An automatic processing system and method for a hollow fiber membrane module

A processing system and fiber membrane technology, applied in the field of membrane module processing, can solve the problems of unsuitable automatic processing of high packing density modules, random arrangement of membrane filaments, and no automation involved, so as to achieve automatic production, reduce manual intervention, and use The effect of less consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

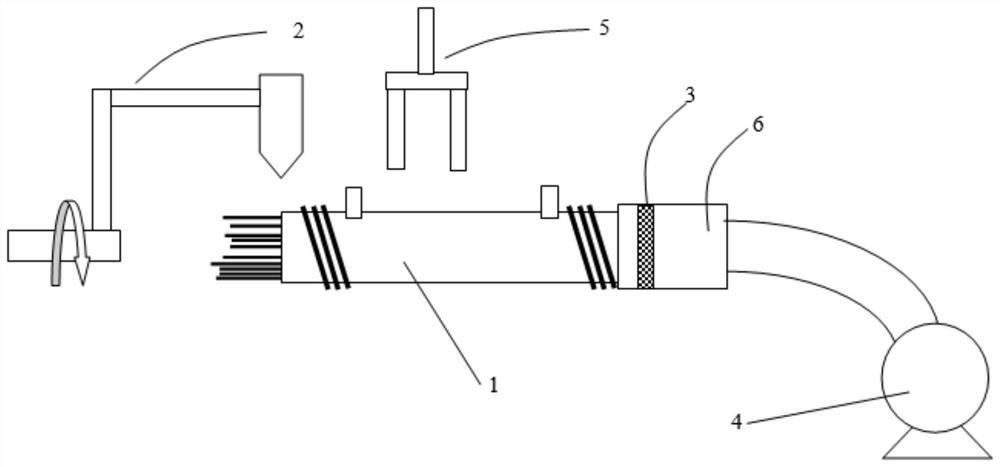

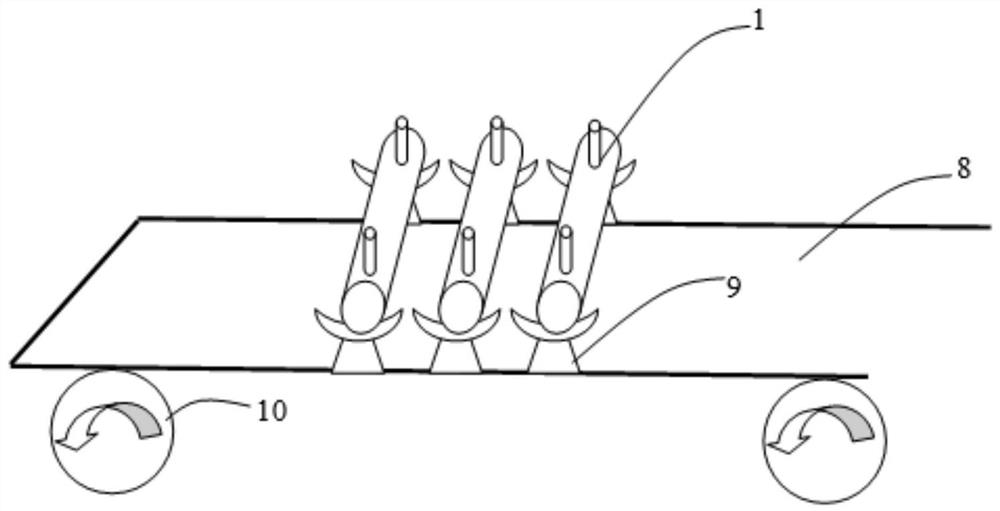

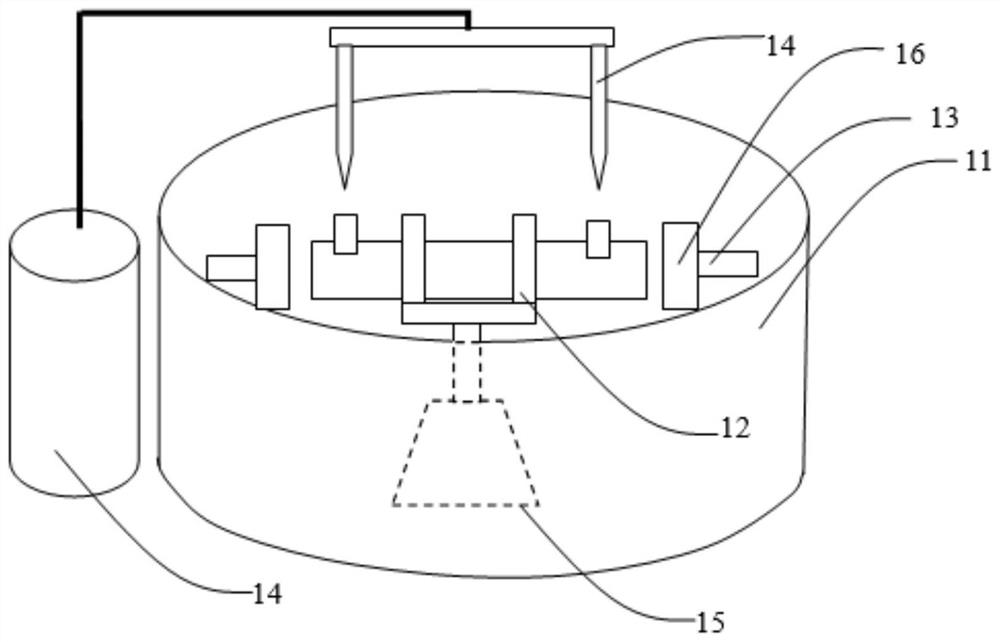

[0034] Such as Figure 1 to Figure 3 As shown, an automatic processing system for a hollow fiber membrane module provided by the present invention includes: a membrane filament accommodation chamber 1, a membrane filament filling device, a coil transmission device and a membrane filament packaging device, and the membrane filament filling device and membrane filament packaging The devices are respectively arranged at both ends of the consolidation transmission device;

[0035] Wherein, the membrane filament accommodating cavity 1 is the main body part of the shell of the hollow fiber membrane module, and is a mold commonly used in the production process of the hollow fiber membrane module. In this embodiment, the structure of the membrane filament accommodating cavity 1 is modified. Improvements to automate production. Specifically, in this embodiment, one or more axially penetrating holes are provided in the membrane filament accommodating chamber 1, and the holes are used t...

Embodiment 2

[0053] This embodiment provides a method for automatic processing of hollow fiber membrane modules using the system described in Embodiment 1, which is characterized in that it includes the following steps:

[0054] S1. Membrane loading: screw one end of the membrane accommodating chamber 1 into the detachable joint 6 through the first manipulator 5, so that the two threads are fastened, and a certain amount of membrane is sent into the membrane accommodating chamber 1 ;

[0055] S2. Membrane alignment: start the centrifugal fan 4 to align the ends of the membrane filaments in the membrane filament accommodating chamber 1; after the centrifugal fan 4 starts for one end, the laser cutting mechanism 2 exposes the other end of the membrane filament accommodating chamber 1 The end of the membrane filament is cut so that the other end of the membrane filament is aligned;

[0056] S3. Conveyance of the membrane filament accommodating cavity: the first manipulator 5 unscrews the mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com