Anti-falling hydraulic lifting mechanism and device

A hydraulic lifting and anti-falling technology, applied in the field of hydraulic lifting, can solve the problems of bolt personal safety and property loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

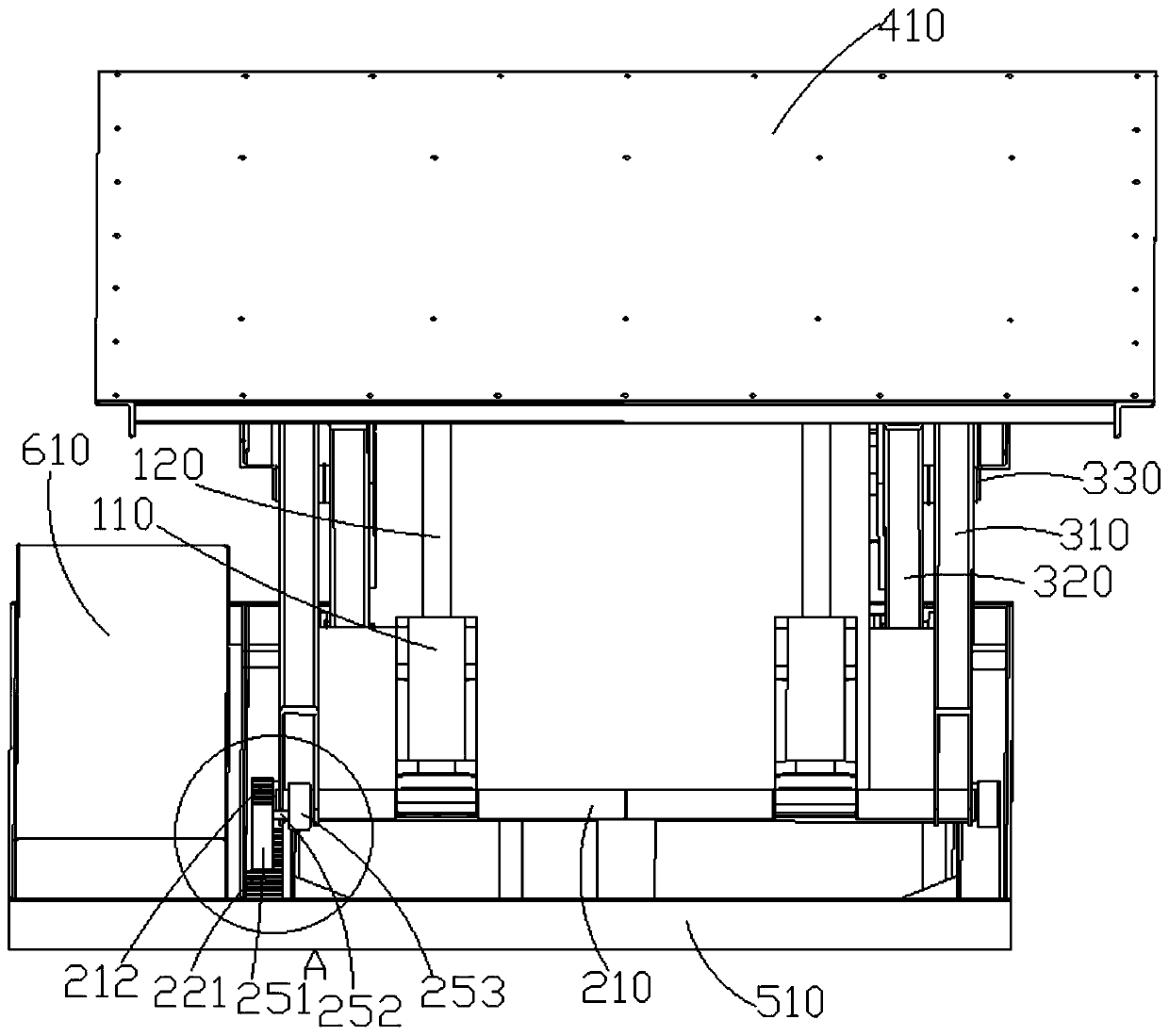

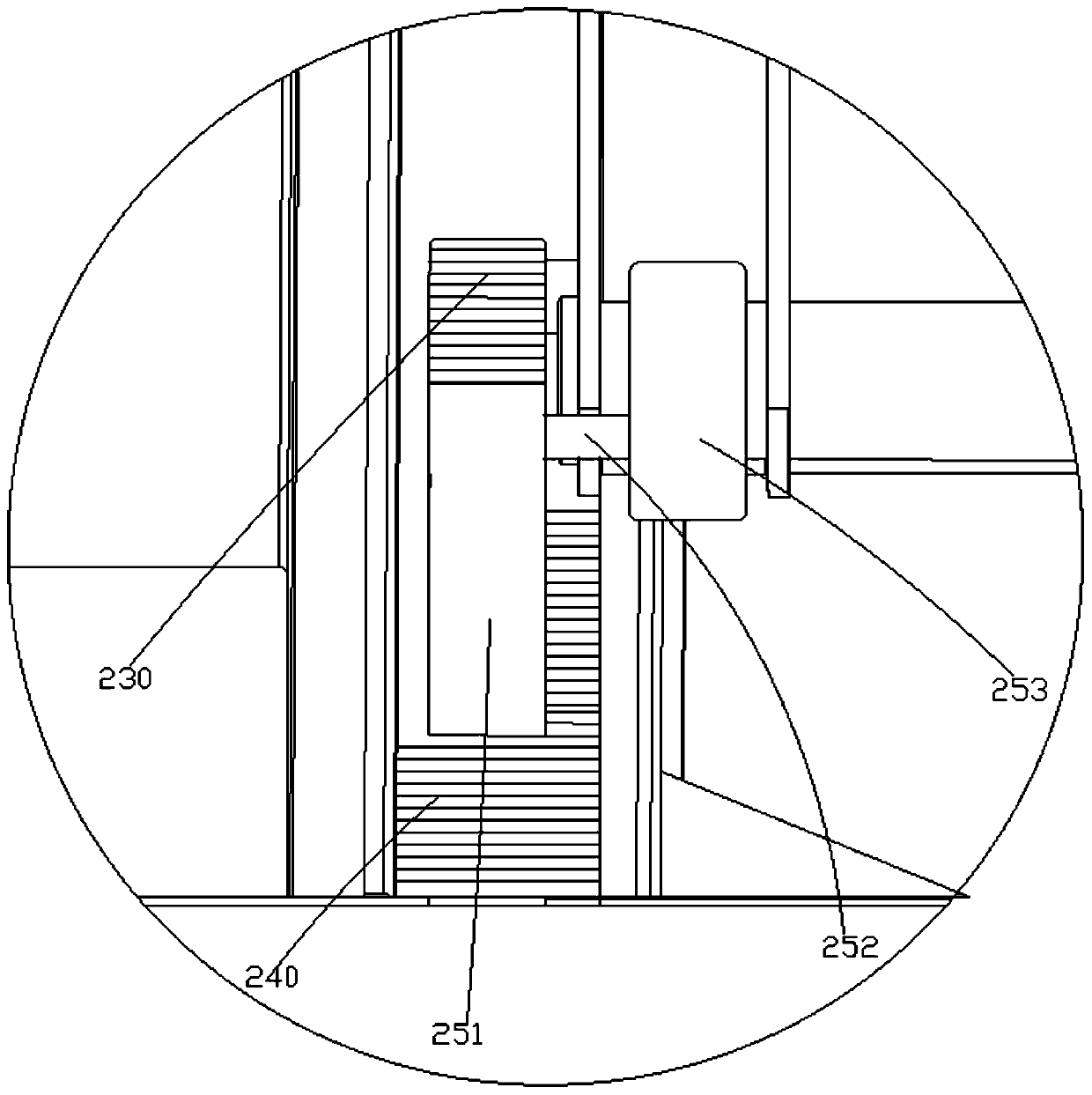

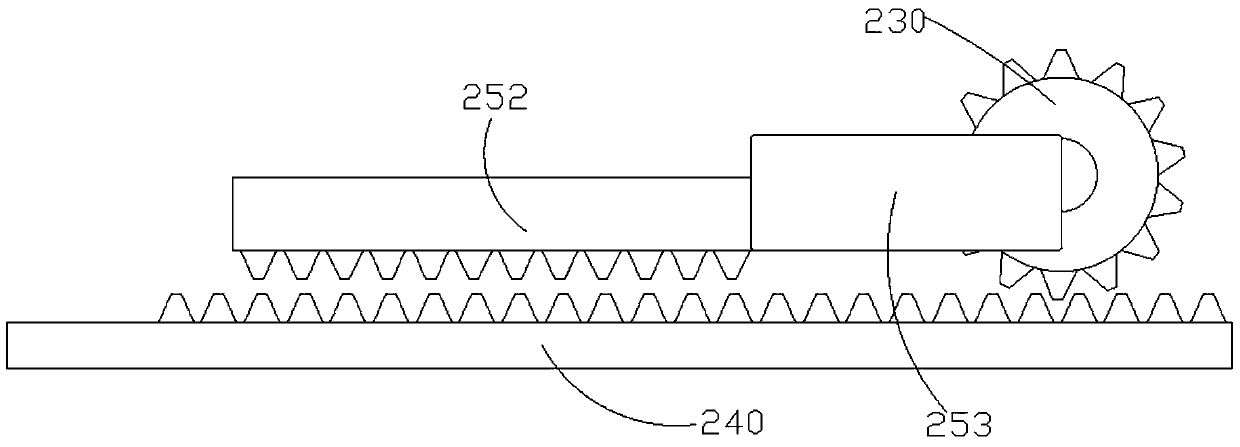

[0035] A kind of anti-drop hydraulic lifting mechanism, such as Figure 1-6As shown, it includes an oil cylinder, a control assembly, a lifting assembly, a first roller 210, a fixing assembly and a first track assembly; wherein, the lifting assembly is connected to one end of the first roller 210, and the lifting assembly is around the The first roller 210 rotates; the oil cylinder includes a piston rod 120 and a cylinder 110, the cylinder 110 is fixedly connected to the first roller 210, and the piston rod 120 moves relative to the cylinder 110, the The cylinder 110 drives the first roller 210 to move along the first track assembly, and the first rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com