Glass bracket oil coating and error detecting mechanism

A glass bracket, oiling technology, applied in the direction of coating, liquid coating device on the surface, geophysical measurement, etc., can solve problems such as incorrect installation, worker's missing installation, grease accumulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

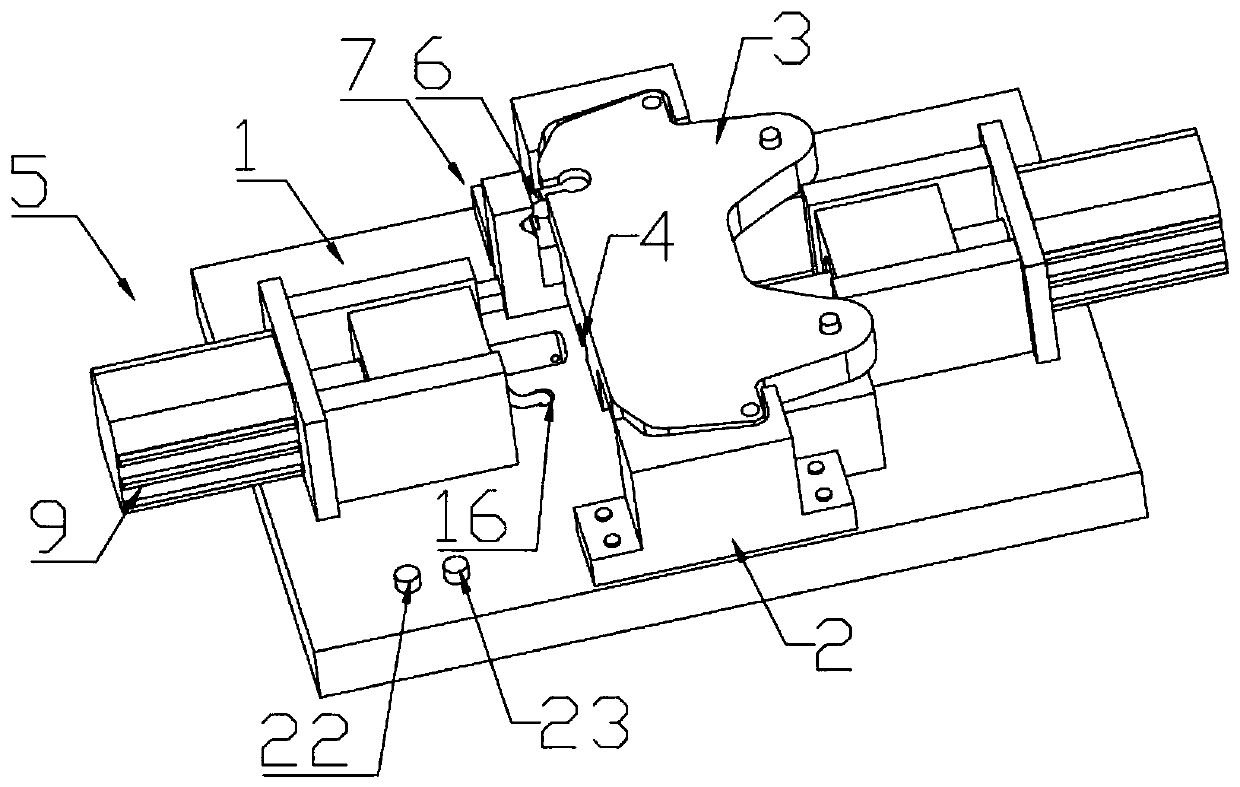

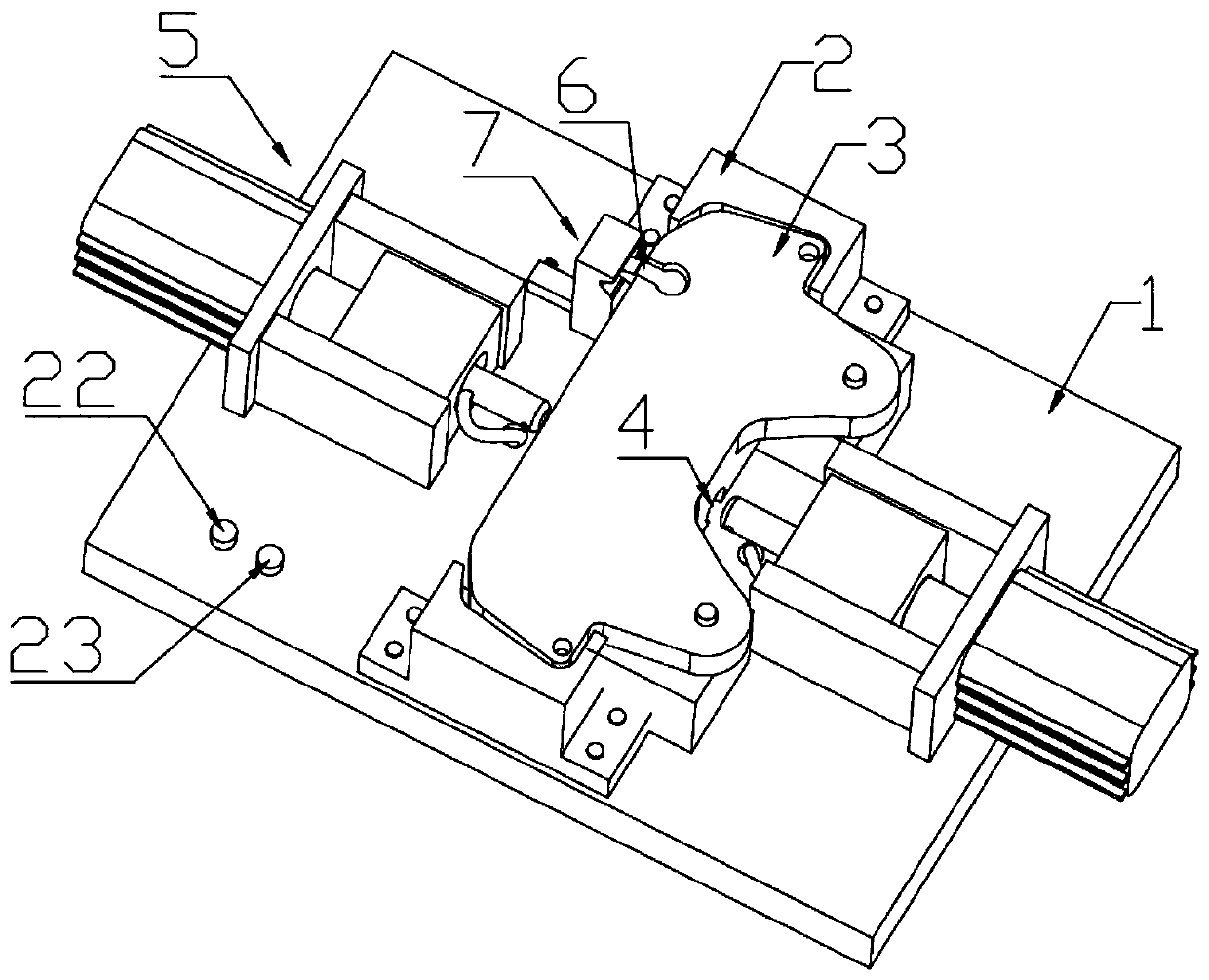

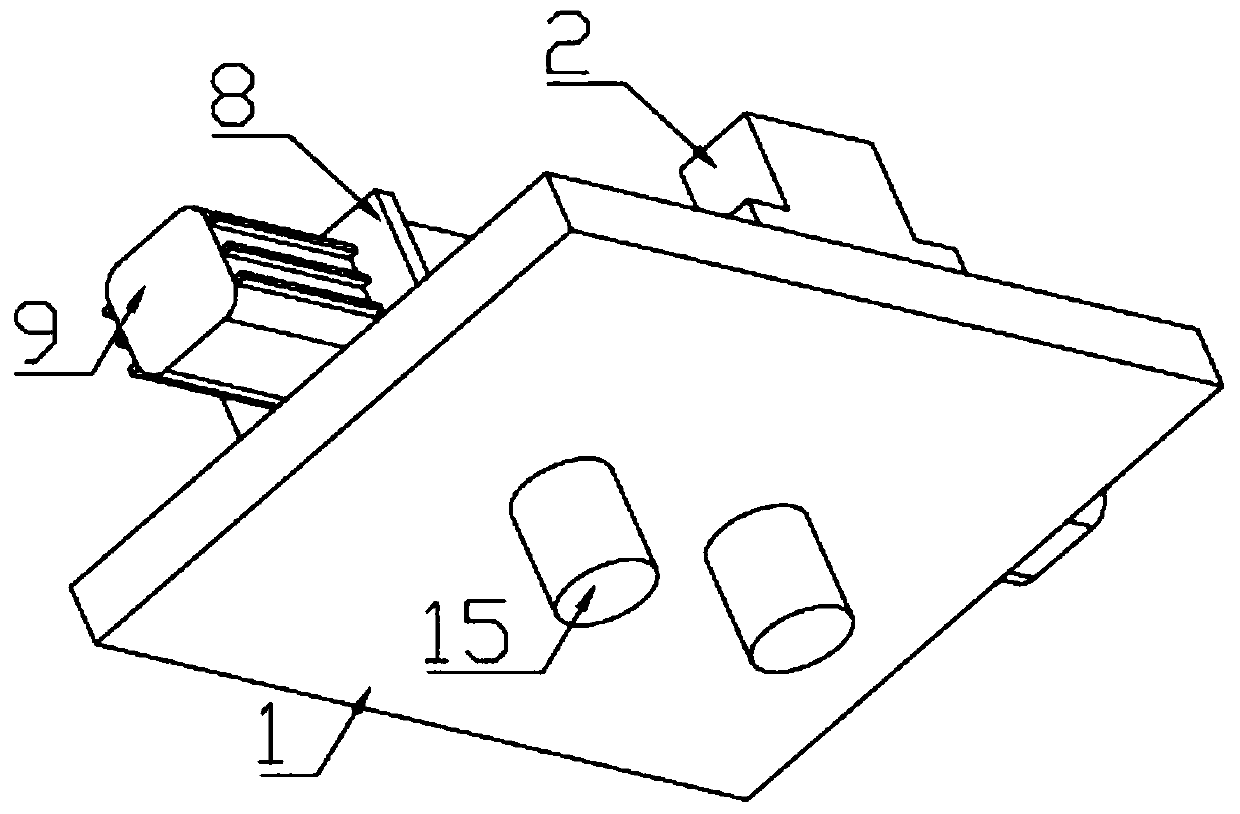

[0018] Such as Figure 1 to Figure 7 As shown, a glass bracket oiling and error detection mechanism includes a mounting plate 1, and the mounting plate 1 is provided with two positioning blocks 2 with the same structure and positioning the glass bracket 3. The mounting plate 1 There are two groups of oiling mechanisms 5 symmetrically distributed on both sides of the glass bracket 3 and oiling the installation position 4 of the cable spring head on both sides of the glass bracket 3. The mounting plate 1 is also provided with a pair of glass brackets. The buffer block 6 on the 3 carries out the anti-error mechanism 7 of online detection whether to install.

[0019] In this embodiment, the oiling mechanism 5 includes a support frame 8 installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com