Convenient and rapid angle channel

A keel and fast technology, applied in building components, buildings, ceilings, etc., can solve the problems of high labor intensity, low efficiency, unstable structure, etc., and achieve the effect of reduced labor intensity, stable fixed connection, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

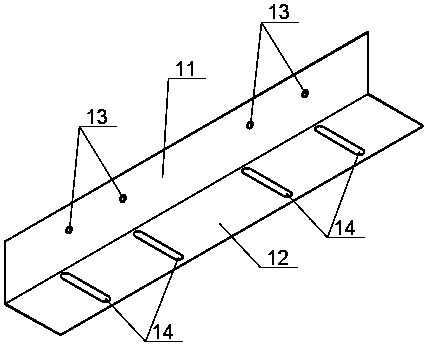

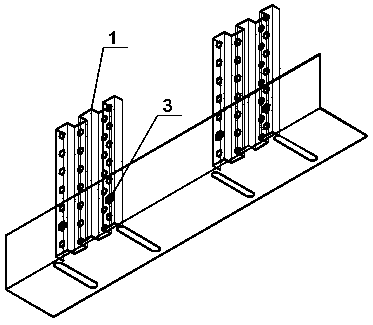

[0032] Example 1, such as figure 2 As shown, a fast fixed connection can be realized by using a blind rivet 3 to pass through the vertical keel 1 to connect the hole and the first through hole 13 .

Embodiment 2

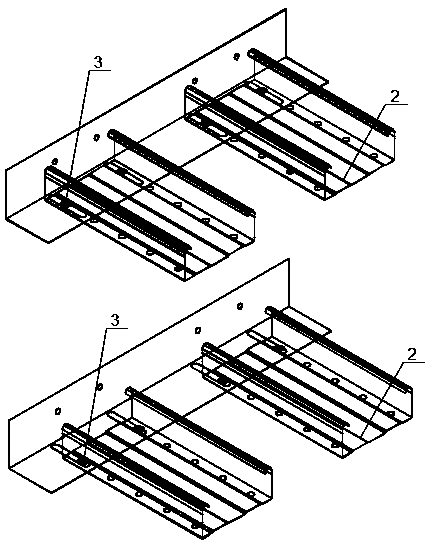

[0033] Example 2, such as image 3 As shown, by using the blind rivet 3 to pass through the connecting hole of the transverse keel 2 and the second through hole 14, a fast fixed connection can be realized. In actual construction, because the wall surface is not completely flat, there will be a certain drop. The second through hole 14 is The oblong hole is matched with the 2 connection holes of the transverse keel, which can realize width adjustment.

Embodiment 3

[0034] Example 3, such as Figure 4 As shown, by using the blind rivet 3 to pass through the connection hole of the vertical keel 1 and the first through hole 13 , and the connection hole of the horizontal keel 2 and the second through hole 14 , quick fixed connection can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com