Assembly tightening process sample collection system, deep learning network and monitoring system

A technology of deep learning network and sample collection, which is applied in the field of deep learning network and monitoring system, and sample collection system in the assembly and tightening process, which can solve the problem of not being able to notify the on-site assembly workers of abnormal situations at the first time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

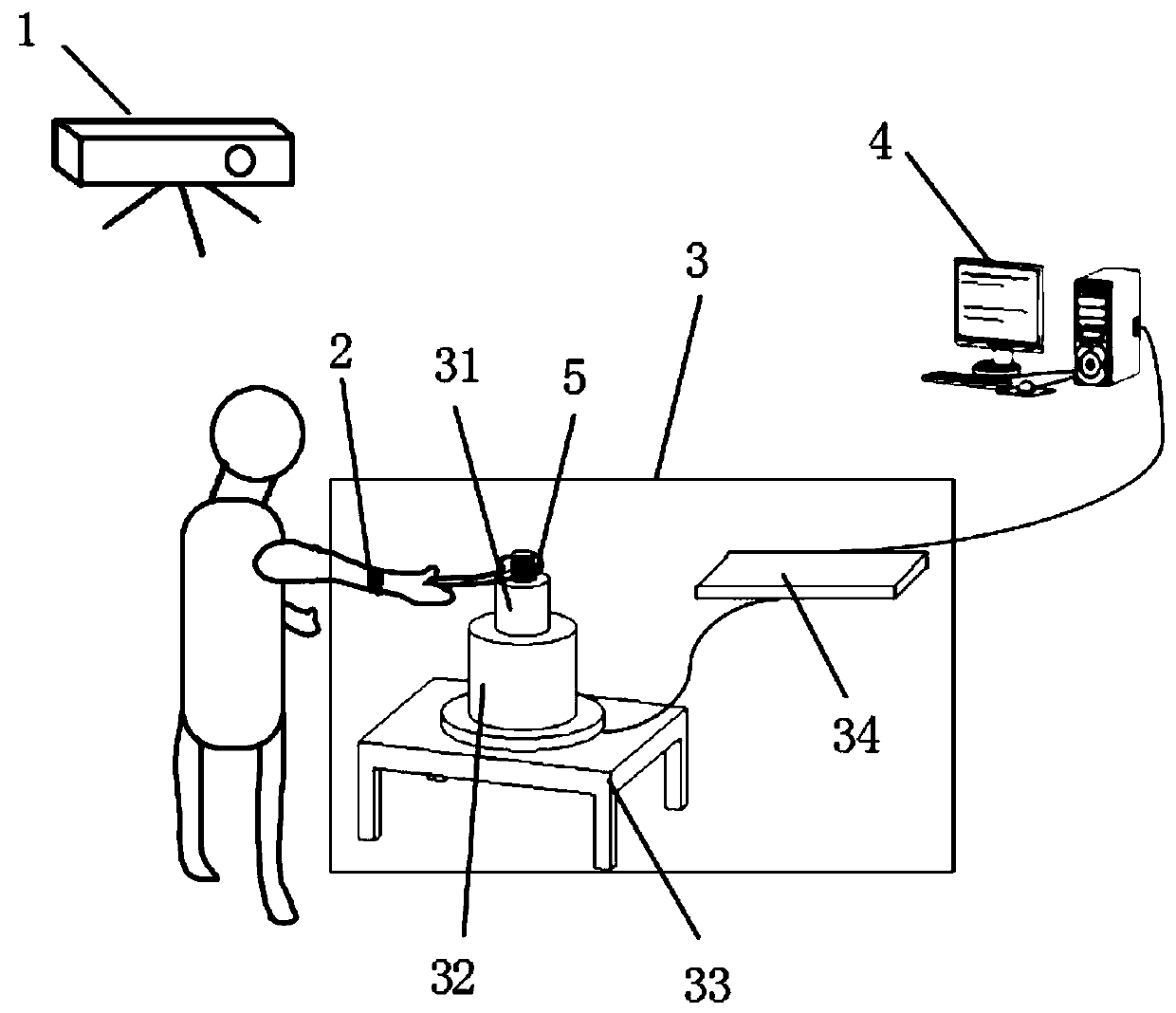

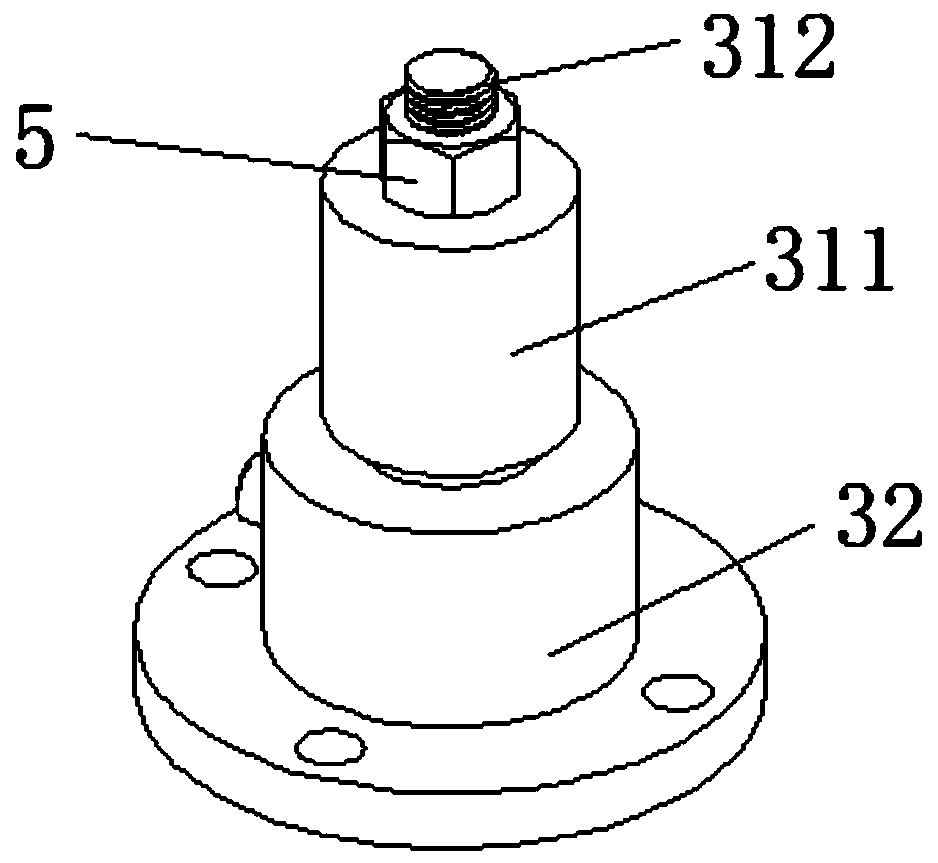

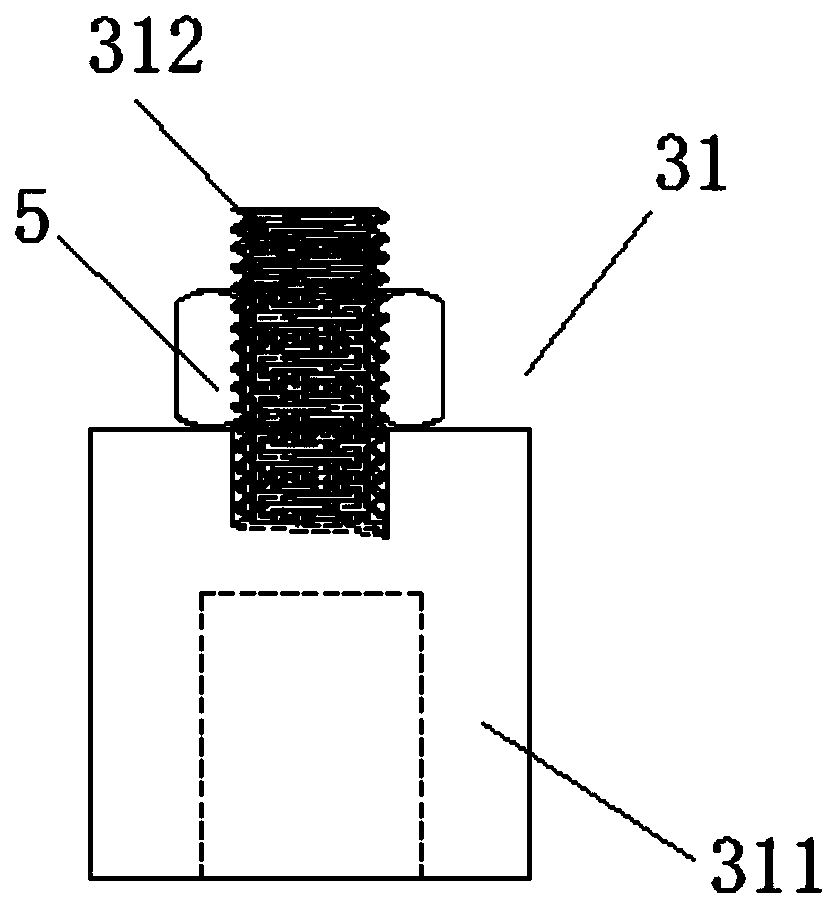

[0035] see figure 1, assembling a tightening process sample collection system, including a video collection device 1, a wearable myoelectric device 2, a torque collection device 3 and a first computer 4, and the video collection device 1 collects video information and sends it to the first computer 4, so The myoelectric device 2 collects the myoelectric signals, inertial acceleration signals and orientation signals of the human body, and then sends them to the first computer 4, and the torque collection device 3 sends the collected torque information when the operator tightens the nut to the The first computer 4, the first computer 4 performs the following steps: identify the skeletal nodes of the human body in the video information, and calculate the coordinate information of each skeletal node; , orientation signal, torque information, and video information are all stored according to time tags; pictures are extracted from video information by time tags, and the pictures, my...

Embodiment 2

[0049] see Figure 4 , a deep learning network, using the sample library obtained by the sample collection system of embodiment 1, and training through the following training steps: using part of the sample data in the sample library as a training set, and dividing the sample data in the training set into multiple groups; The deep learning network includes an input layer, an output layer, a convolutional layer, and a fully connected layer. First, the input layer receives a set of integrated information sets and image information sets, and the sample data in the set of integrated information sets are subjected to the first volume The convolution operation of the product layer is expanded through the first fully connected layer to obtain the first one-dimensional feature value. The sample data of the set of image information is subjected to the convolution operation of the second convolution layer, and then passed through the second fully connected layer. After the connection la...

Embodiment 3

[0054] see Figure 6 and Figure 7 , a monitoring system for the assembly and tightening process, including an image acquisition device 6, an electromyography wearable device 7 and a second computer 8, the image acquisition device 6 collects and monitors the operation video of the on-site operator when assembling and tightening and converts it according to the set number of frames It is an image, and then sent to the second computer 8, the myoelectric wearable device 7 collects the myoelectric signal, inertial acceleration signal and orientation signal of the human body, and then sends it to the second computer 8, and the second computer 8 loads the embodiment In the deep learning network in the second, the second computer 8 performs the following steps: identify the skeletal nodes of the human body in the image, and calculate the coordinate information of each skeletal node; and orientation signals are input into the deep learning network, and the deep learning network outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com