Heat exchange system, control method of heat exchange system and air conditioner

A technology of a heat exchange system and a control method, which is applied in the field of air conditioners, heat exchange systems and their control, and can solve the problem that the instability of hot gas bypass affects the stability of cooling capacity adjustment, the overall energy consumption has not been fully reduced, and the lack of variable Capacity compressor control coordination and other issues to achieve the effect of improving reliability and operating life, stable cooling/heating process, and stable temperature regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] refer to figure 1 , the present invention provides a control method of a heat exchange system, the heat exchange system includes a compressor and an electronic expansion valve, the control method includes the following steps:

[0066] The heat exchange system starts to run, A. The user inputs the set temperature;

[0067] B. Calculate the cooling capacity K% according to the set temperature and the measured temperature;

[0068] C. Adjust the actual opening of the electronic expansion valve to K% with the set maximum opening limit of the electronic expansion valve as 100%.

[0069] Using the above scheme, the opening of the electronic expansion valve is directly adjusted according to the cooling percentage, so that the adjustment of the cooling capacity is more accurate and timely, and the cooperation between the electronic expansion valve and the compressor is realized to make the refrigeration process more stable. The method of calculating the cooling capacity is se...

Embodiment 2

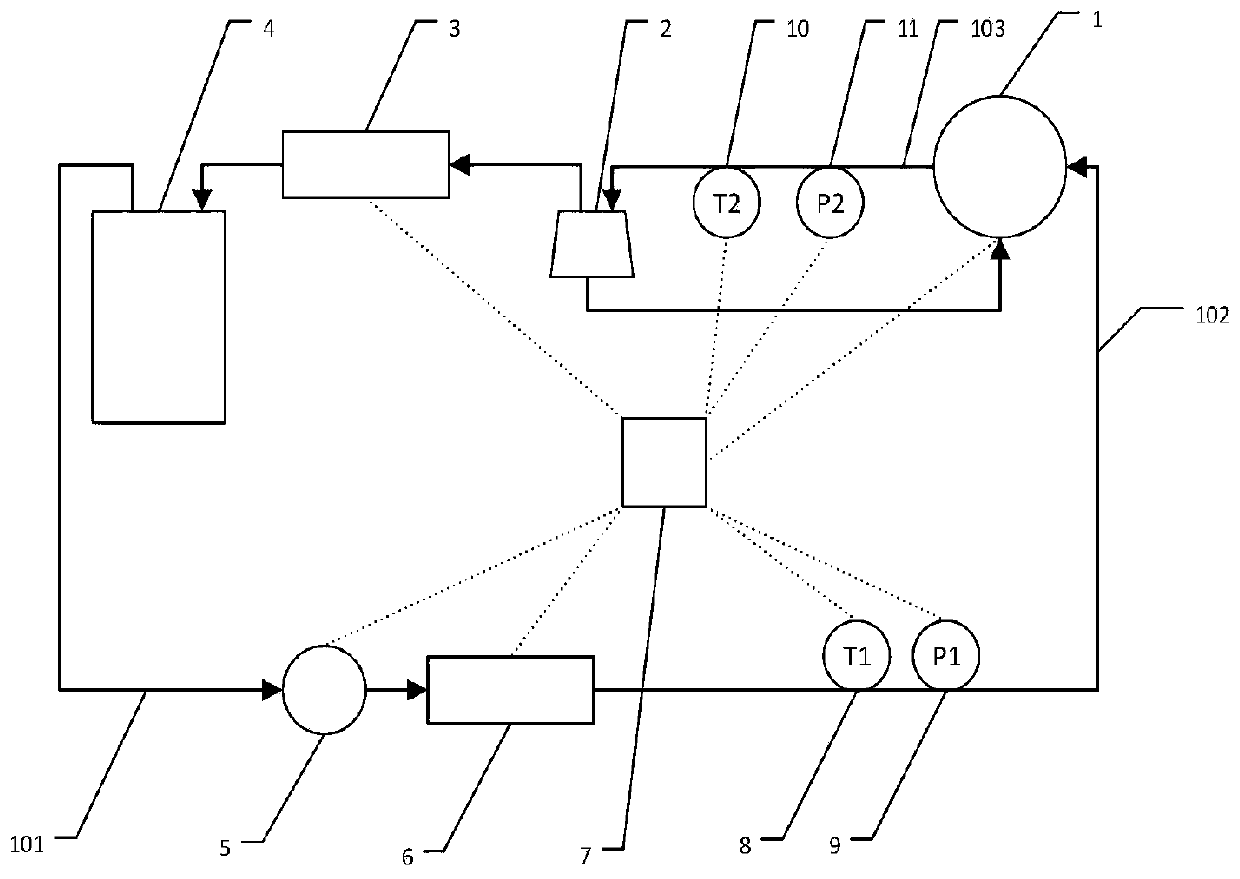

[0095] refer to figure 2, the present invention provides a heat exchange system, including a compressor 1, a condenser 3, a liquid receiver 4, an electronic expansion valve 5, and an evaporator 6 connected in sequence by a pipeline 101, and the heat exchange system also includes an electronic controller 7. The first temperature sensor 8 and the first pressure sensor 9 also include an early warning sensor arranged on the exhaust pipe 103; the first temperature sensor 8 and the first pressure sensor 9 are respectively used to measure the suction pressure of the compressor 1 The pressure and temperature of the gas pipeline 102, the early warning device is used to measure the abnormal signal of the compressor 1 exhaust pipeline 103; the compressor 1, the electronic expansion valve 5, the evaporator 6, the first temperature sensor 8, the first pressure sensor 9. The early warning device is electrically connected to the electronic controller 7, and the compressor 1 and the electron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com