A device for measuring the circumferential liquid film thickness of gas-liquid two-phase flow based on ultrasonic

A gas-liquid two-phase flow, ultrasonic measurement technology, applied in measurement devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of difficult adjustment of fit, mutual influence of transducers, and influence of signal strength, etc. Easy to take and install, solve difficult installation, improve the effect of installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

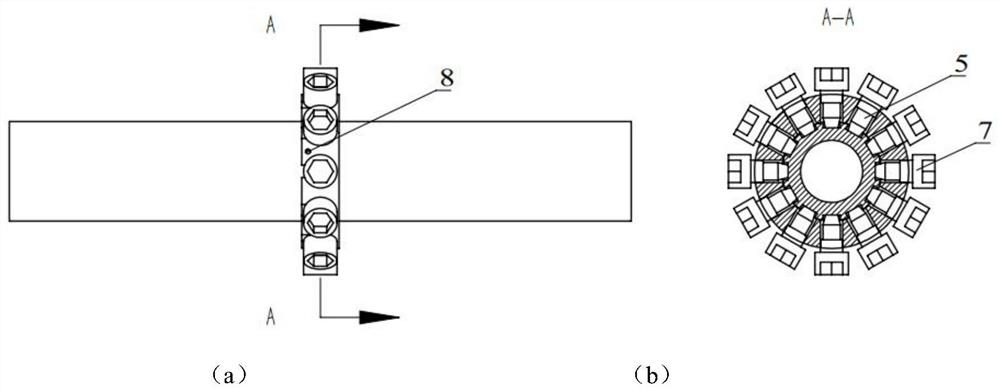

[0018] see figure 1 with figure 2 The device for measuring the circumferential liquid film thickness of gas-liquid two-phase flow based on ultrasound provided by the present invention adopts a plexiglass transparent pipe window 1 with a length of 500mm, an inner diameter of 50mm, and a thickness of 15mm, also known as a measuring pipe, to facilitate the flow in the experiment. type of observation and recording. In order to fix the installation positions of the 12 transducers, 12 holes are evenly opened in the peripheral direction of the outer wall of the plexiglass pipe window, each hole diameter is 14mm, and the depth is 5mm, which improves the installation position accuracy of the ultrasonic transducer 5. The fixed sleeve 4 is made of stainless steel. Similarly, the fixed sleeve 4 has 12 uniform openings in the circumferential direction, which run through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com