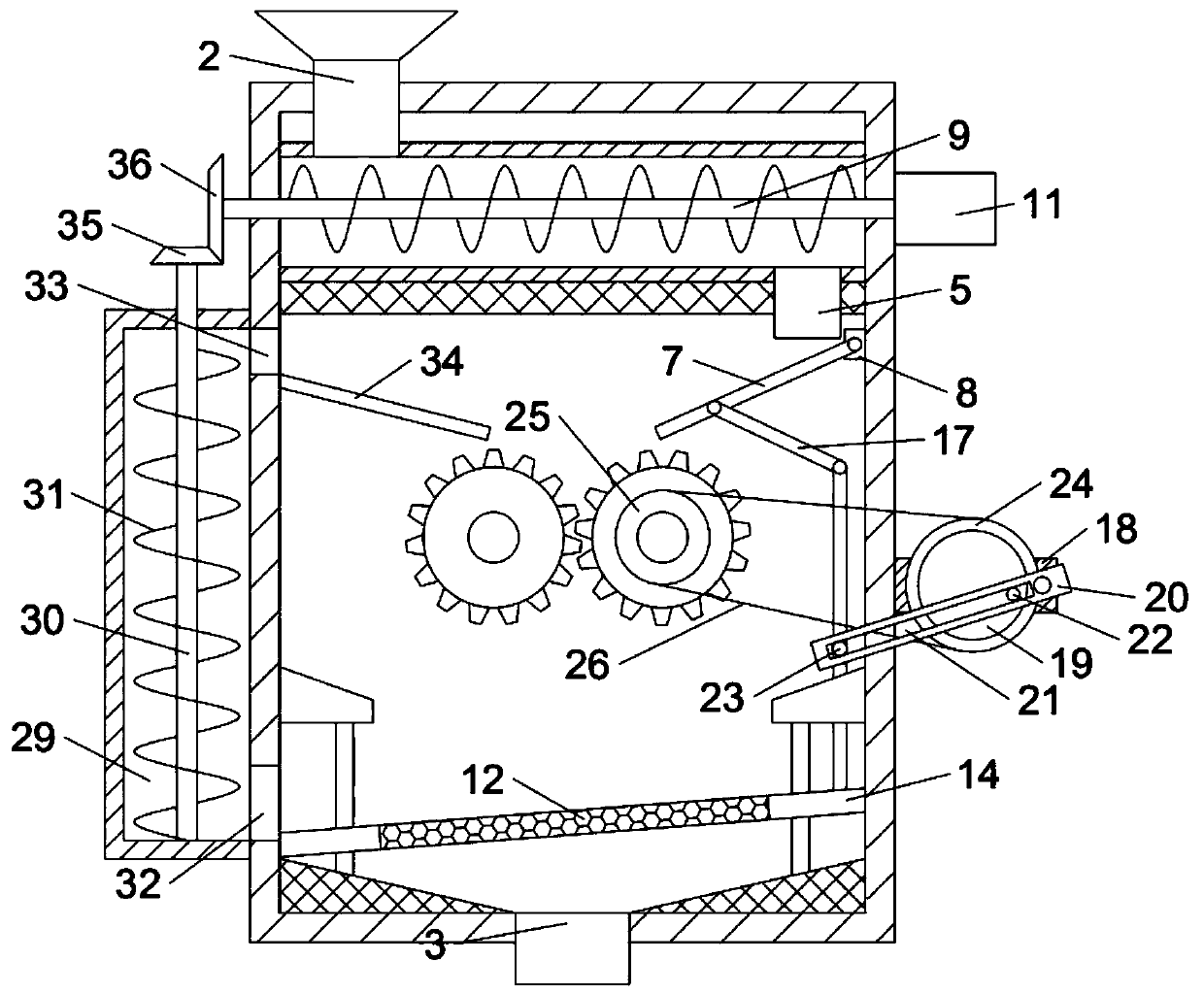

[0033] Refer to attached image 3 , in order to facilitate the realization of circular crushing operation, this embodiment is improved on the basis of embodiment 1, specifically, the screen 12 is installed obliquely between two sets of sliders 14, one of the box 1 The side is also equipped with a circulation chamber 29, the bottom and the top of the circulation chamber 29 are respectively provided with a circulation chamber inlet 32 and a circulation chamber outlet 33, and the circulation chamber inlet 32 and the circulation chamber outlet 33 are all communicated with the casing 1; wherein The connection between the inlet 32 of the circulation chamber and the box body 1 is located on the side of the lower end of the screen 12, and the connection between the outlet 33 of the circulation chamber and the box body 1 is located on the side of the higher end of the material guide plate 34. The material guide plate 34 is obliquely fixed on the inner wall of the box body 1, so t...

Embodiment 1-2

[0035] In combination with Embodiment 1-2, the crushing device provided by the embodiment of the present invention, when in use, first add materials such as agricultural and sideline products into the hopper 2; then, start the first motor 11 and the second motor 27, and the materials can be Transport along the baffle plate 7 to two groups of crushing rollers 6 for crushing operation; at the same time, the screen 12 can move up and down reciprocatingly to efficiently screen the crushed materials; among them, the finer qualified products can be screened out. It is directly discharged from the discharge port 3, and the coarser material screened out enters the circulation chamber 29 along the screen 12, and can be circulated between the two sets of crushing rollers 6 through the circulation assembly for circular crushing.

[0036] In summary, in the embodiment of the present invention, a rotatable baffle 7 is arranged under the material guide tube 5, and the baffle 7 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com