Preparation method of self-organized periodic micro-nano structure with glass and crystal alternately arranged

A technology of micro-nano structure and alternate arrangement, applied in the direction of micro-structure technology, micro-structure device, manufacturing micro-structure device, etc. Solve problems such as limited dielectric materials, achieve the effect of improving thermal stability, reducing dispersion, and improving forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

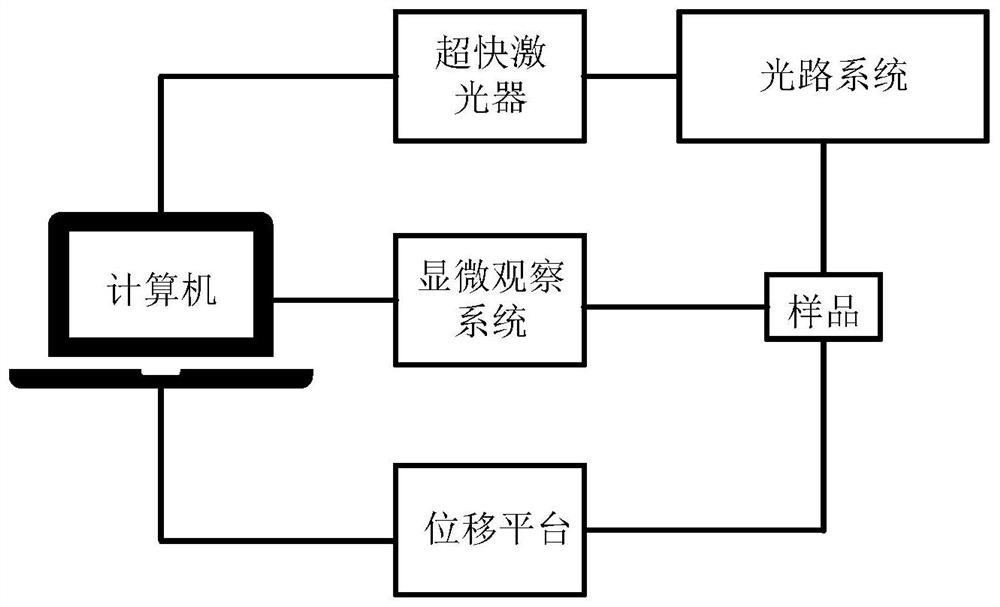

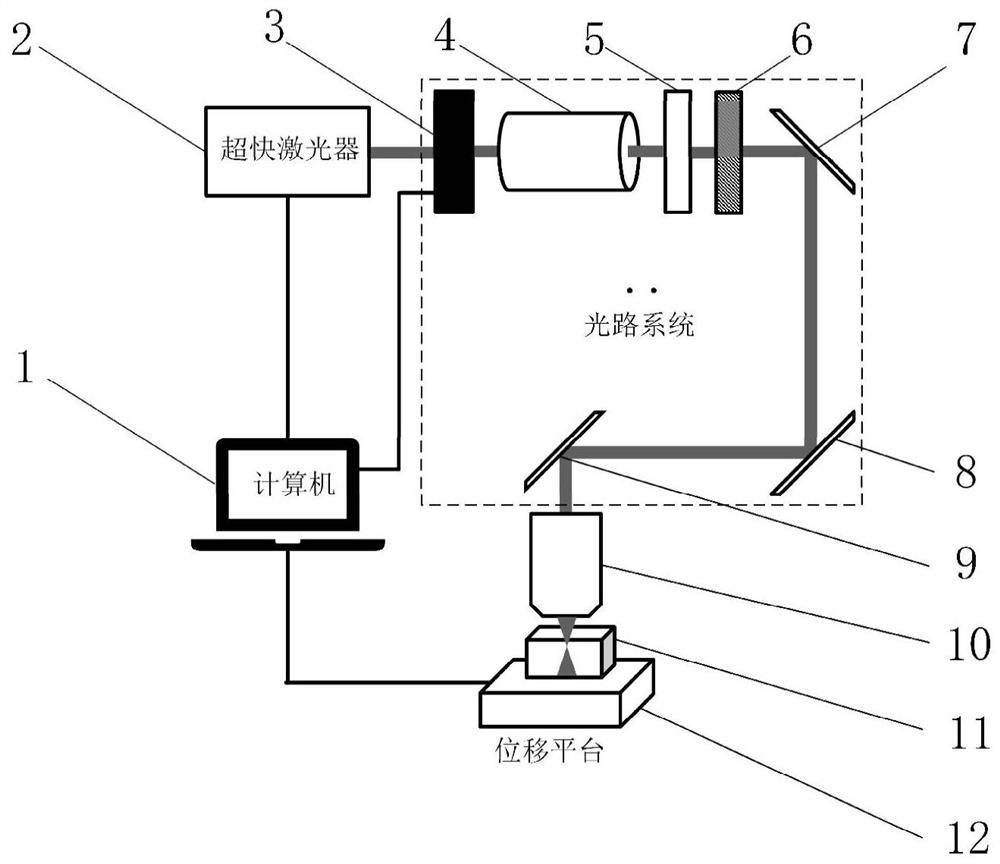

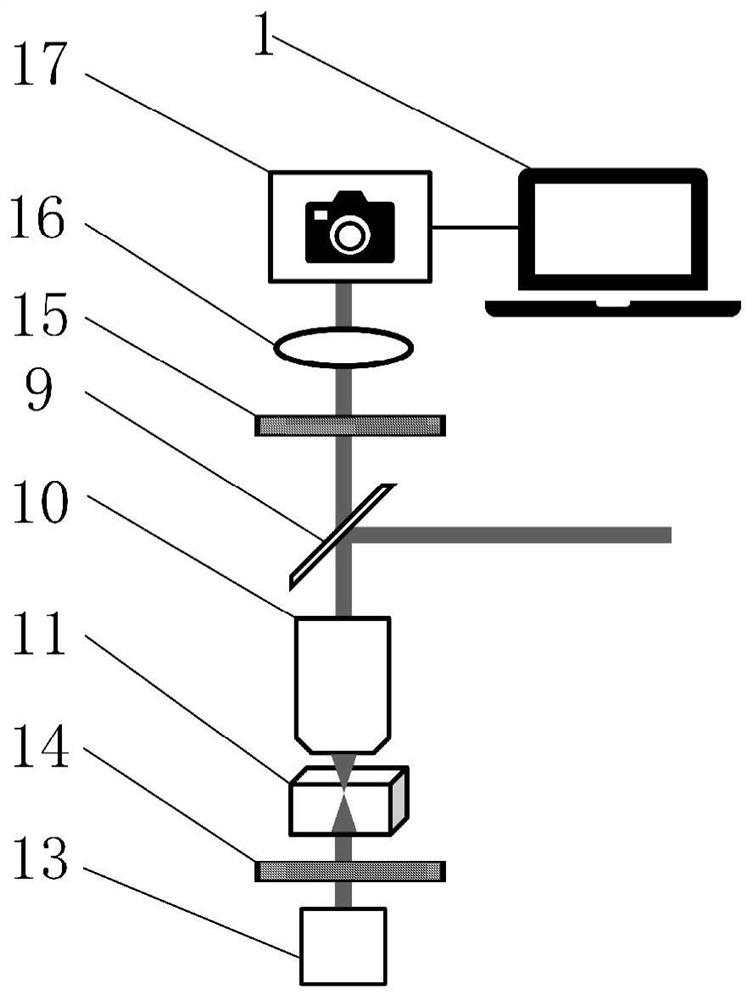

[0030] The preparation of the periodic micro-nano structure of the present invention is realized by using an ultrafast laser micro-nano processing manufacturing system. Such as figure 1 As shown, the ultrafast laser micro-nano processing manufacturing system includes a computer, an ultrafast laser, an optical system, a microscopic observation system and a displacement platform. The ultrafast laser is connected to the computer and controlled by the computer to output specific laser pulses; the optical system is coupled with the ultrafast laser to focus the ultrafast laser into the sample; the microscopic observation system is connected to the computer to observe the state of the sample and The processing process; the displacement platform is connected with the computer and controlled by the computer to realize the three-dimensional movement of the sample. Under the control of the computer, the ultrafast laser micro-nano processing and manufacturing system outputs laser pulses ...

Embodiment 1

[0037] Step 1: Prepare sample 11 by suspension method, sample 11 ternary glass 35La 2 o 3 -xTa 2 o 5 -(65-x)Nb 2 o 5 (5

[0038] Adjust Ta by setting 2 o 5 or TiO 2 The mole percentage x of x adjusts the crystallization ability of sample 11. The larger x is, the stronger the crystallization ability of sample 11 is, the easier it is to induce micro-nano structures, and the faster the processing speed used, but the preparation of sample 11 will become more difficult. The specific implementation of the present invention sets Ta 2 o 5 or TiO 2 The mole percentage x can well realize the preparation of periodic micro-nano structures with alternating glass-crystal arrangements.

[0039] Step 2: Fix the sample 11 on the displacement platform 12, find a position suitable for processing through the microscopic observation system, and determine its xyz three-axis coordinates for subsequent setting of motion parameters.

[...

Embodiment 2

[0047] Step 1: Prepare sample 11 by suspension method, sample 11 ternary glass 35La 2 o 3 -xTiO 2 -(65-x)Nb 2 o 5 (30

[0048] Adjust Ta by setting 2 o 5 or TiO 2 The mole percentage x of x adjusts the crystallization ability of sample 11. The larger x is, the stronger the crystallization ability of sample 11 is, the easier it is to induce micro-nano structures, and the faster the processing speed used, but the preparation of sample 11 will become more difficult. The specific implementation of the present invention sets Ta 2 o 5 or TiO 2 The mole percentage x can well realize the preparation of periodic micro-nano structures with alternating glass-crystal arrangements.

[0049] Step 2: Fix the sample 11 on the displacement platform 12, find a position suitable for processing through the microscopic observation system, and determine its xyz three-axis coordinates for subsequent setting of motion parameters.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com