Production method of radix angelicae dahuricae herbal tea clearing away heat and toxic materials

A technology for clearing away heat and detoxification and a production method, applied in the direction of tea extraction, etc., can solve the problems of poor taste, lack of Angelica dahurica, single ingredients, etc., and achieve the effects of fine taste, delaying skin aging, and good taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

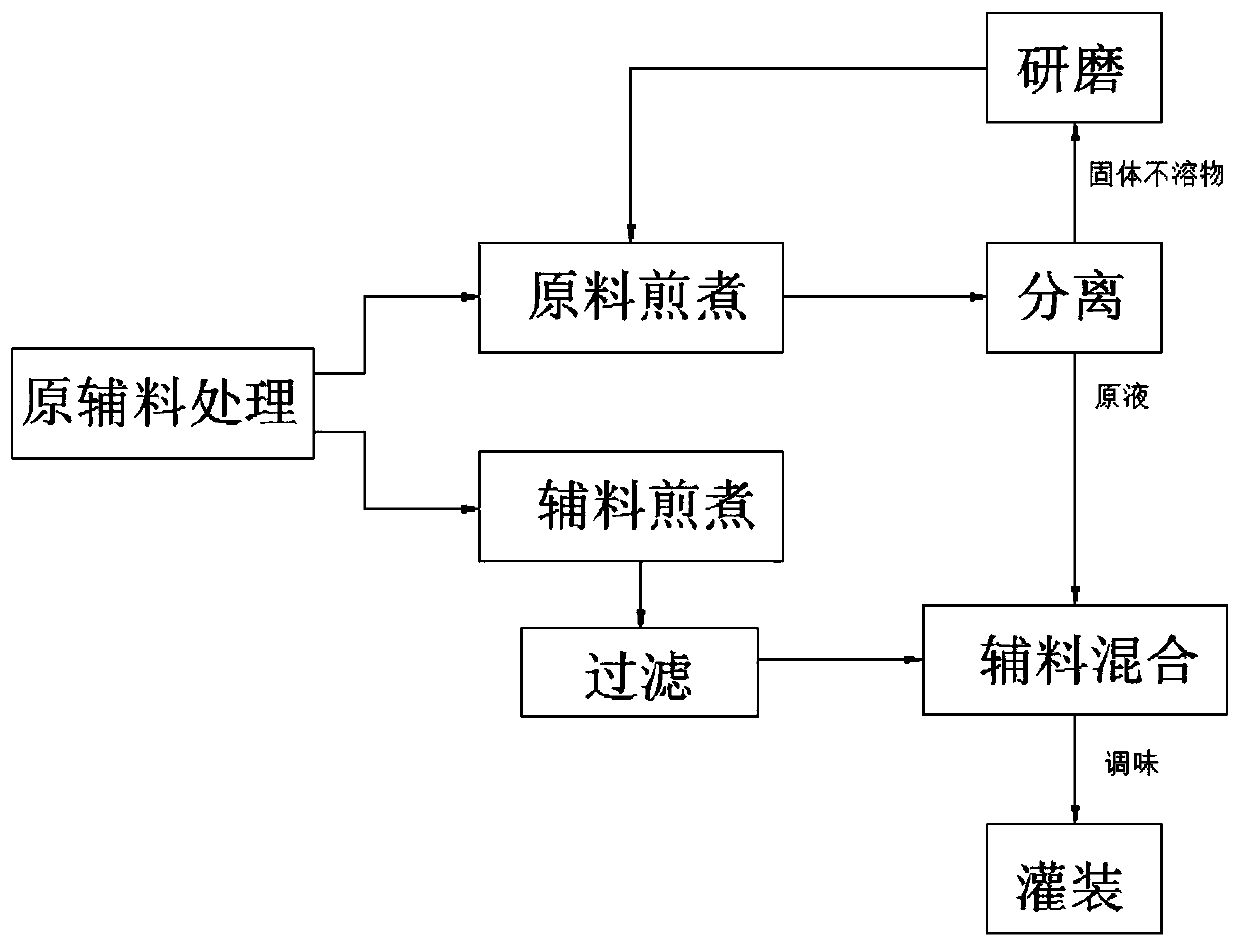

[0019] Example 1, see figure 1 ;

[0020] S1: Raw and auxiliary materials processing, wash the raw materials of Angelica dahurica, mint, frangipani, cloth slag leaves, chrysanthemum, honeysuckle, prunella vulgaris, licorice, dry and crush them, add them to the corresponding decoction tank, and then add water;

[0021] S2: Decocting raw materials and auxiliary materials, decocting the raw materials under high pressure, setting the pressure to 150KPa, setting the time to 2h, decocting the auxiliary materials, and setting the ratio of the auxiliary materials to 4% mint, 4% frangipani, 4% cloth Slag leaves, 4% chrysanthemum, 4% green tea, 2% honeysuckle, 5% cassia, 2% licorice and 71% water, the time is set to 1h, and then filtered to prepare the auxiliary material liquid for later use;

[0022] S3: Separation of raw materials, pouring the decoction liquid of raw materials into a separator for solid-liquid separation to obtain the raw liquid of Angelica dahurica and solid insolub...

Embodiment 2

[0026] Example 2, see figure 1 ;

[0027] S1: Raw and auxiliary materials processing, wash the raw materials of Angelica dahurica, mint, frangipani, cloth slag leaves, chrysanthemum, honeysuckle, prunella vulgaris, licorice, dry and crush them, add them to the corresponding decoction tank, and then add water;

[0028] S2: Decocting raw materials and auxiliary materials, decocting the raw materials under high pressure, setting the pressure to 150KPa, setting the time to 2h, decocting the auxiliary materials, and setting the ratio of the auxiliary materials to 5% mint, 5% frangipani, 5% cloth Slag leaves, 5% chrysanthemum, 5% green tea, 4% honeysuckle, 6% cassia, 4% licorice and 61% water, set the time to 1h, then filter, and prepare the auxiliary material liquid for later use;

[0029] S3: Separation of raw materials, pouring the decoction liquid of raw materials into a separator for solid-liquid separation to obtain the raw liquid of Angelica dahurica and solid insoluble matt...

Embodiment 3

[0033] Example 3, see figure 1 ;

[0034] S1: Raw and auxiliary materials processing, wash the raw materials of Angelica dahurica, mint, frangipani, cloth slag leaves, chrysanthemum, honeysuckle, prunella vulgaris, licorice, dry and pulverize them, add them to the corresponding decoction tank, and then add water;

[0035] S2: Decocting raw materials and auxiliary materials, decocting the raw materials under high pressure, setting the pressure to 150KPa, setting the time to 2h, decocting the auxiliary materials, and setting the ratio of the auxiliary materials to 5% mint, 5% frangipani, 5% cloth Slag leaves, 5% chrysanthemum, 5% green tea, 4% honeysuckle, 6% cassia, 4% licorice and 61% water, the time is set to 1h, and then filtered to prepare the auxiliary material liquid for later use;

[0036] S3: Separation of raw materials, pouring the decoction liquid of raw materials into a separator for solid-liquid separation to obtain the raw liquid of Angelica dahurica and solid ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com