Semi-circular tube plate forged piece forming method capable of improving utilization rate of blank

A semi-circular tube and utilization rate technology, which is applied in the field of metal forging forming, can solve the problem of low utilization rate of blanks, achieve the effect of saving blanks, reducing volume, and improving blank utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0019] Referring to the accompanying drawings, the specific implementation is as follows:

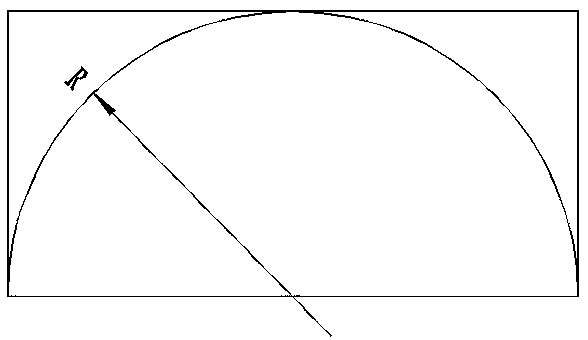

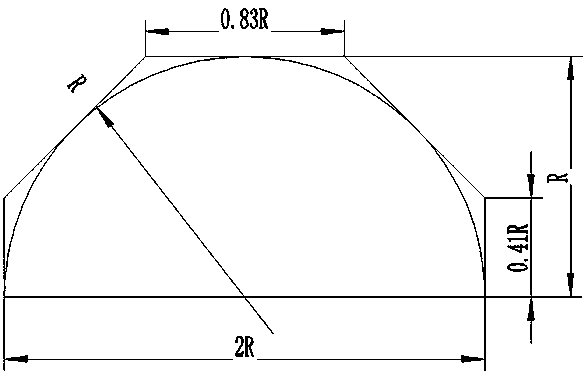

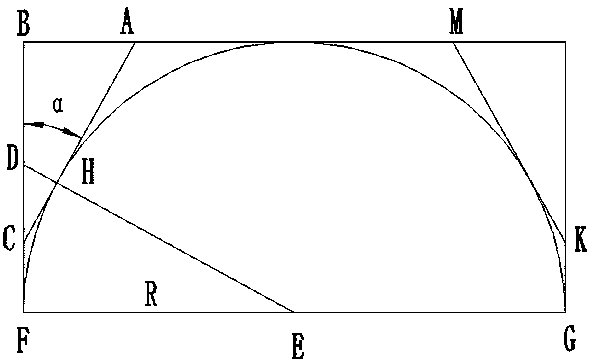

[0020] A method for forming a semicircular tube plate forging that can improve the utilization rate of blanks. The semicircular tube plate forging is a flat plate of equal thickness. The two parallel sides of the flat plate of equal thickness are semicircular sides with the same size and arranged symmetrically. Equal-length trapezoid-cuboid composite blanks, such as Figure 4 As shown, the isosceles trapezoid-rectangular composite blank is composed of two isosceles trapezoids and a rectangle with the same length, the width of the small end of the isosceles trapezoid is equal to the thickness of the semicircular tube plate forging, and the The width of the large end is equal to the width of the rectangular body, and the plane of the large end of the isosceles trapezoid is aligned with the equal width plane on the corresponding side of the rectangular body, so that the two ends of the iso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com