Tire burst emergency device

An emergency device and tire blowout technology, which is applied to tire parts, transportation and packaging, vehicle parts, etc., can solve the problems of high cost, heavy weight, and increased vehicle weight, and achieve the effect of light weight and increased weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

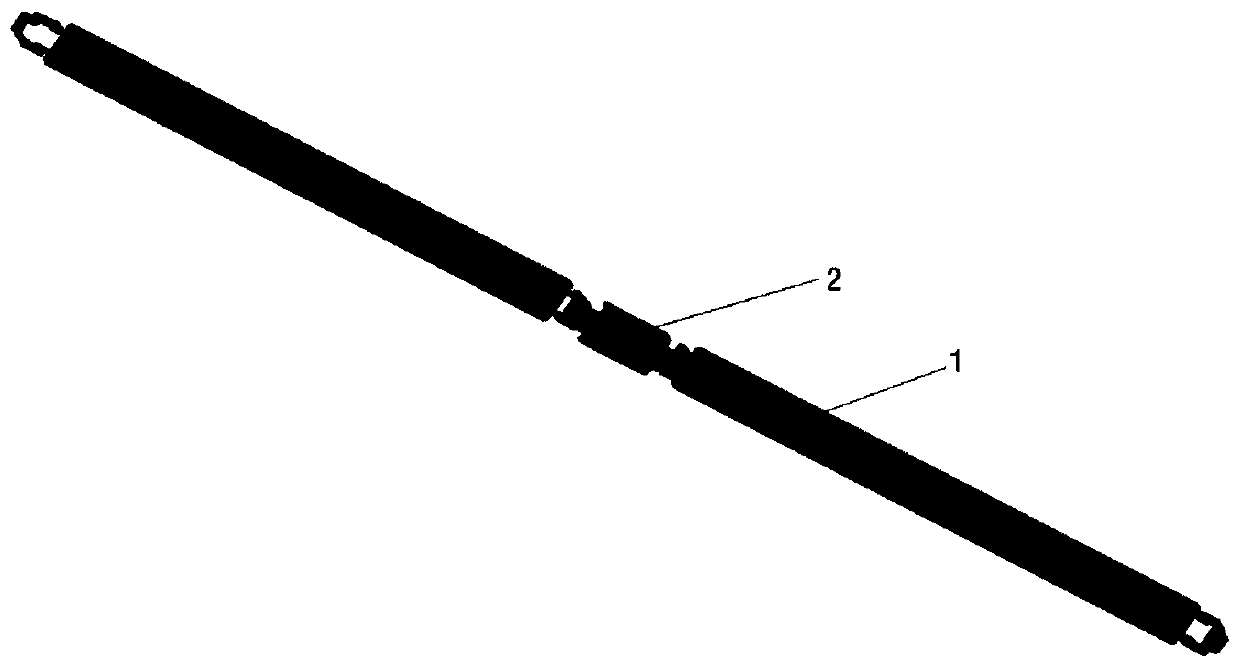

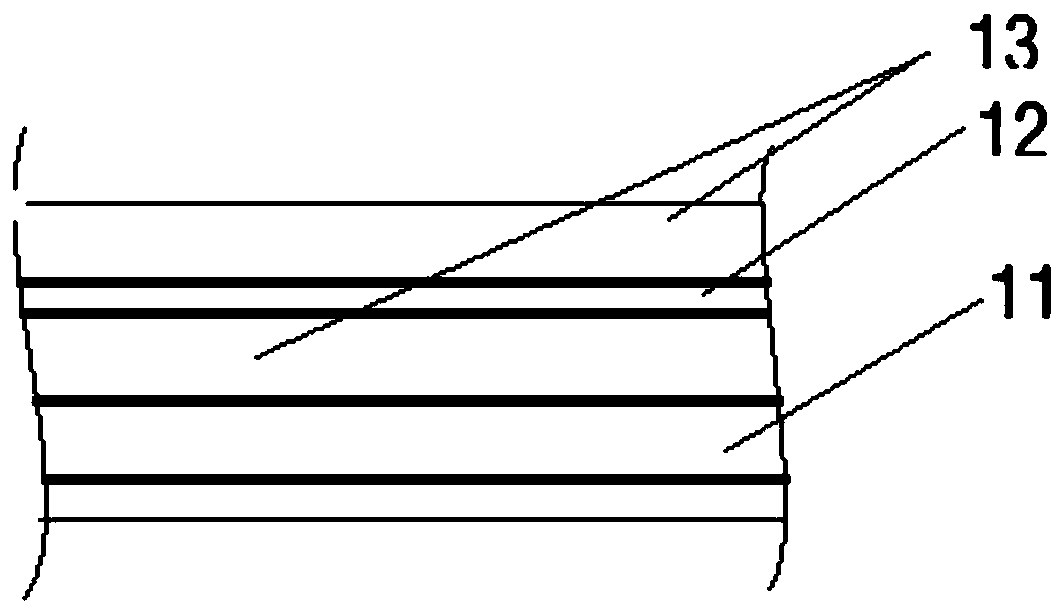

[0039] Tire burst emergency device of the present invention, see figure 1 and figure 2As shown, it includes: a belt-shaped body formed by connecting explosion-proof belt units 1 in series, and the belt-shaped body is circumferentially arranged in close contact with the surface of the hub. The explosion-proof belt unit includes a lower manganese steel layer 11 and an upper cord fabric layer 12, and the rubber layer 13 separates and wraps the manganese steel layer 11 and the cord fabric layer 12 through vulcanization. Two adjacent explosion-proof units are assembled by means of rubber circlip pins. The carcass layer 12 is located between the rubber 13 and the manganese steel layer 11 at a position of one-third to two-thirds. The outermost surface of the main rubber layer adopts a plum pattern pattern such as Figure 5 shown.

[0040] The above-mentioned device is composed of various parts. The main part is composed of rubber, high and low temperature resistant manganese ste...

Embodiment 2

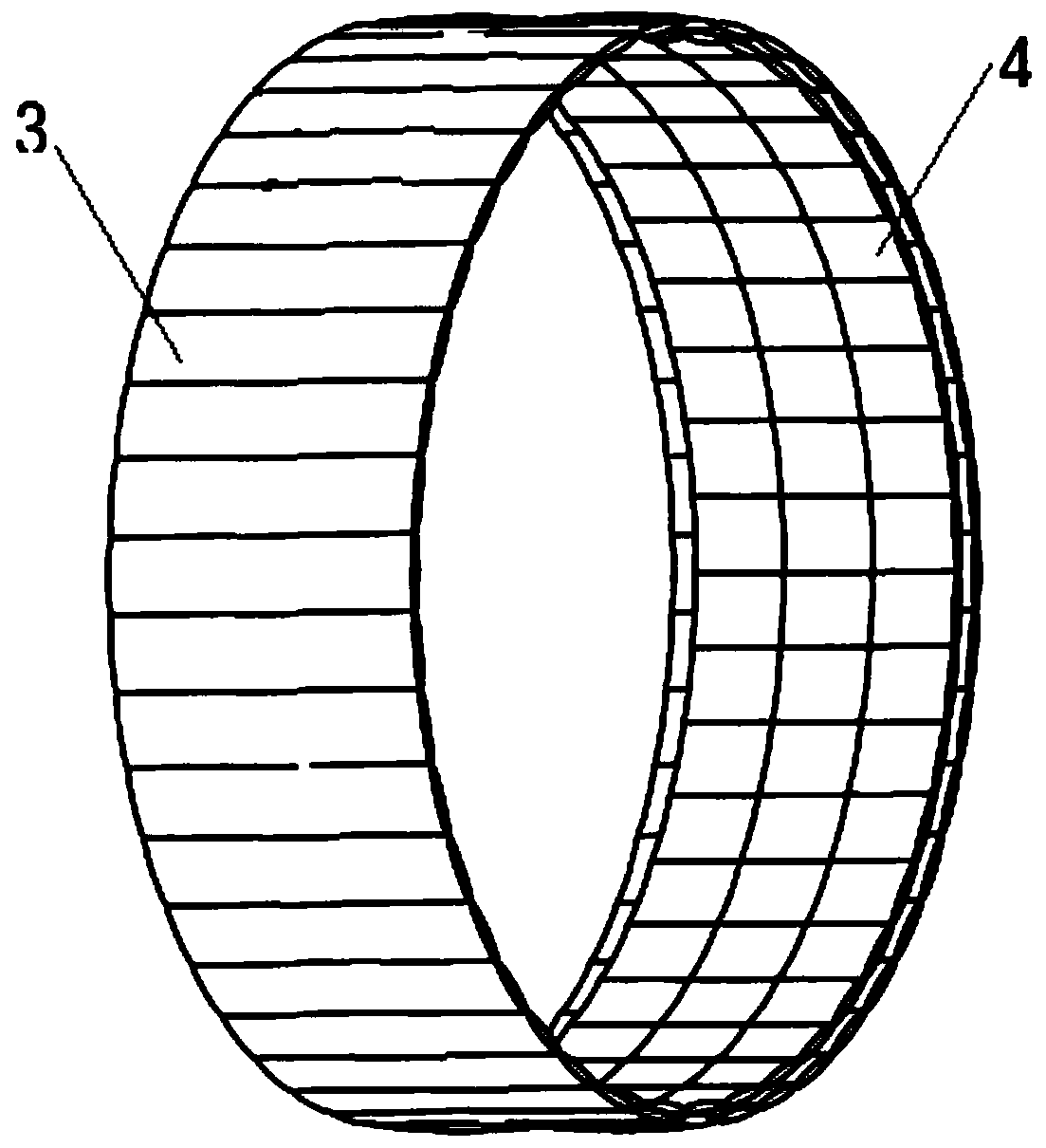

[0042] Tire burst emergency device of the present invention, see image 3 As shown, the explosion-proof band unit includes a unit capsule 3 and a shear thickening liquid filled in the capsule 3 .

[0043] Specifically, the height of the bladder is 1 / 3-2 / 3 of the height from the inner surface of the tire to the hub. The capsule is made of rubber or polymer material with strong flexibility; the thickness of the capsule is 3.0mm-5.0mm. The shear thickening liquid is a non-Newtonian fluid filling material, and the shear thickening liquid is water starch or a stable suspension liquid dissolved in polyethylene glycol or ethylene glycol.

[0044] Preferably, the sealed airbag 4 is bonded to the lower part of the capsule 3 filled with the shear thickening liquid, so as to prevent the apparent viscosity of the explosion-proof belt from increasing exponentially in milliseconds and causing damage to the hub when it becomes a hard solid.

[0045] The technical indicators of the comprehe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com