Pathological slide replacement device

A glass slide and pathology technology, applied in the field of biomedical instrument design and automatic slide changer, can solve the problems of long time for slide change, increase mechanical damage, reduce system stability, etc., and achieve fast speed, simple operation and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

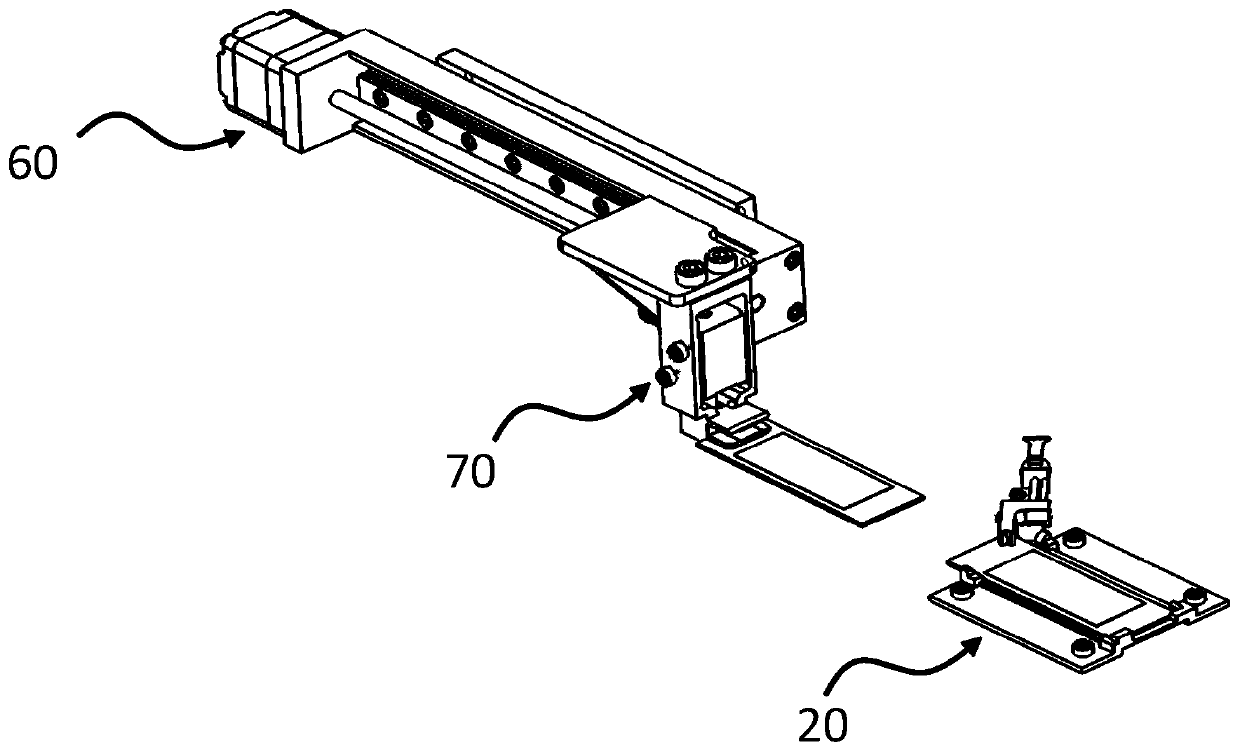

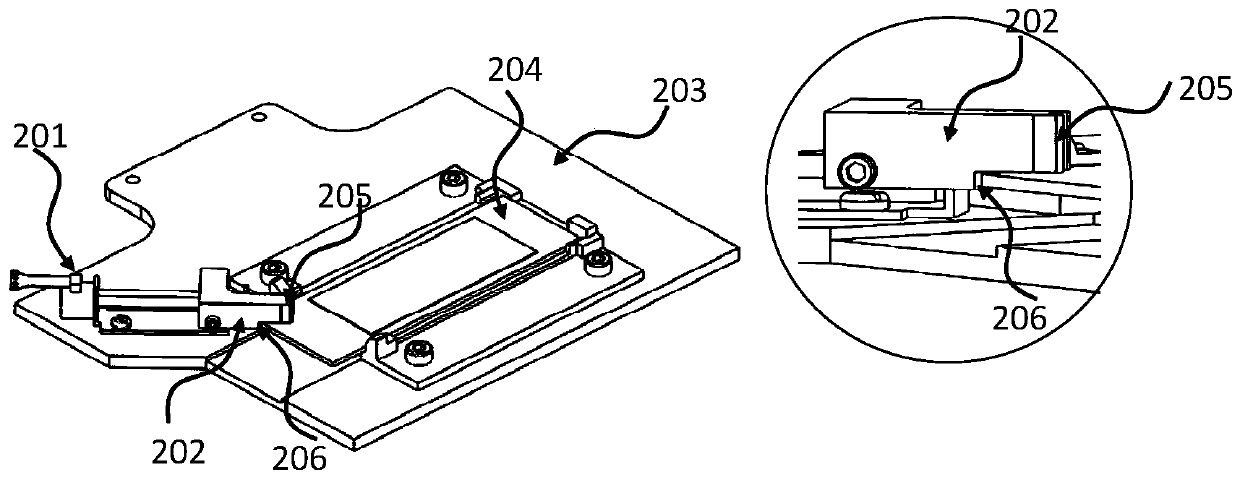

[0031] See figure 1 , this embodiment includes a feed drive mechanism 60 , a double-clamp slide holder 70 and a slide holder 20 .

[0032] The feed drive mechanism 60 is used to fix the double-clamping slide holder 70 and drive the double-clamping slide holder 70 to move relative to the slide holder 20;

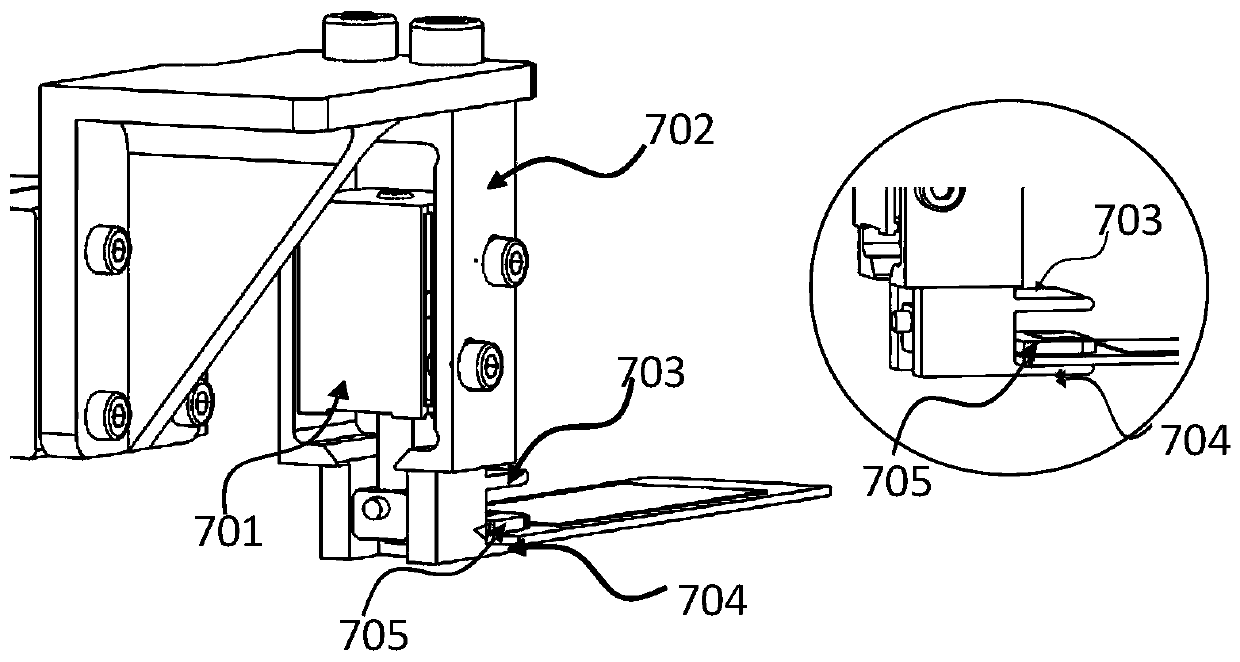

[0033] In this example, see figure 2 , double-clamp slide clamp 70, used for clamping and transporting slides, including a longitudinal displacement mechanism 701, a clamp base 702 and a movable clamping piece 705; one side of the clamp base 702 is provided with an upper clamping plate 703 and a lower Clamping plate 704; the longitudinal movement mechanism 701 is fixed on the clamp base 702, and one end of the longitudinal movement mechanism 701 is provided with a movable clamping piece 705, and the movable clamping piece 705 is positioned between the upper clamping plate 703 and the lower clamping plate 704. The vertical up and down movement of the displacement mechanism ...

Embodiment 2

[0047] See Figure 4 On the basis of Embodiment 1, the present invention further adds a lifting mechanism 50, and the driving mechanism 60 and the double-clamping slide clamp 70 are installed on the lifting mechanism together to drive the feed driving mechanism 60 and the double-clamping mechanism. The holding type slide holder 70 moves longitudinally, so the height of the double holding type slide holder 70 can be flexibly adjusted to suit the height of the slide storage box or the slide holder 20

[0048] The lifting mechanism 50 is composed of a stepping motor screw mandrel slide table in this example. When the stepping motor is fed, the stepping motor drives the screw mandrel to rotate and drives the slide table to move longitudinally.

Embodiment 3

[0050] See Figure 5 On the basis of Example 2, a rotating mechanism 10 is further added, and the rotating mechanism 10 is installed at the bottom of the lifting mechanism for driving the feed drive mechanism 60 and the double-clamping slide holder 70 to rotate in a plane. In practical applications, the slide storage box and the slide holder 20 are probably not in the same orientation, so through the flexible rotation of the rotating mechanism, the double-clamping slide holder 70 can be aligned with the slide storage box when taking the slide, When sending the slides, the double clamping slide holder 70 rotates an angle to align with the slide holder 20 .

[0051] In this example, the rotating mechanism 10 is composed of a stepping motor and a worm gear structure. When the stepping motor is fed, the rotation of the stepping motor drives the worm gear structure to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com