A floating connection guide, a floating connection assembly, a plug, and a socket

A floating connection and guide technology, which is applied to the parts, connections, and two-part connection devices of the connection device, etc., can solve the problems of lack of guidance function, hidden danger of direct blind insertion, and enlarged equipment space, etc., so as to achieve a small footprint , reduced size, small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052]The embodiments of the present invention will be further described below in conjunction with the drawings.

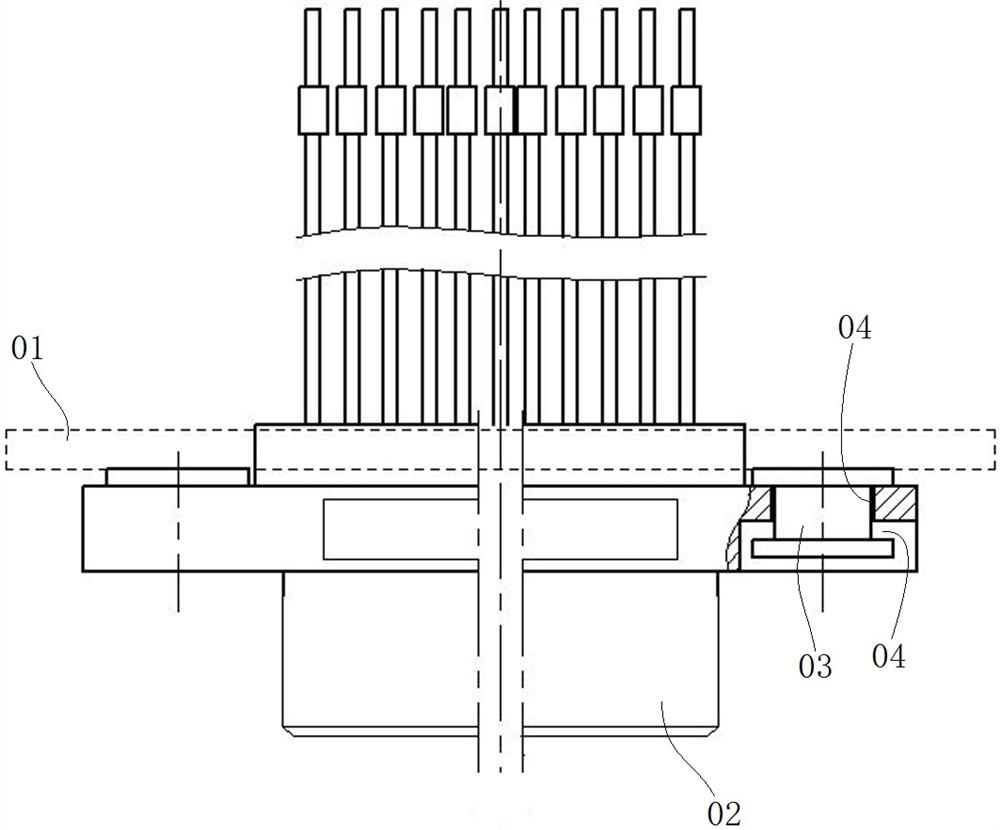

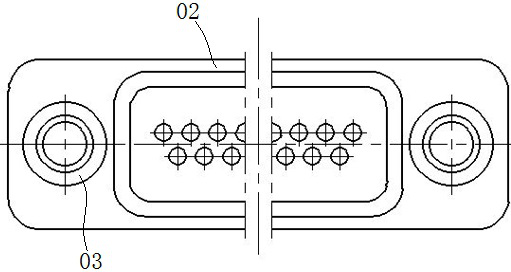

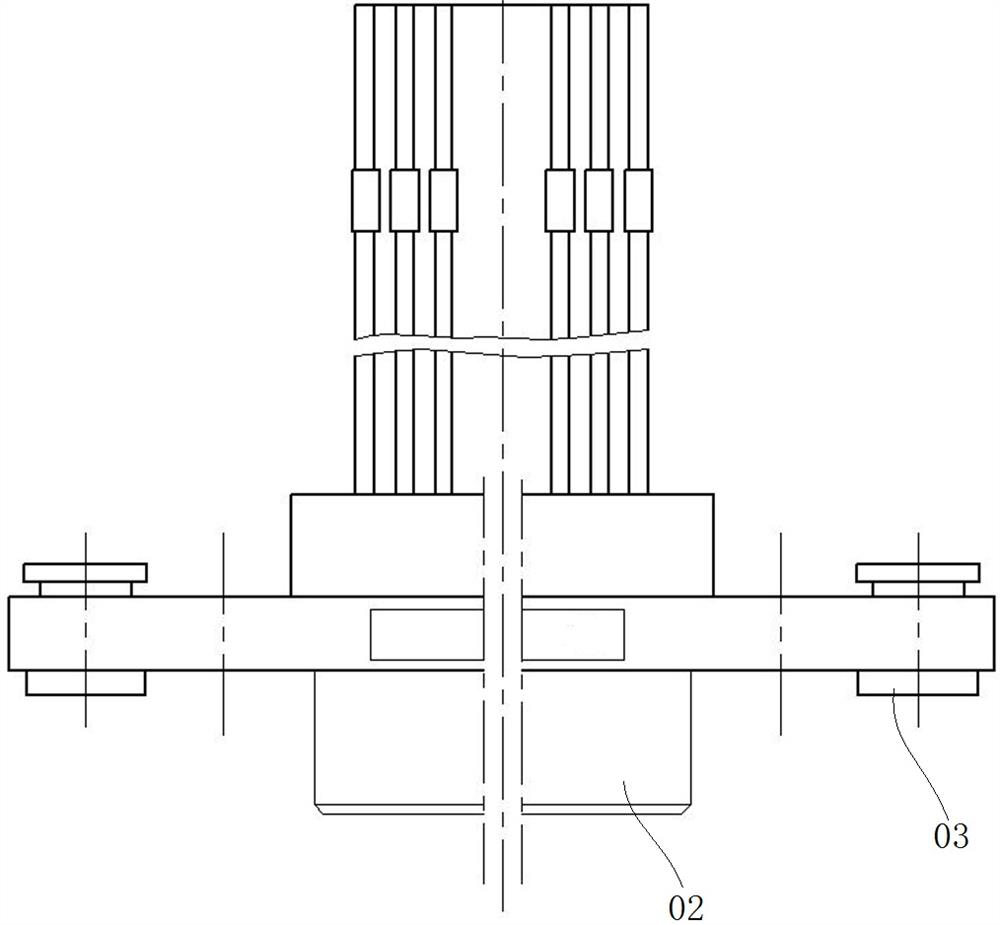

[0053]Specific embodiments of the socket of the present invention, such asFigure 5-7withPicture 10 As shown, the socket includes a housing. The housing has a housing flange 21. The housing flange 21 is provided with a connecting hole 211. The connecting hole 211 is a stepped hole. 1 Floating installation of the floating connection assembly, the floating connection assembly includes a floating connection guide 3 and a locking assembly, the floating connection guide 3 includes a radially convex stop 31 at one end, and a detachable connection with the locking assembly at the other end Connecting column, the housing flange 21 can float axially between the stop portion 31 and the locking assembly, and there is a gap between the hole wall of the connecting hole 211 and the connecting column so that the housing flange 21 can be connected relative to The column floats radially, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com