Tunable all-solid-state white light laser system

A white-light laser and all-solid-state technology, applied to lasers, laser components, phonon exciters, etc., can solve the problems of complex beam combination, lower production efficiency, increase production steps and costs, etc., and achieve white light chromaticity adjustment Flexible, Easy to Integrate, Satisfies the Effects of Colorimetrically Stringent Applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

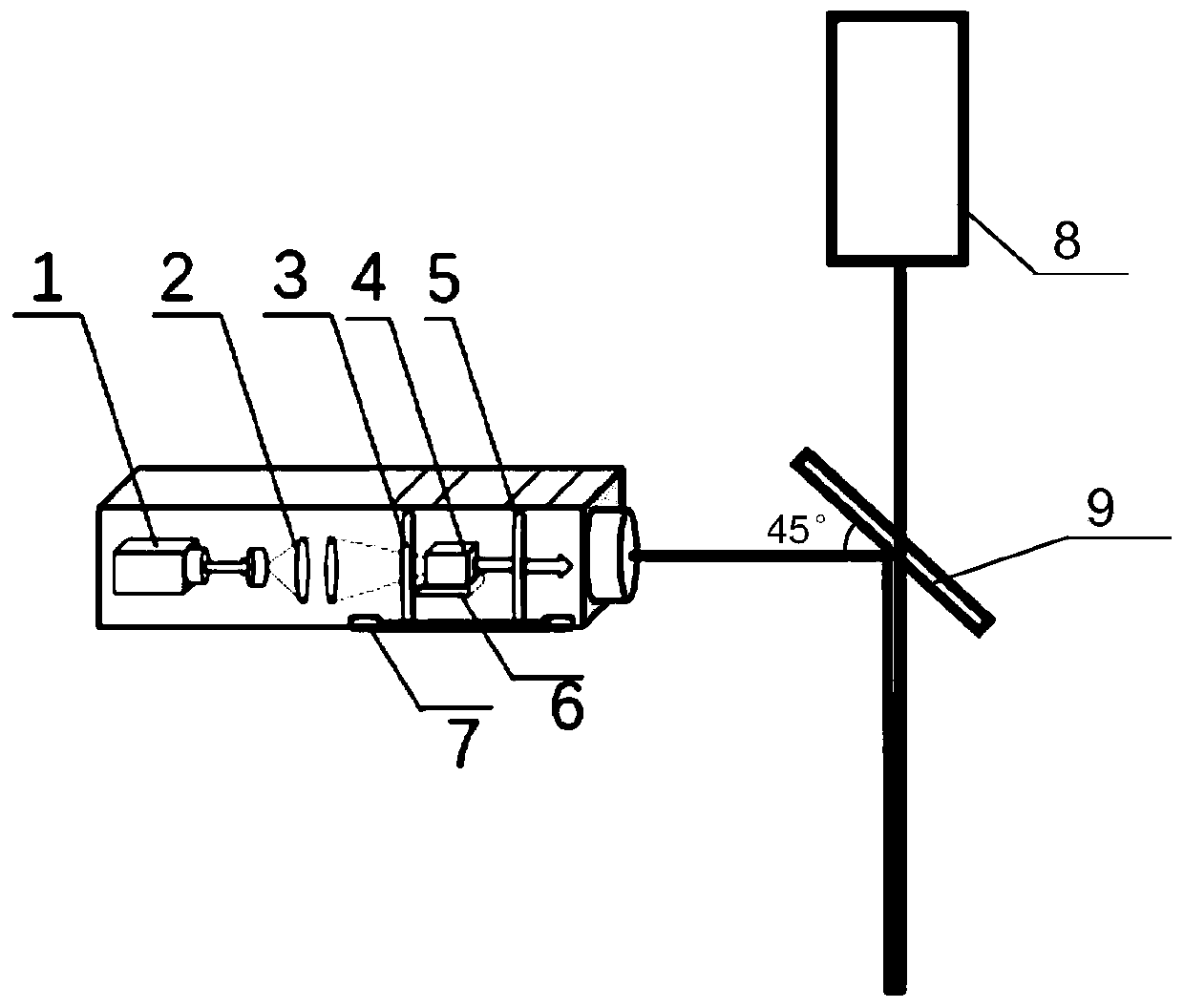

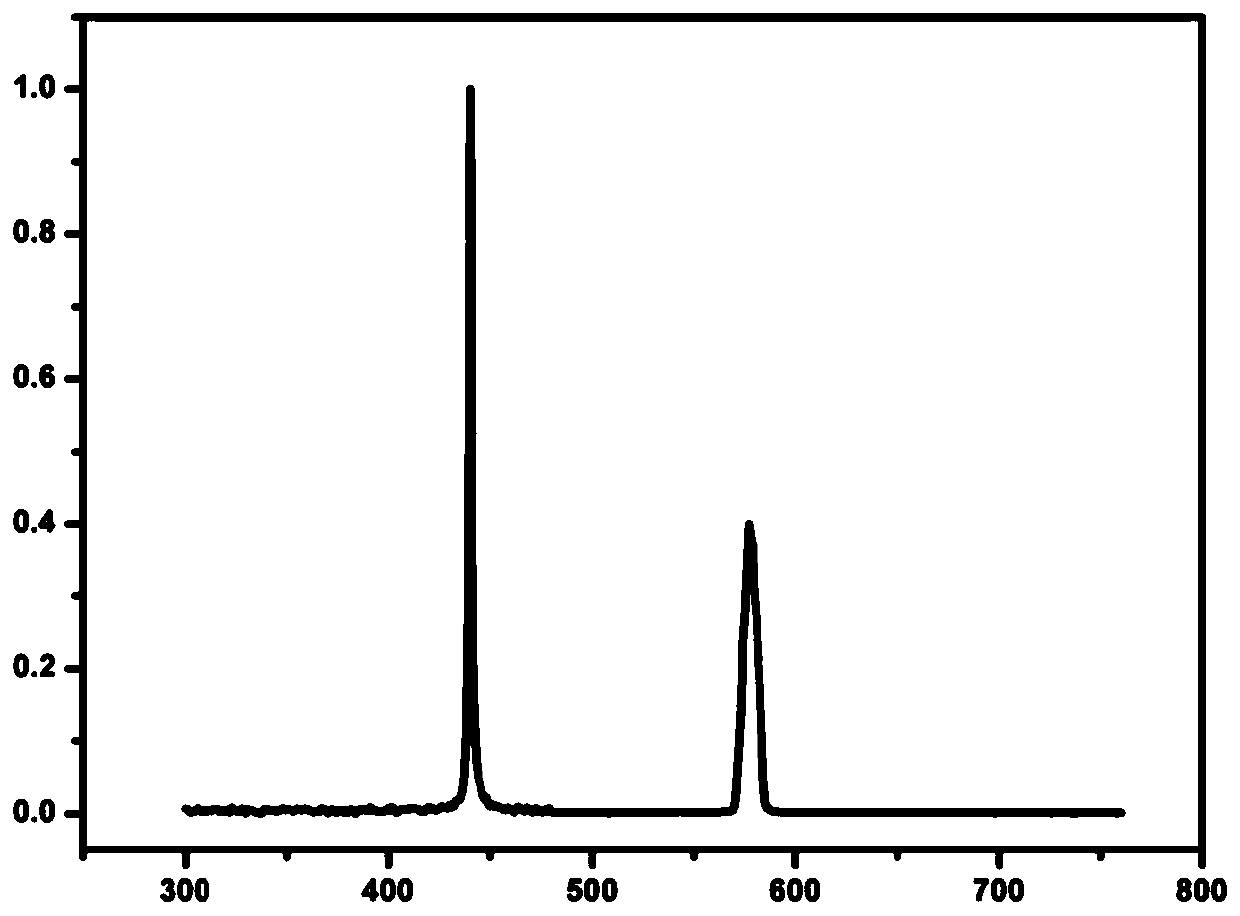

[0043] A tunable all-solid-state white-light laser system, such as figure 1 As shown, it includes a blue LD 8, a self-frequency doubling yellow laser and a laser beam combining component. The light emitted by the blue LD 8 and the self-frequency doubling yellow laser are combined to form a white laser by the laser beam combining component, wherein the blue The working wavelength of LD 8 is 440nm, and the working wavelength of self-frequency doubling yellow laser is 577nm;

[0044] In this embodiment, the laser beam combining group is a beam splitter assembly, and the beam splitter assembly includes a beam splitter 9, and the yellow light beam emitted from the frequency-doubled yellow laser is incident on the yellow beam of the beam splitter 9 at an incident angle of 45°. The light reflection mirror surface changes the direction of the light path by 90°, and merges with the blue light beam emitted by the blue light LD 8 and perpendicular to the incident direction of the yellow ...

Embodiment 2

[0049] A tunable all-solid-state white light laser system, its structure is as shown in Embodiment 1, the difference is that the non-laser active area of the laser self-frequency doubling crystal is provided with a semiconductor cooling plate 6, which is close to the non-laser area of the self-frequency doubling crystal. In the laser action area, the temperature of the laser self-frequency doubling crystal is stabilized within a certain range (5-30°C).

Embodiment 3

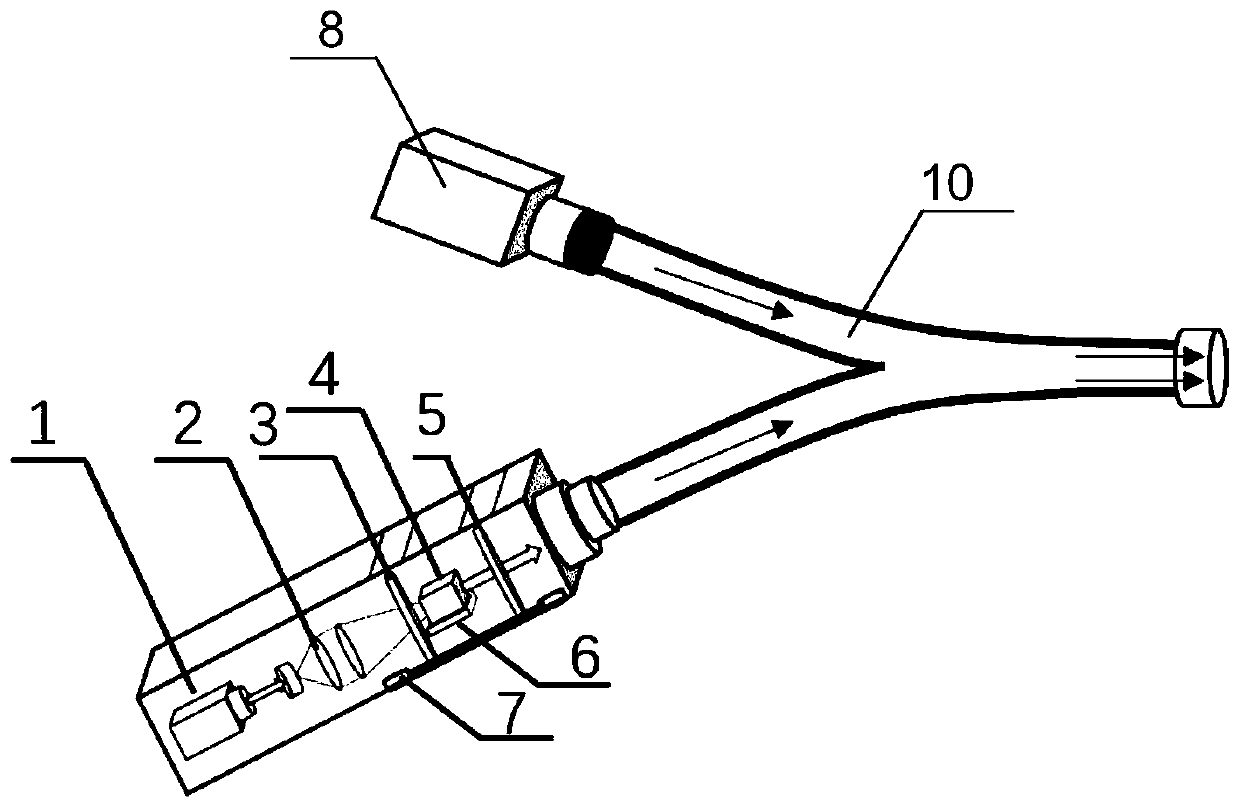

[0051] A tunable all-solid-state white light laser system, its structure is as shown in embodiment 1, the difference is, as figure 2 As shown, the laser beam combining component is an optical fiber combining component. The fiber combining component includes an optical fiber 10, two ports A at the head end and a port B at the tail end. 8. The other port A is connected with a self-frequency doubling yellow laser, leading the light emitted by the blue LD 8 and the self-frequency doubling yellow laser into the optical fiber 10 so that the blue light and yellow light are mixed and combined inside the fiber , directly output the mixed white light through port B at the end of the fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com