Waste incineration system

A waste incineration and rotating shaft technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of resource waste and low efficiency, and achieve the effect of simplifying equipment structure and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

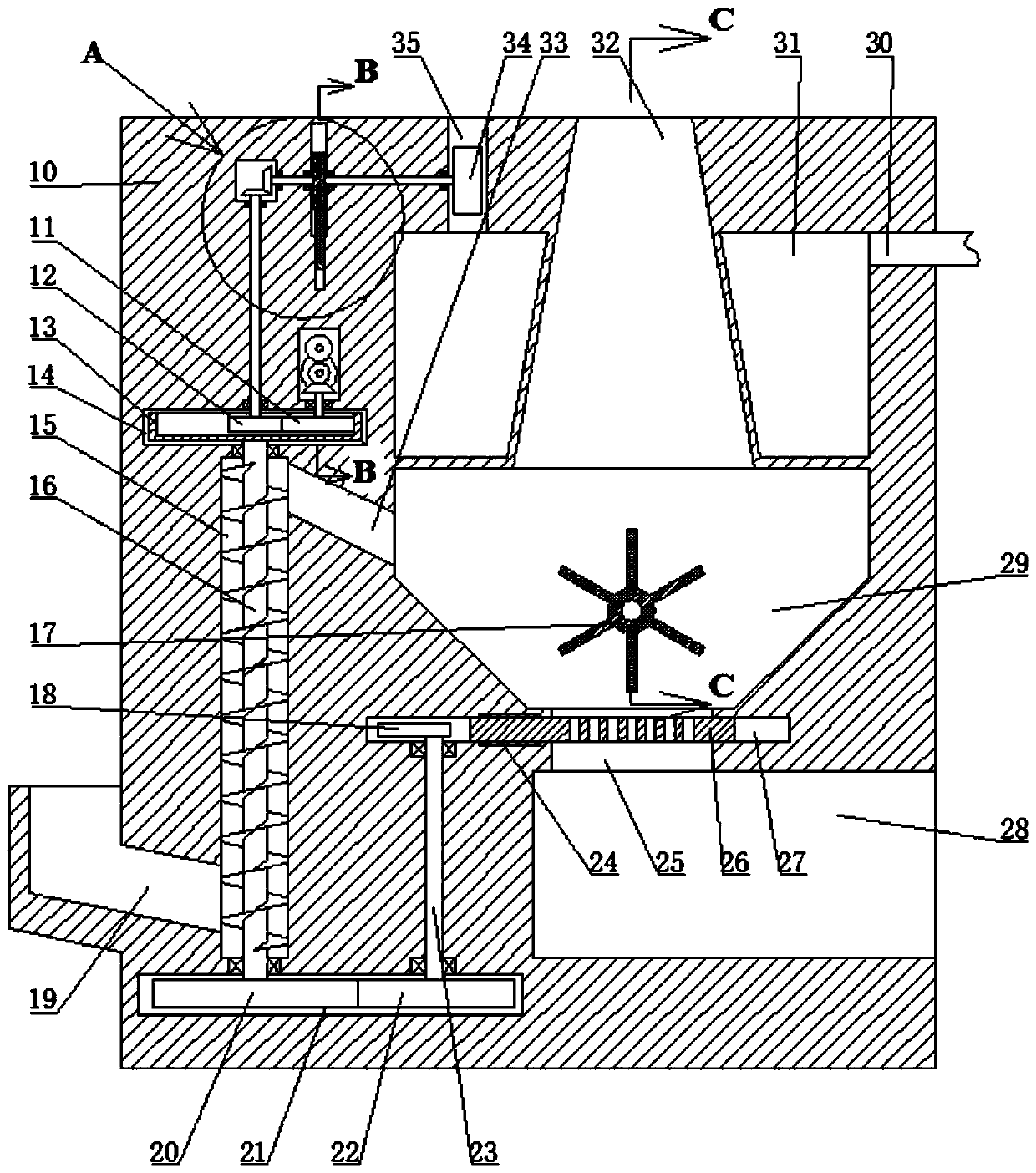

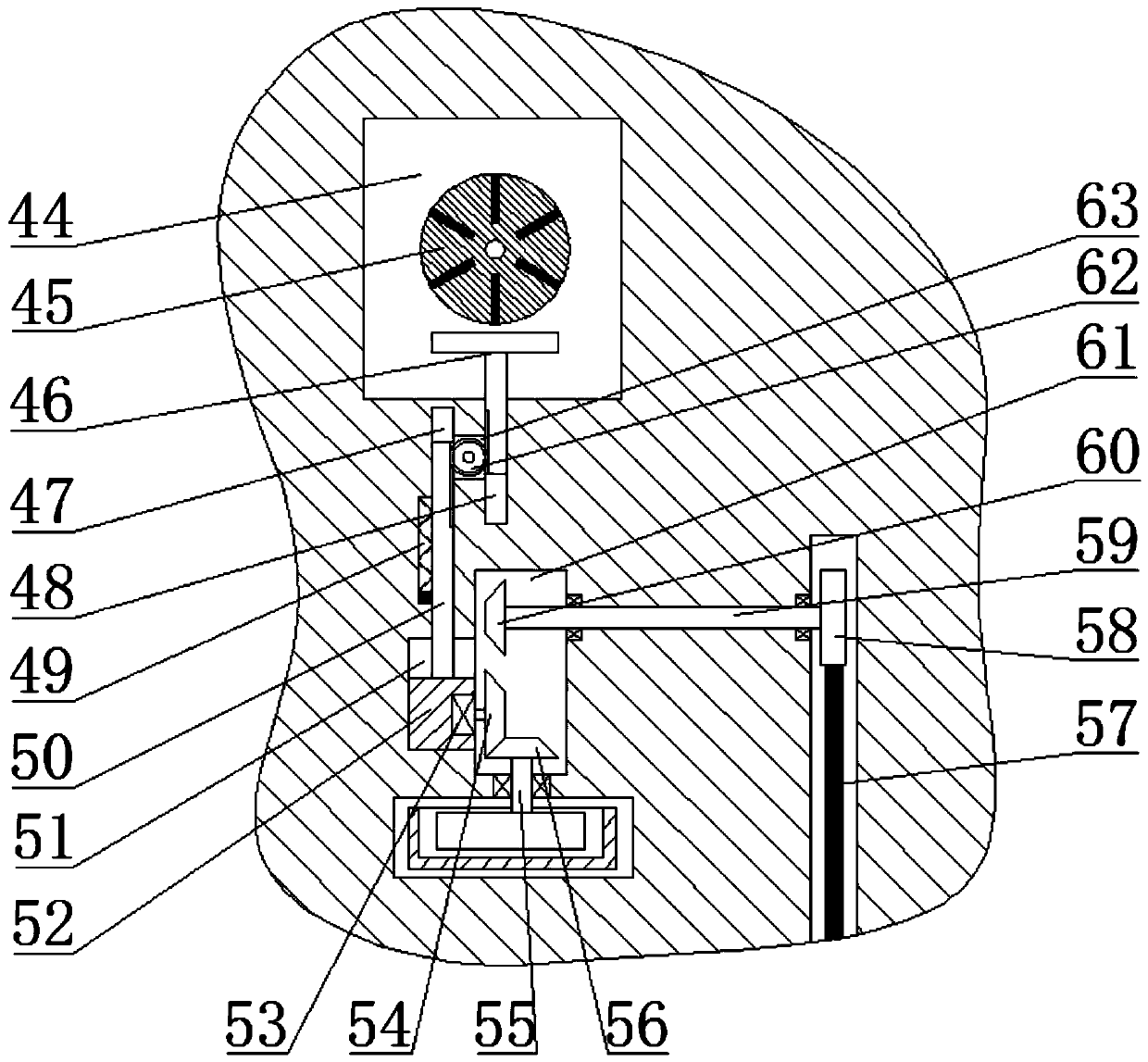

[0014] Combine below Figure 1-4 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0015] Such as Figure 1-4 As shown, a kind of waste incineration system of the present invention includes a fuselage 10, an incineration chamber 29 and a feeding chamber 15 arranged in the fuselage 10, a flue 32 is arranged in the top wall of the incineration chamber 29, and the A steam chamber 31 surrounds the circumferential wall of the flue 32, a water inlet 30 is provided in the right side wall of the steam chamber 31, an air outlet 35 is provided in the top wall of the steam chamber 31, and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com