Reciprocating piston type internal combustion engine

A technology of reciprocating pistons and internal combustion engines, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems affecting the reliability and leakage of engine pistons, and achieve the effects of low noise, easy manufacturing, and low processing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

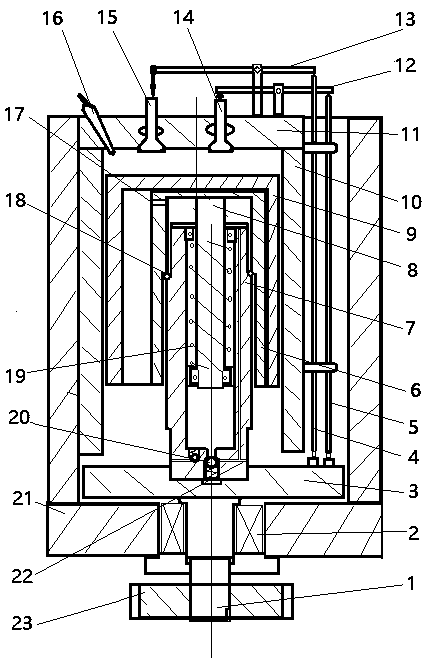

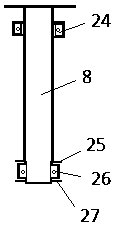

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings. Such as figure 1 , the reciprocating piston type internal combustion engine disclosed by the present invention comprises a main shaft 1, a bearing 2, a flywheel 3, an exhaust push rod 4, an intake push rod 5, an outer ring 6, an inner ring 7, a mandrel 8, a piston 9, a cylinder 10, Cylinder head 11, intake lever 12, exhaust lever 13, intake valve 14, exhaust valve 15, spark plug (fuel injector) 16, air hole 17, steel ball group 18, spring 19, one-way valve 20, body 21, Lubricating oil channel 22, power output gear 23, inner ring bearing 24, upper sealing pad 25, spindle bearing 26, lower sealing pad 27 constitute.

[0027] The raceways on the outer ring 6 and the inner ring 7 form a mechanism with two cycles and four strokes per revolution. The two push strokes are used for compression and exhaust respectively, and the two return strokes are used for combustio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com