Vacuum flask assembling method

An assembly method and thermos bottle technology, which are applied to non-pressure containers, household appliances, fixed-capacity gas storage tanks, etc., can solve problems such as lack of airtightness, falling thermos, hidden safety hazards, etc., to avoid boiling water splashing, Avoid the effect of scalding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

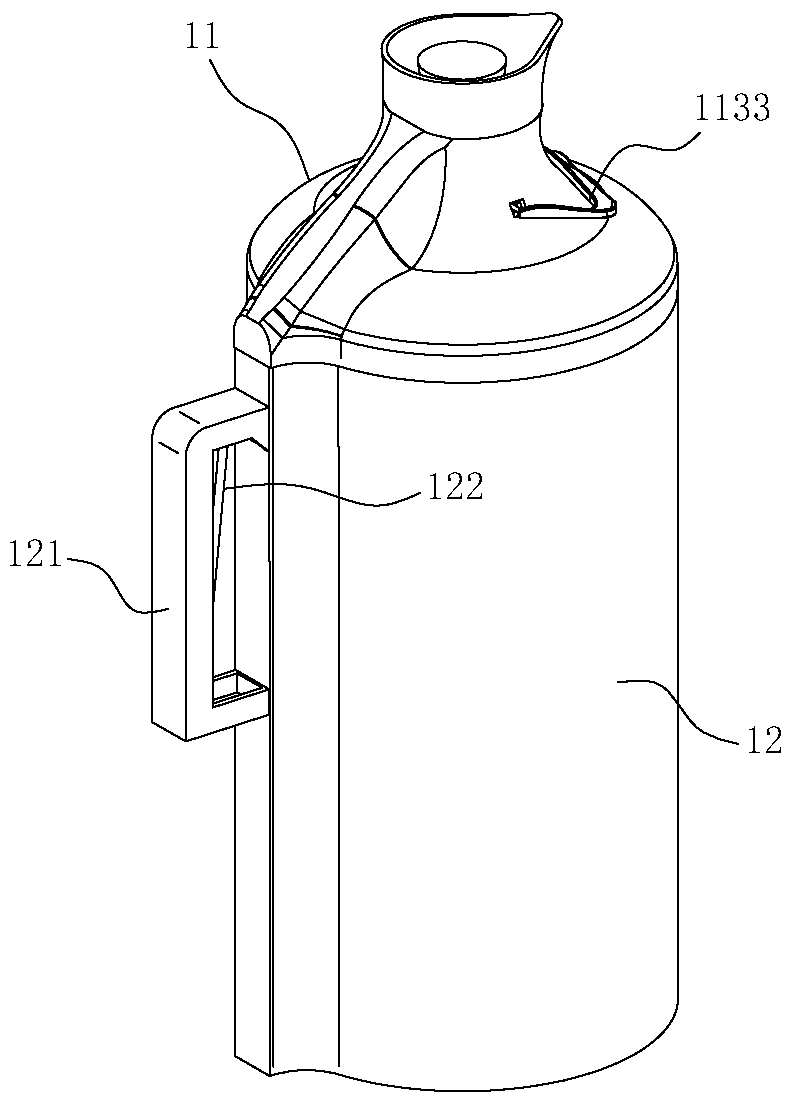

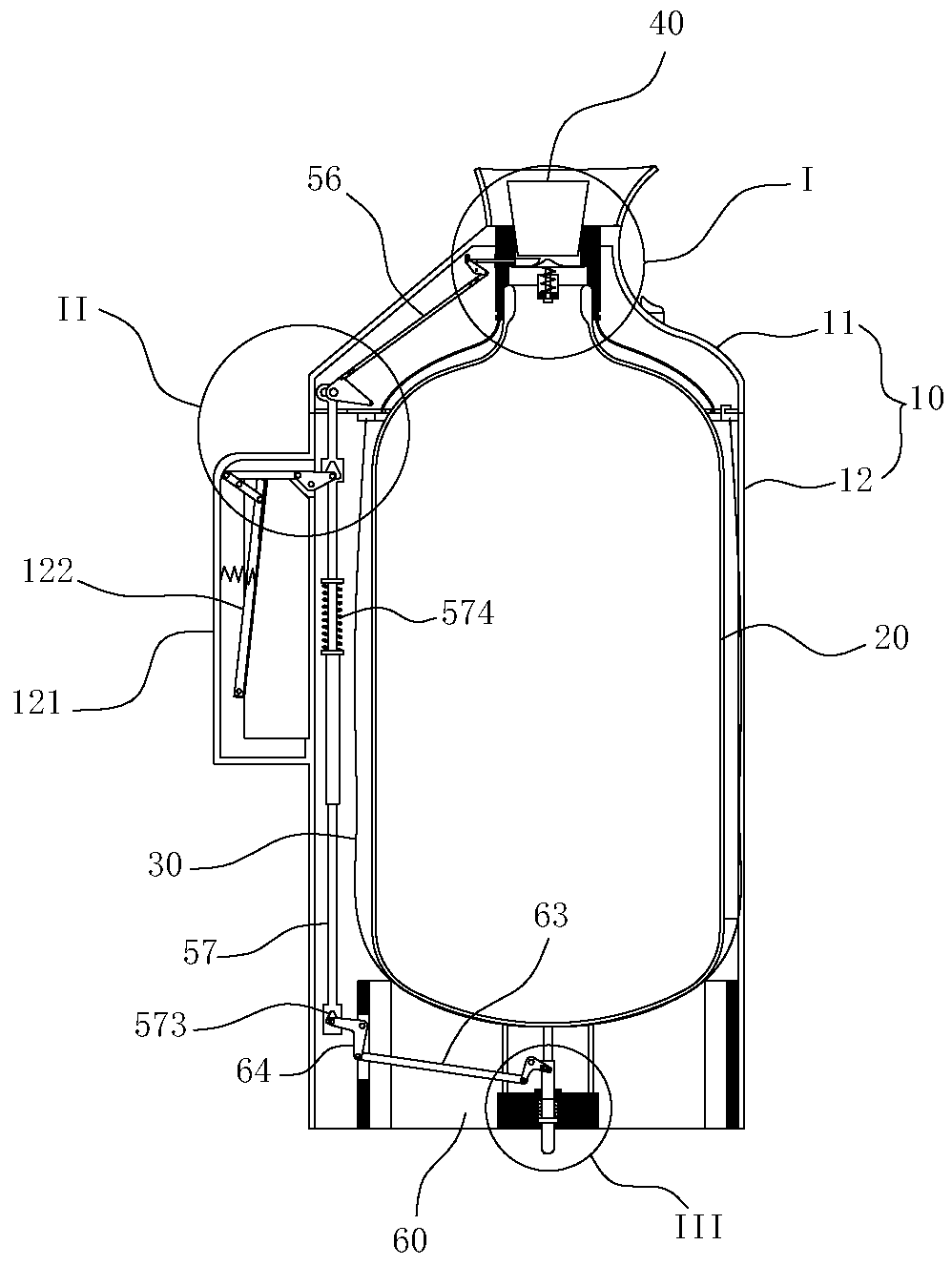

[0028] Such as figure 1 , 2 As shown in , 3, a safety thermos bottle includes a shell 10, an inner container 20 and a bottle stopper 40, and also includes an explosion-proof pouch 30, which is set outside the inner container 20, and the explosion-proof pouch 30 together with the inner The bladder 20 is installed in the housing 10 . The present invention installs an explosion-proof pouch 30 on the outside of the inner tank 20 on the basis of the traditional thermos bottle. When the thermos bottle falls accidentally, the explosion-proof pouch 30 can effectively avoid boiling water splashing and scalding.

[0029] Preferably, the outer ring surface of the bottle mouth of the liner 20 is detachably and hermetically connected to the inner ring surface of the top opening of the casing 10 , and the upper end of the explosion-proof pouch 30 is fixedly connected to the inner wall of the top opening of the casing 10 . The explosion-proof bag 30 is connected with the shell 10, even if ...

Embodiment 2

[0035] The present invention also provides a method for assembling a thermos bottle. The thermos bottle includes an outer shell 10, an inner tank 20, a bottle stopper 40 and an explosion-proof pouch 30. Then the liner 20 and the explosion-proof pouch 30 are loaded into the shell 10 .

[0036] Specifically, the installation method between the liner 20 and the shell 10 is: insert the bottle mouth of the liner 20 from the bottom of the top opening of the shell 10 into the top opening of the shell 10 and ensure sealing; The assembly method is as follows: the upper end of the explosion-proof bag 30 is sealed and connected to the inner wall of the top opening of the casing 10 .

[0037] Specifically, the shell 10 is composed of a bottle shoulder 11 and a bottle body 12, the bottle shoulder 11 is detachably connected to the bottle body 12; the explosion-proof pouch 30 is spliced by an upper half 31 and a lower half 32 wherein the upper and lower ends of the upper half 31 are fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com