A Small Diffusion Burner with Separate Preheating

A diffusion combustion and burner technology, which is applied to burners, gas fuel burners, combustion types, etc., can solve the problems of poor flame stability, prone to tempering, and low combustion efficiency, and achieves higher preheating temperature and higher mixing. effect, the effect of high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

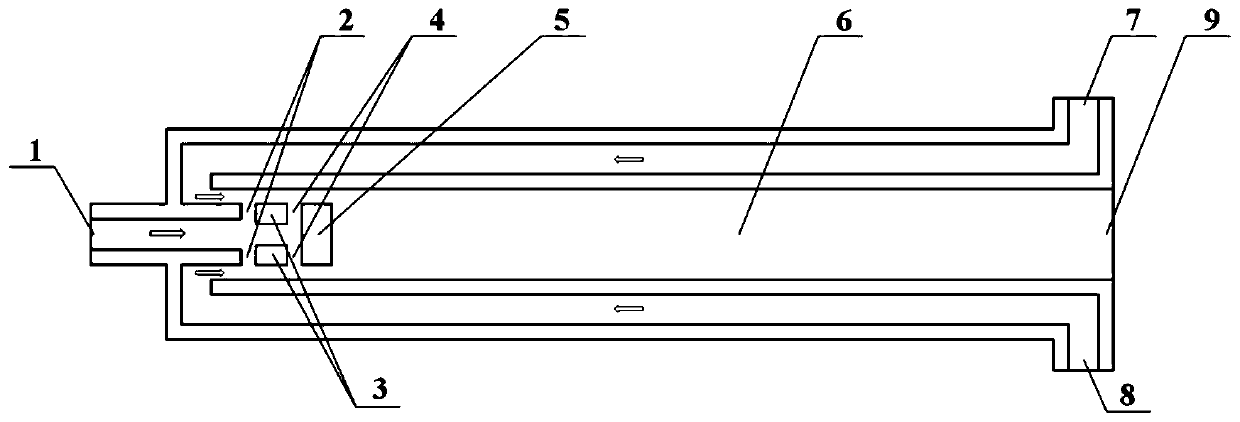

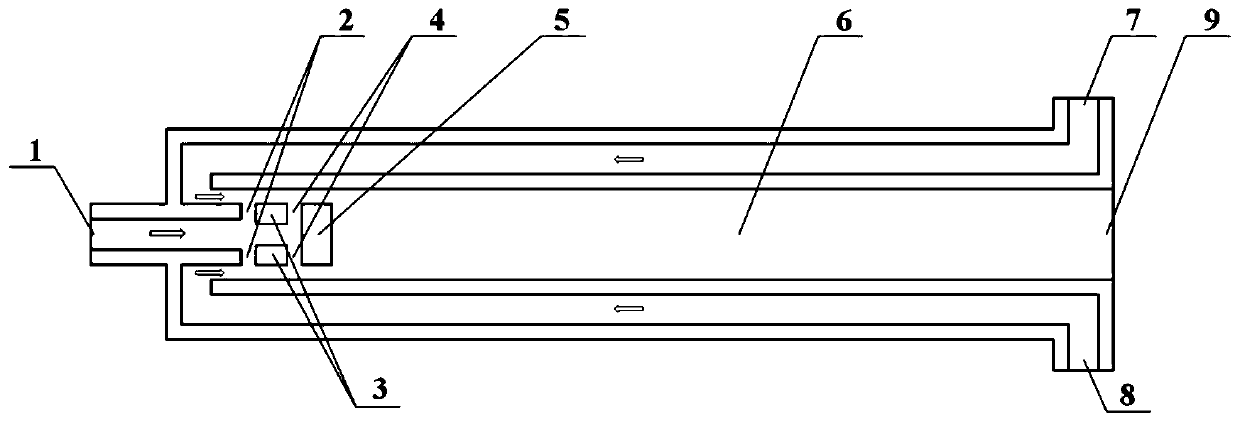

example 1

[0040] The inlet width of the fuel channel is 3mm, and the inlet width of the two J-shaped oxidant preheating channels is 3mm. The cross-sectional area of the fuel passage is smaller than that of the combustion chamber, and the distance between the fuel passage and the wall of the combustion chamber is 1mm. The length and width of the two rectangular splitter plates are 2mm and 1.5mm respectively, the distance between the two splitter plates is 2mm, and the length and width of the rectangular baffles are 2mm and 5mm respectively. The distance between the first outlet and the second outlet is 1mm. The length and width of the combustion chamber are 50mm and 7mm, respectively. The manifold block surface is not coated with platinum catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com