Device for overcoming blasting foundation

A basic and circular technology, applied in the field of devices for overcoming blasting foundations, can solve the problems of difficulty in drilling operations in the next cycle, increasing construction costs, and increasing blasting operation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

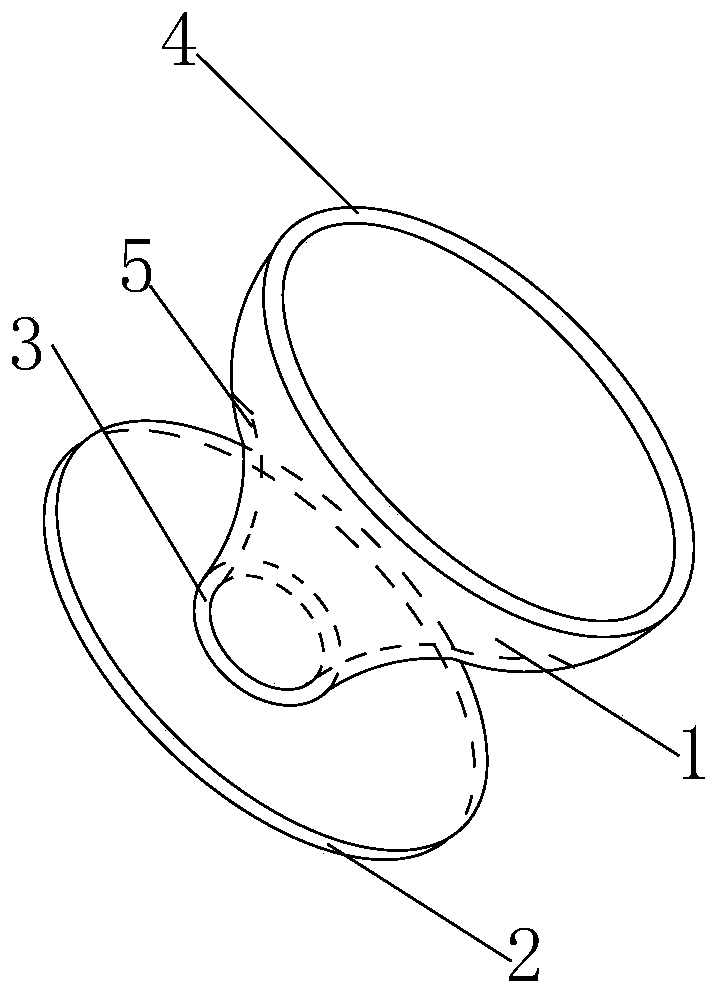

[0023] Such as figure 1 and figure 2 As shown, a device for overcoming the root of blasting includes an integrally formed charge fixing part 1 and a circular steel plate 2. The charge fixing part is in the shape of a funnel with an arc-shaped inner surface, and includes an upper charge fixing cavity and a circular steel plate 2. In the lower energy-gathering cavity, the funnel-shaped small head faces one side of the circular steel plate.

[0024] The inner surface of the energy-gathering cavity is covered with a layer of copper sheet 5, which is beneficial to transform the shock wave generated by the explosion into a high-energy metal jet, and further expands the lateral action range.

[0025] The opening of the funnel-shaped big head of the charge fixing part is a big circle 4, and the diameter of the big circle 4 is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com