Pay-off device for power construction

A pay-off device and electric power construction technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problem that the cable pay-off device cannot be crossed, etc., and achieves remarkable applicability and smooth pay-off process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

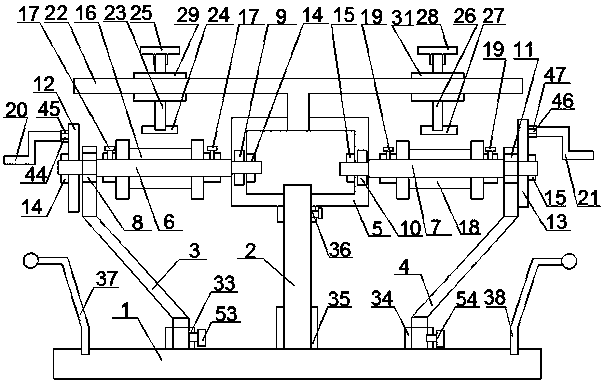

[0037] Such as figure 1 As shown, a wire-releasing device for electric power construction includes a base 1 and a wire-releasing module arranged on the base;

[0038]The pay-off module includes a connecting shaft 2 arranged on the base 1, a first support rod 3 arranged on the base 1 and on the left side of the connecting shaft 2, a second support rod 3 arranged on the base 1 and on the right side of the connecting shaft 2 Support rod 4, the shaft sleeve 5 that is arranged on the upper end of the connecting shaft 2, the first shaft rod 6 that is arranged between the left side of the shaft sleeve 5 and the upper end of the first support rod 3, is arranged on the right side of the shaft sleeve 5 and the second The second shaft 7 between the upper ends of the support rods 4, the first bearing 8 arranged at the connection between the left end of the first shaft 6 and the first support rod 3, and the first bearing 8 arranged at the right end of the first shaft 6 and connected with t...

Embodiment 2

[0069] Such as Image 6 As shown, the difference between the present embodiment and the first embodiment is that a transmission unit is further provided between the right end of the first shaft 6 and the left end of the second shaft 7 .

[0070] The transmission unit includes a transmission card 48 arranged between the right end of the first shaft 6 and the left end of the second shaft 7 , and a first fixed part arranged at the connection between the left end of the transmission card 48 and the first shaft 6 . The bolt 49 and the first fixing nut 50 , the second fixing bolt 51 and the second fixing nut 52 arranged at the joint between the right end of the transmission card 48 and the second shaft 7 .

[0071] The left end of the transmission card 48 is clamped with the right end of the first shaft 6, and the connection between the transmission card 48 and the first shaft 6 is fixed by the first fixing bolt 49 and the first fixing nut 50. The transmission card 48 The right end...

Embodiment 3

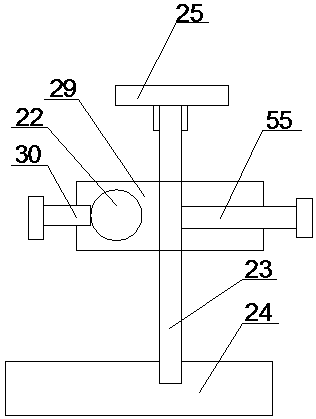

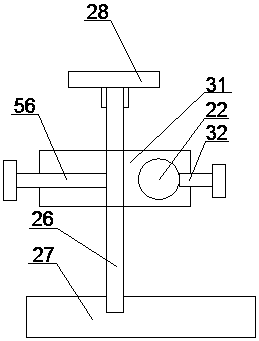

[0077] Such as Figure 7 , 8 As shown in . The position is fixed by the sixth limit bolt 57, and the length of the first limit plate 24 is equal to the width of the wire clamping groove of the first wire barrel 16;

[0078] The second limit column 26 is directly connected to the right end of the limit rod 22, and the connection between the second limit column 26 and the limit rod 22 is fixed by the seventh limit bolt 58. The second limit plate 27 The length is equal to the width of the clamping groove of the second wire cylinder 18.

[0079] When it is necessary to fix the unclamped cables, only the sixth limit bolt 57 and the seventh limit bolt 58 are loosened first, and the first limit column needs to be screwed down by means of the first handle 25 and the second handle 28 23. The second limit post 26, so that the first limit pressure plate 24 or the second limit pressure plate 27 can press the entire upper surface of the first line barrel 16 and the second line barrel 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com