Bactericidal odor-removing perfume and preparation method thereof

A technology for removing peculiar smell and perfume, which is applied in the formulation of perfume preparations, antibacterial drugs, antifungal agents, etc. It can solve the problems of endangering health and the lack of oak extract perfume, etc., and achieve a wide range of bactericidal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

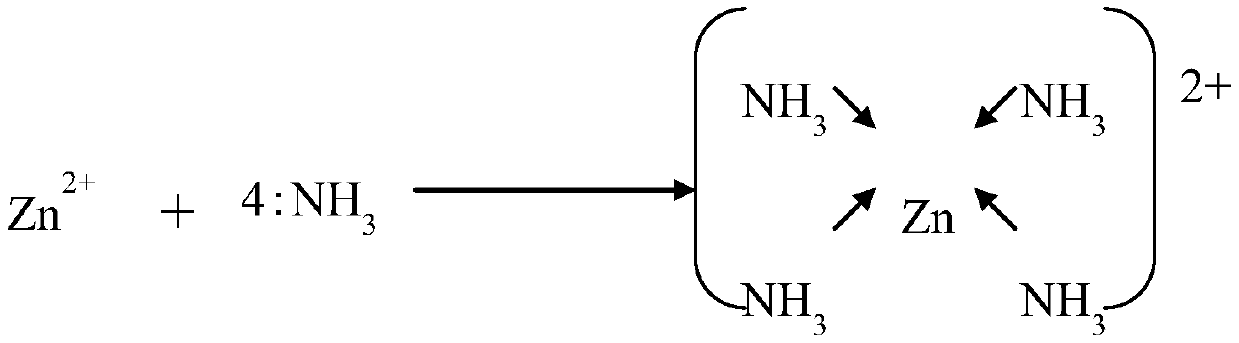

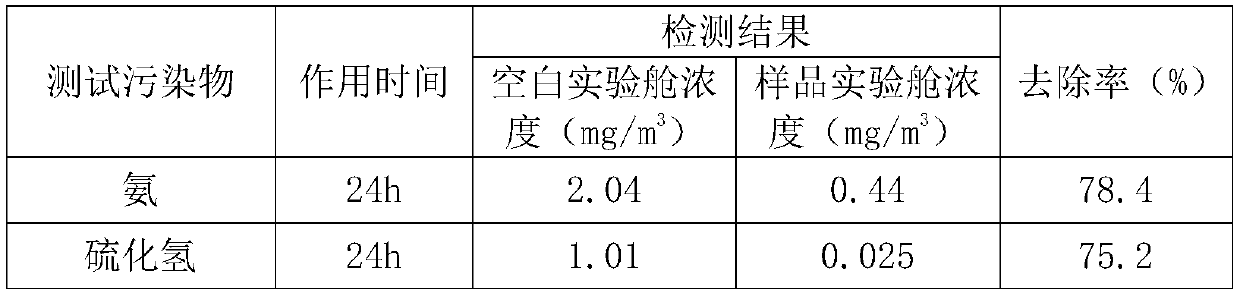

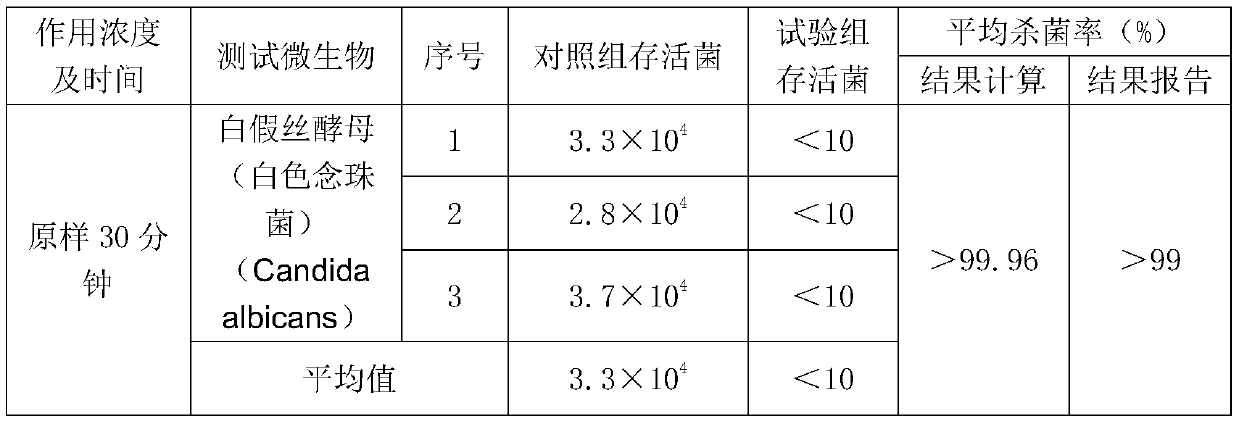

Method used

Image

Examples

Embodiment 1

[0033] The present invention is a kind of bactericidal and odor-removing perfume. Corn is the main raw material, which is 80% alcohol, 6% flavor, 2% deodorant, 2% bactericide, 2% isopropyl myristate, and 0.3% benzoin. , Oak extract 0.03%, the balance is deionized water.

[0034] The preparation method of sterilizing and removing odor perfume of the present invention includes the following steps:

[0035] 1) Pretreatment: ①Pretreatment of alcohol: Alcohol produced by fermentation and deodorization of corn as the main raw material, add appropriate amount of musk ketone, musk T, musk 105 for low temperature purification for more than 20 days, and the purified alcohol is sealed at 15°C Leave it for more than one month; ②Flavor pretreatment: add deodorant, fungicide, and fragrance retention agent to the fragrance and age for 1 month;

[0036] 2) Mixing: Put the pretreated alcohol produced by fermentation and deodorization with corn as the main raw material, and the pretreated essence, is...

Embodiment 2

[0040] A bactericidal and odor-removing perfume composed of the following mass percentages of raw materials: 75% alcohol, 10% flavor, 3% deodorant, 2% bactericide, and isopropyl myristate made from corn as the main raw material by fermentation and deodorization Ester 2%, benzoin 0.5%, oak extract 0.02%, the balance is deionized water.

[0041] The preparation method of the bactericidal and odor-removing perfume of Example 2 is the same as that of Example 1.

Embodiment 3

[0043] A bactericidal and odor-removing perfume composed of the following mass percentages of raw materials: 70% alcohol, 8% flavor, 4% deodorant, 3% bactericide, and isopropyl myristate made from corn as the main raw material by fermentation and deodorization Ester 3%, benzoin 0.8%, oak extract 0.01%, the balance is deionized water.

[0044] The preparation method of the bactericidal and odor-removing perfume of Example 3 is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com