A dynamic and static vertical loading device for electric wheel performance testing test bench

A technology of dynamic loading and static loading, which is applied in the direction of measuring devices, vehicle testing, mechanical parts testing, etc., can solve the problems of increased vertical load, decreased control accuracy and response speed, high cost, etc., and achieves the goal of reducing torque capacity Requirements, improvement of load control accuracy, effect of size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] specific implementation plan

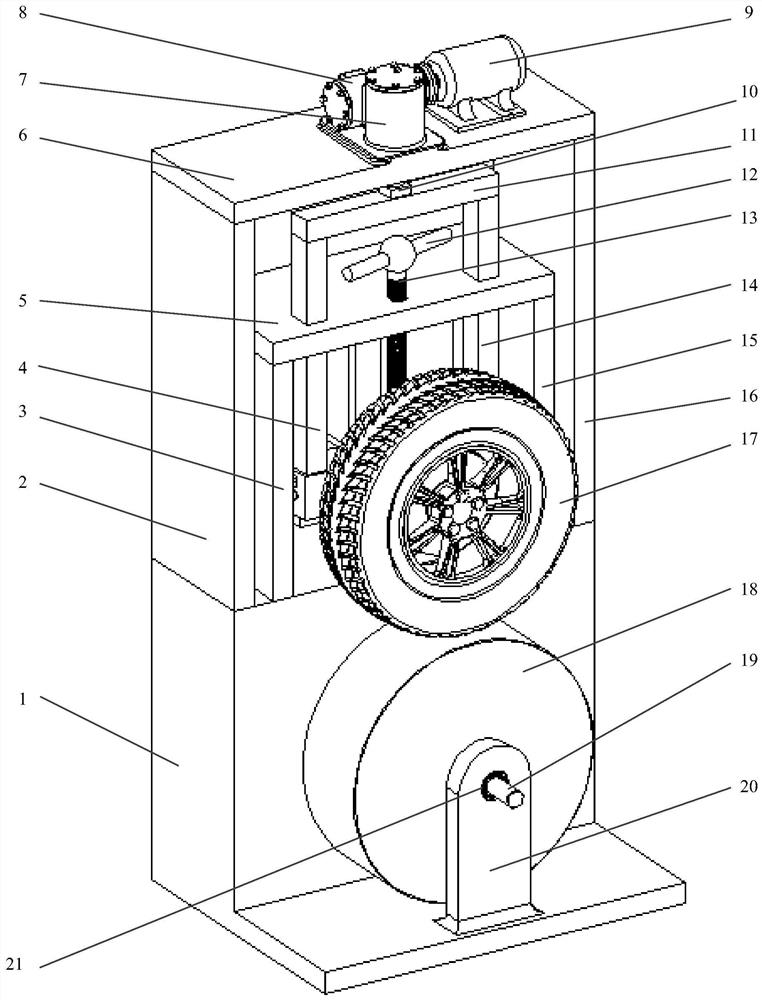

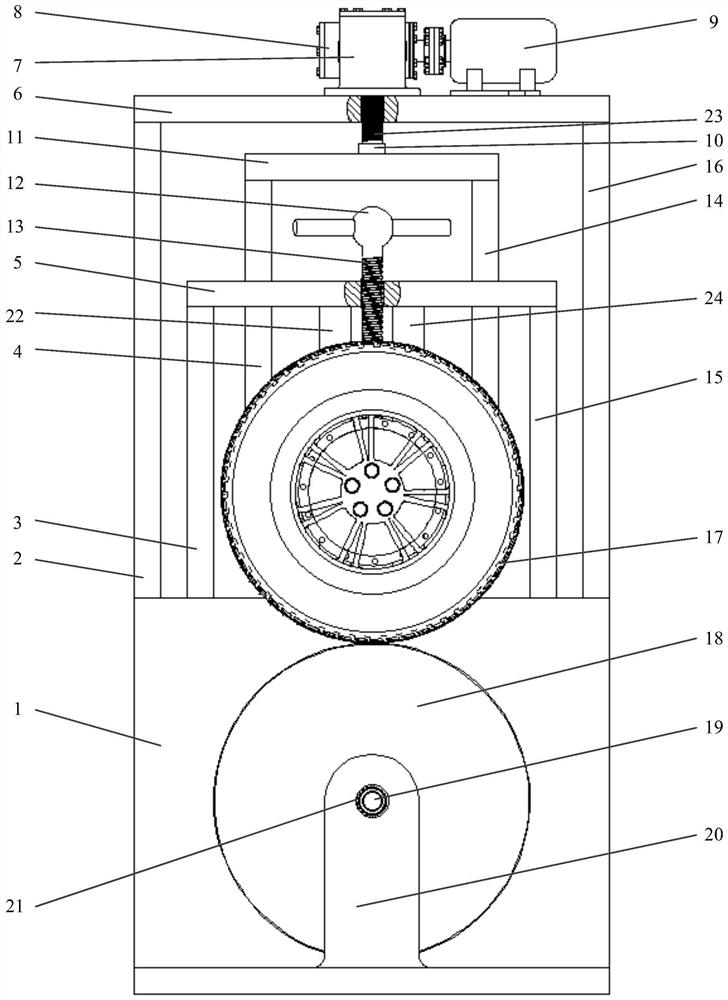

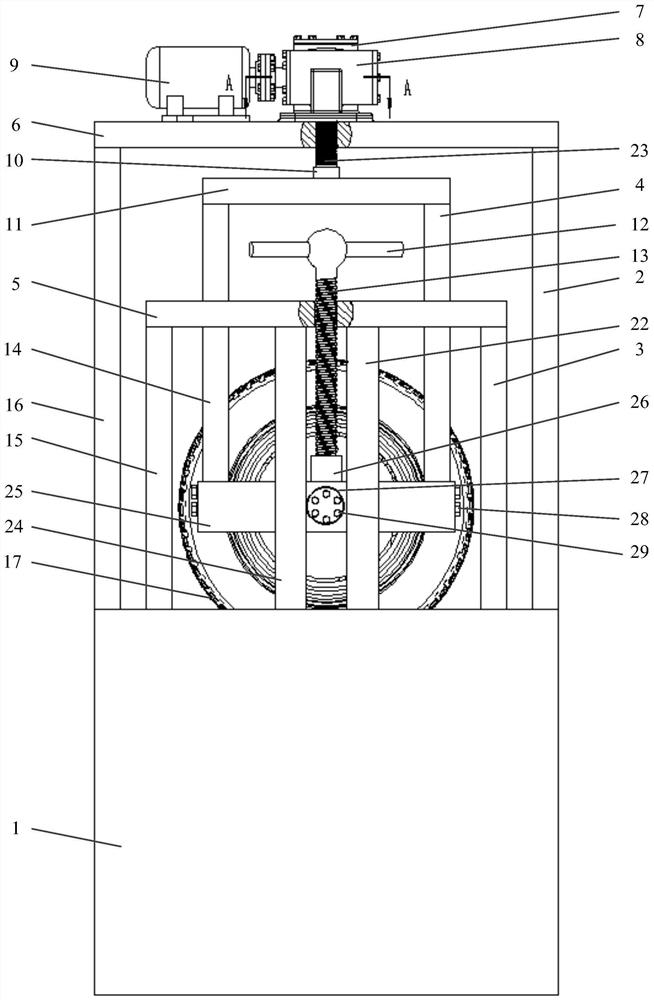

[0043] The object of the present invention is to provide a dynamic and static vertical loading device for electric wheel performance test bench, the electric wheel vertical load loading device can realize both static load vertical loading and dynamic load vertical loading, and dynamic The load loading device is simple and easy to control, and the cost is low; the vertical force applied to the electric wheel by the dynamic and static loading device can simulate the wheel load transfer caused by acceleration, deceleration, and turning during the road driving of the real vehicle, so that the test bench The vertical force of the electric wheel is close to the vertical force of the electric wheel when the real vehicle is running on the road.

[0044] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0045] A dynamic and static vertical loading device for electric wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com