Vacuumizing and nitrogen filling sealing machine

A nitrogen filling and sealing machine technology, applied in the direction of pressurization/gasification packaging, packaging, etc., can solve the problems such as the residual oxygen content of the sealed tank body is not up to standard, the powder cannot be completely compacted, and the air remains, so as to improve production. The effect of working efficiency, reducing equipment cost and reducing space occupancy rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

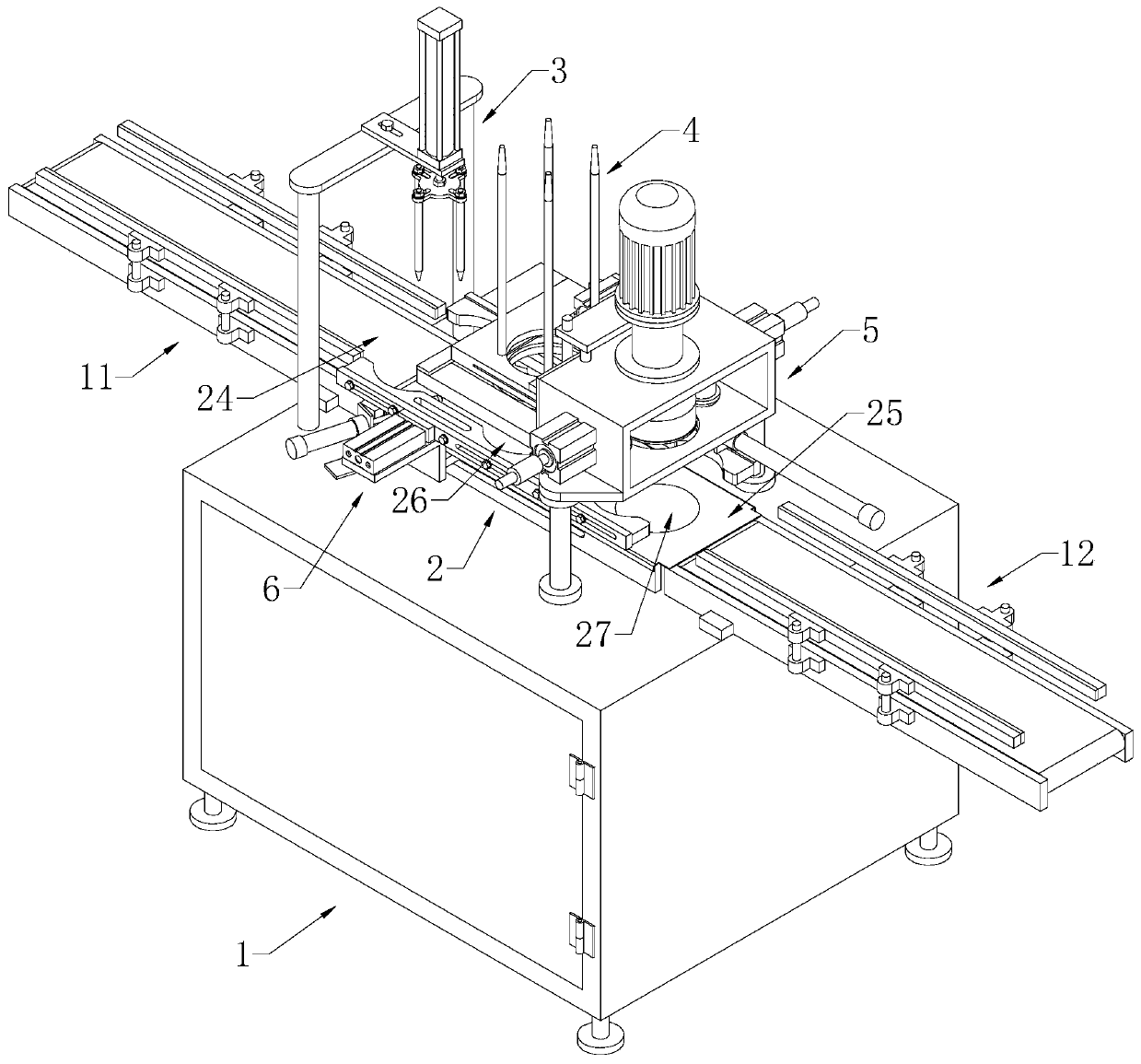

[0043] Such as figure 1 As shown, a vacuum-pumping and nitrogen-filling sealing machine includes a frame 1 on which a conveying track 2 is erected, and the feed end 24 and the discharge end 25 of the conveying track 2 are respectively connected with a feed line body 11 and a feed end 25. The discharge line body 12 is provided with a perforating device 3 , an upper cover device 4 and a sealing device 5 sequentially from the feed end 24 to the discharge end 25 of the conveying track 2 . The tank body and the cover body are transported to the sealing device 5 via the conveying track 2 and the upper cover device 4 respectively, and the vacuuming operation and the nitrogen filling operation of the tank body are completed through the sealing device 5, and then the sealing operation of the tank body and the cover body is completed. In this way, the automatic operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com