Power equipment defect management method, system and terminal based on AHP and remote support

A technology for power equipment and defect management, applied in data processing applications, instruments, calculations, etc., can solve the problems of being unable to rush to the scene in time, missed testing, and difficulty in effectively discovering latent defects of equipment, so as to improve diagnostic efficiency and accuracy, Guarantee the effect of safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

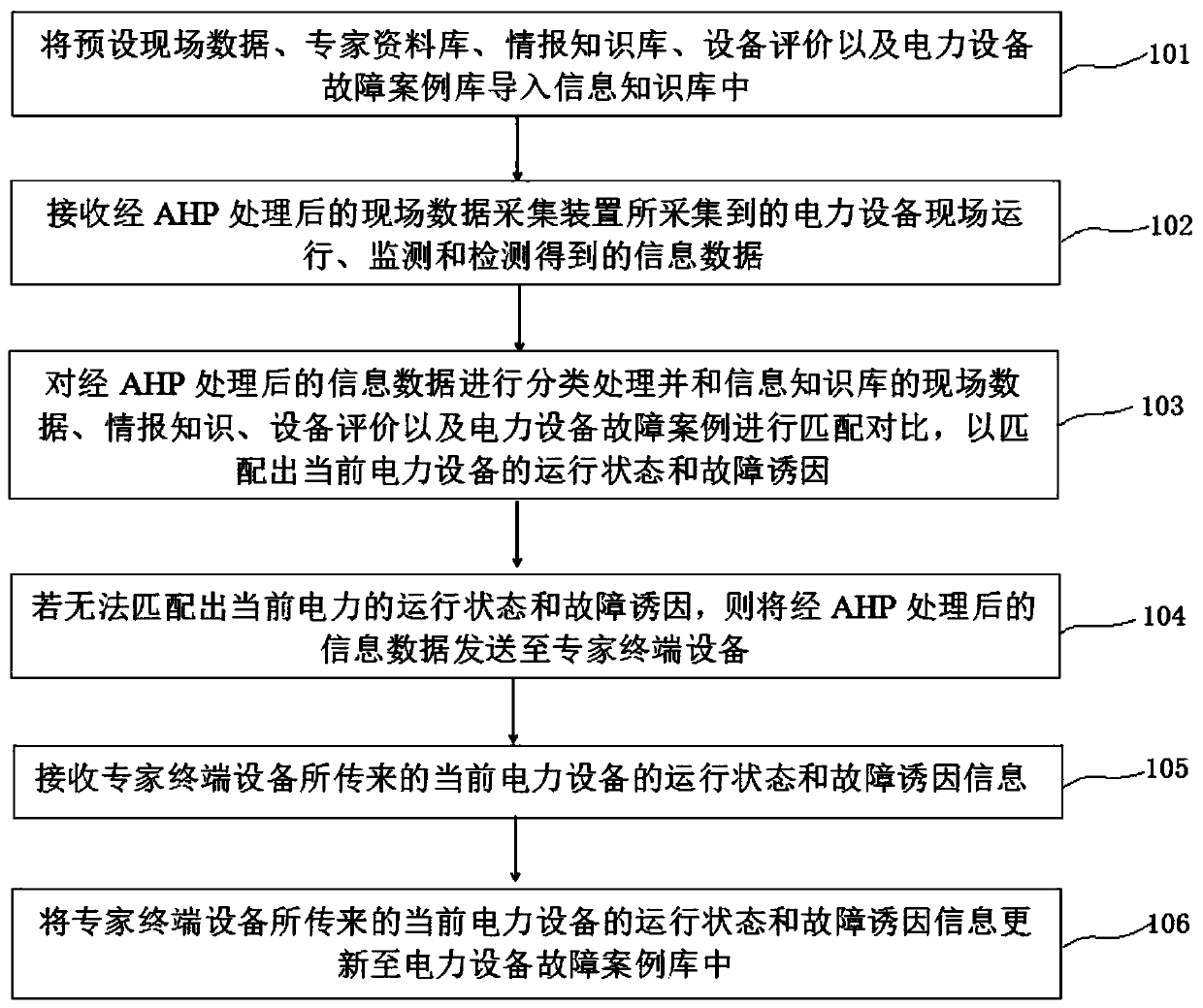

[0023] refer to figure 1 As shown, the defect management method for electrical equipment based on AHP and remote support provided by this embodiment mainly includes the following steps:

[0024] 101. Import preset field data, expert database, intelligence knowledge base, equipment evaluation and power equipment fault case database into the information knowledge base.

[0025] 102. Receive the information data collected by the on-site data acquisition device processed by AHP from the on-site operation, monitoring and detection of power equipment; after AHP (Analytic Hierarchy Process) processing, it can be determined whether the collected data is useful.

[0026] 103. Classify and process the information data processed by AHP and match and compare with the field data, intelligence knowledge, equipment evaluation and power equipment failure cases of the information knowledge base to match the current operating status and failure causes of the power equipment, so as to It can qu...

Embodiment 2

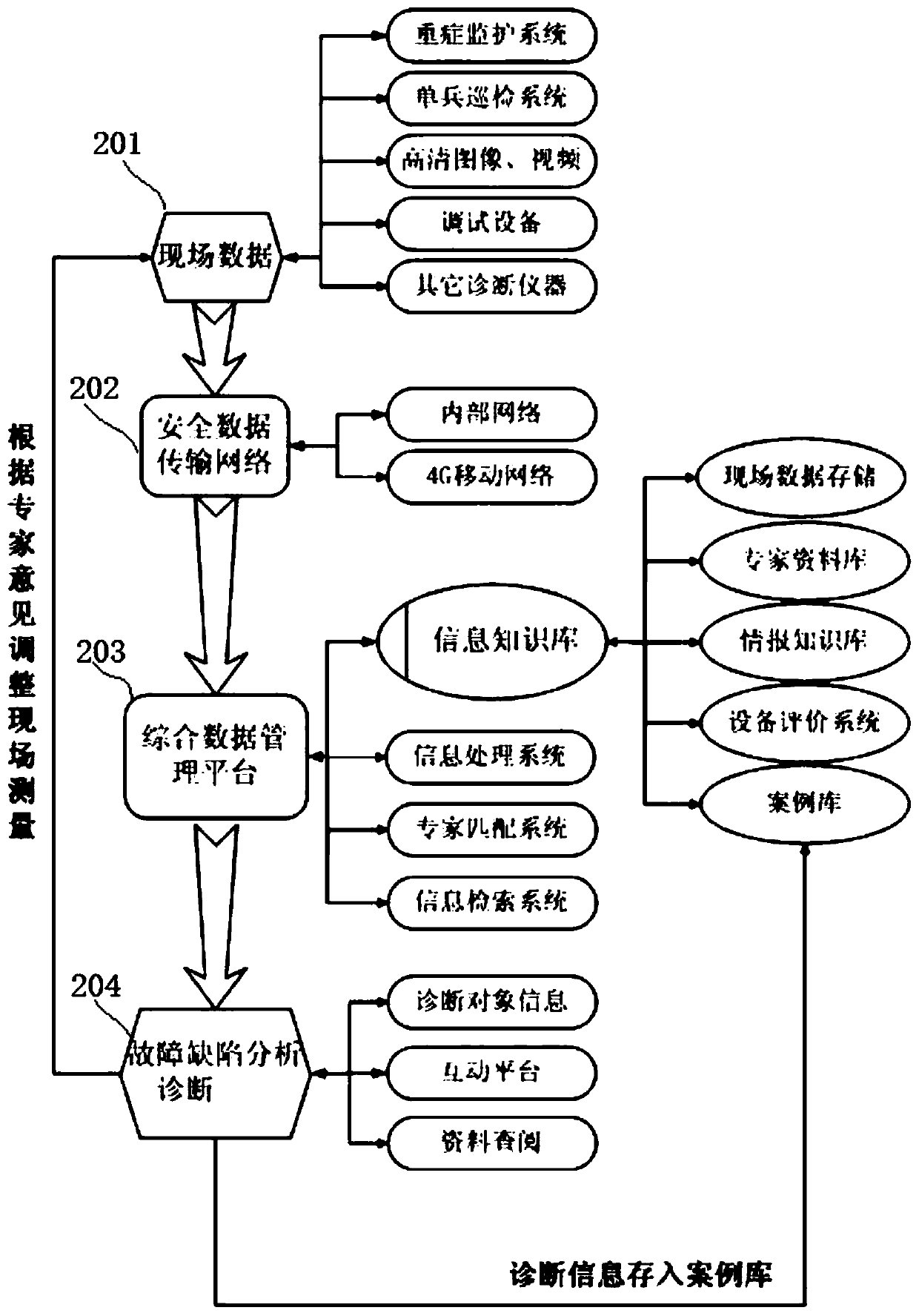

[0034] refer to figure 2 As shown, it is a schematic diagram of the composition of the AHP and remote support-based power equipment defect management system provided by this embodiment, including:

[0035] The on-site data acquisition device 201 is used to collect the information data obtained from the on-site operation, monitoring and detection of electric power equipment, and transmit the data to the comprehensive data management platform after being processed by AHP;

[0036] The integrated data management platform 202 is used for data storage and management, and has diversified data storage and management functions, including an information processing system, an expert matching system, an information retrieval system, and an information knowledge base; The incoming information data is compared and analyzed with the information knowledge base to analyze the current operating status and failure causes of the power equipment; the information knowledge base includes on-site d...

Embodiment 3

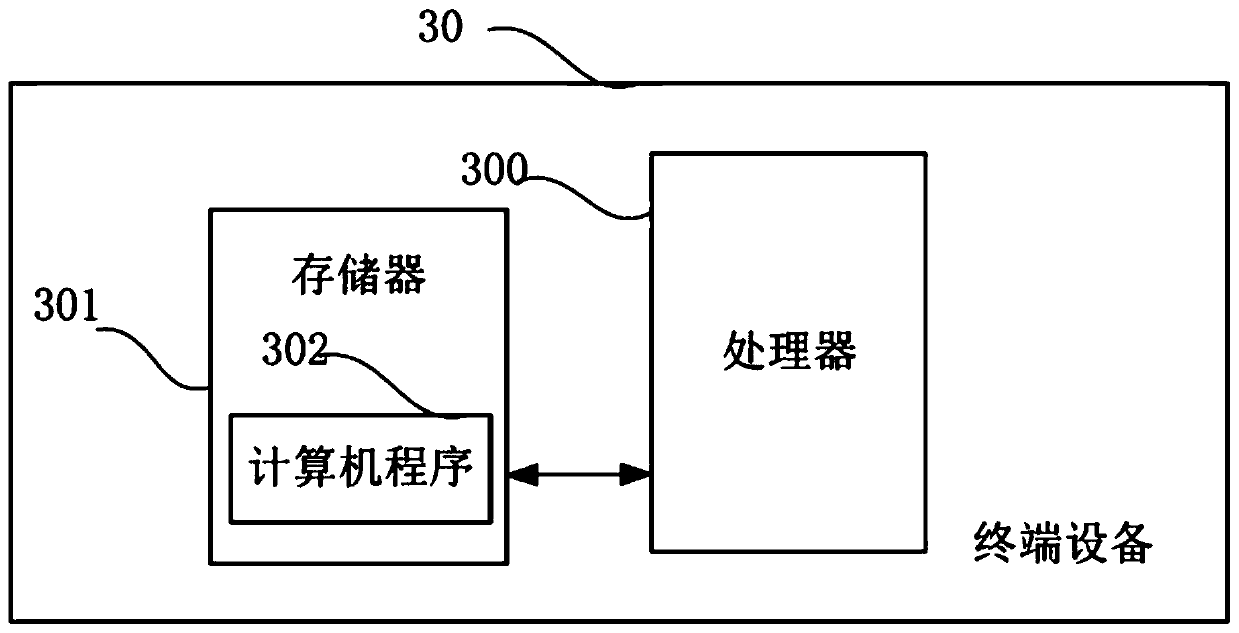

[0043] image 3 It is a schematic diagram of a power equipment defect management terminal provided by an embodiment of the present invention. Such as image 3 As shown, the electrical equipment defect management terminal 30 of this embodiment includes: a processor 300, a memory 301, and a computer program 302 stored in the memory 301 and operable on the processor 300, such as avoiding power equipment defect management program. When the processor 300 executes the computer program 302, the steps in the first embodiment above are implemented, for example figure 1 Steps 101 to 106 are shown.

[0044] Exemplarily, the computer program 302 can be divided into one or more modules, and the one or more modules are stored in the memory 301 and executed by the processor 300 to complete the present invention. The one or more modules may be a series of computer program instruction segments capable of completing specific functions, and the instruction segments are used to describe the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com