Non-excavation internal PE pipeline penetration restoration method

A technology of pipeline repair and interpenetration, which is applied in the direction of pipeline laying and maintenance, pipeline system, special pipe, etc., can solve problems such as hidden safety hazards, difficult interpenetration, and excavation of large working pits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

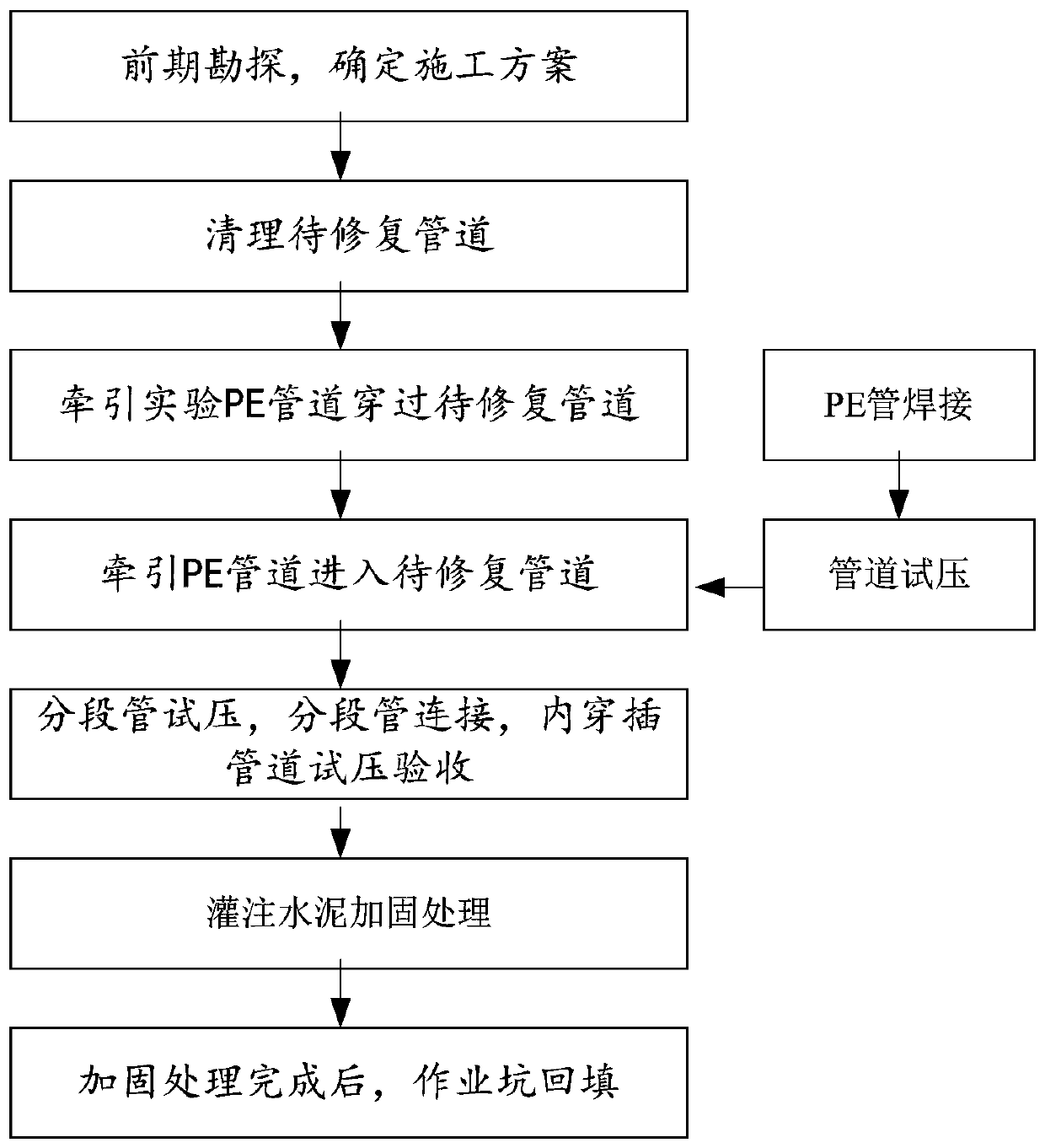

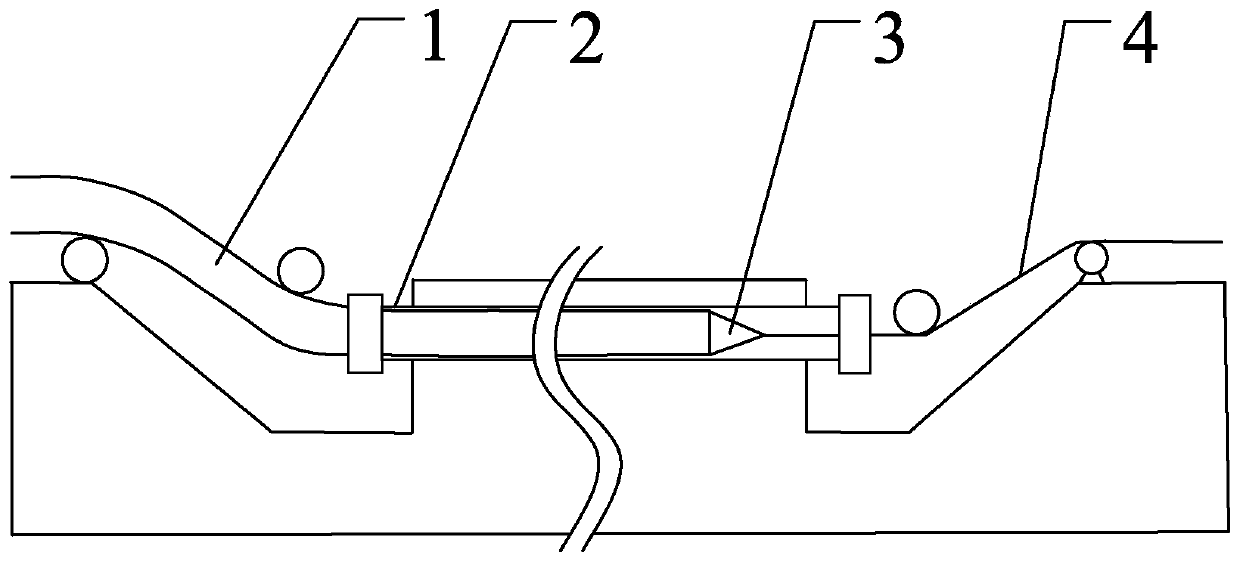

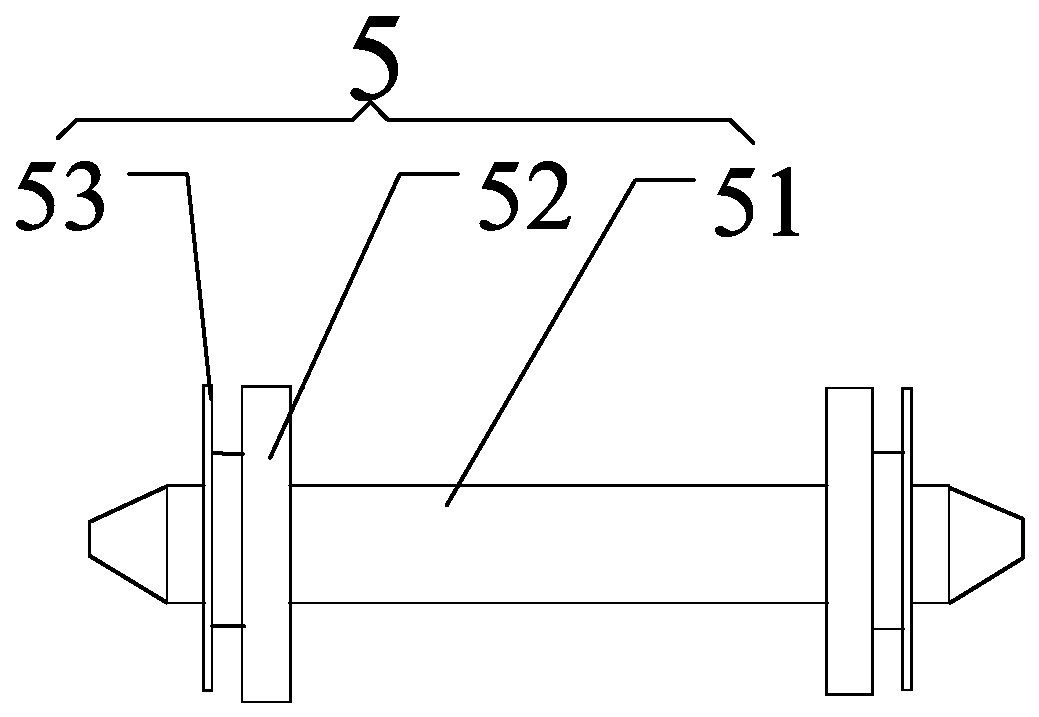

[0040] figure 1 It is a schematic flow chart of a non-excavation internally interspersed PE pipeline repair method of the present invention, figure 2 It is a schematic diagram of the structure when the present invention is interspersed, image 3 It is a structural schematic diagram of the passer of the present invention, such as Figure 1-3 As shown, a non-excavation PE pipeline repair method, the specific steps are as follows,

[0041] Step S1, pre-exploration, determine the construction length, pipe section and operation pit location.

[0042] Step S2, excavate the working pit, clean the pipeline 2 to be repaired and check whether it is qualified, and clean it again if it is not qualified, until the crossing condition is met. First, use a robot to perform an endoscopic inspection on the inside of the pipe to determine whether it is the diameter. When the pipeline 2 to be repaired is clean, the diameter of the diameter device is not needed. When the pipe is dirty (such as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com