Brake locking device and method of use of beam pumping unit

A beam pumping unit and lock-stop technology, which is applied in earthwork drilling, mechanical equipment, wellbore/well components, etc., can solve the problems of operator safety hazards, unstable use, brake failure, etc., and achieve the braking effect Good, the overall structure is closely connected, and the brake lock effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

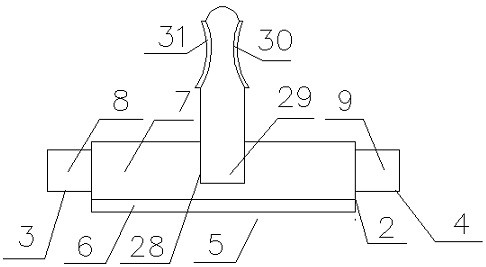

[0020] A beam pumping unit brake locking device, which consists of: a reducer, the reducer has an outer shell 1, the outer shell has a slanted inlaid groove 2, a slanted inlaid groove of the described One side is connected to the upper chute 3, and the other side is connected to the lower chute 4. The bottom of the first half of the inclined inlaid groove is connected to the groove 5. The height of the groove is lower than that of the inclined inlaid groove. The groove is bonded with a flat magnetic Plate 6, the second half of the inclined mosaic groove is equipped with a sliding magnetic plate 7, the flat magnetic plate does not affect the sliding of the sliding magnetic plate, and can play the role of suction and fixing, the sliding magnetic plate is connected to the upper plug Plate 8, the upper board is inserted into the upper chute and slides, the upper board ensures that the sliding magnetic board will not break away from the inclined inlay groove when it is loaded and sl...

Embodiment 2

[0022] In the brake locking device of a beam pumping unit described in Embodiment 1, the output shaft is connected to the crank 15 of the beam pumping unit, and the crank rotates around the output shaft. The inner lower part of the crank is provided with a flat inlaid groove 16, and the flat inlaid groove is welded with a brake iron plate 17. The brake iron plate does not protrude from the surface of the crank, and the brake iron plate does not protrude from the surface of the crank. Affect the normal use of the crank. When braking is required, the brake iron plate can fix (brake) the crank to ensure that the crank does not continue to rotate. When braking is required, the sliding magnetic plate is pushed forward and inserted into the outer shell Between the crank, the brake iron plate is attracted and fixed, and the sliding magnetic plate absorbs the brake iron plate to play the role of a heavy brake.

Embodiment 3

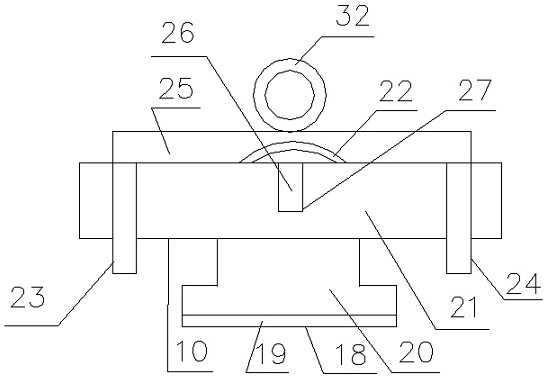

[0024] A brake and lock device for a beam pumping unit described in Embodiment 1, the bottom of the brake groove is connected to the inverted T-shaped chute 18, and the bottom of the inverted T-shaped chute is bonded to the bottom magnetic plate 19 , the inverted T-shaped iron slider 20 is housed in the inverted T-shaped chute, the top of the inverted T-shaped iron slider is connected to the brake skateboard 21, and the inverted T-shaped iron slider can be placed in the inverted T-shaped chute Sliding, when the brake is not needed, the brake skateboard is located in the second half of the inverted T-shaped chute, without hindering the normal operation of the crank. The brake socket further functions as a brake to ensure that the crank is not in operation (action). The tail end of the brake skateboard is fixedly connected to the handle 22, and the handle is located at the tail end of the brake skateboard, so that it does not affect the crank when not braking. In normal use, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com