Intelligent recycling machine for intelligent agricultural dripping pipes

A recycling machine, intelligent technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of increased burden on recycling work, increased drip pipe weight, and reduced recycling efficiency, so as to reduce the burden of handling, Effects of weight reduction and improvement of recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

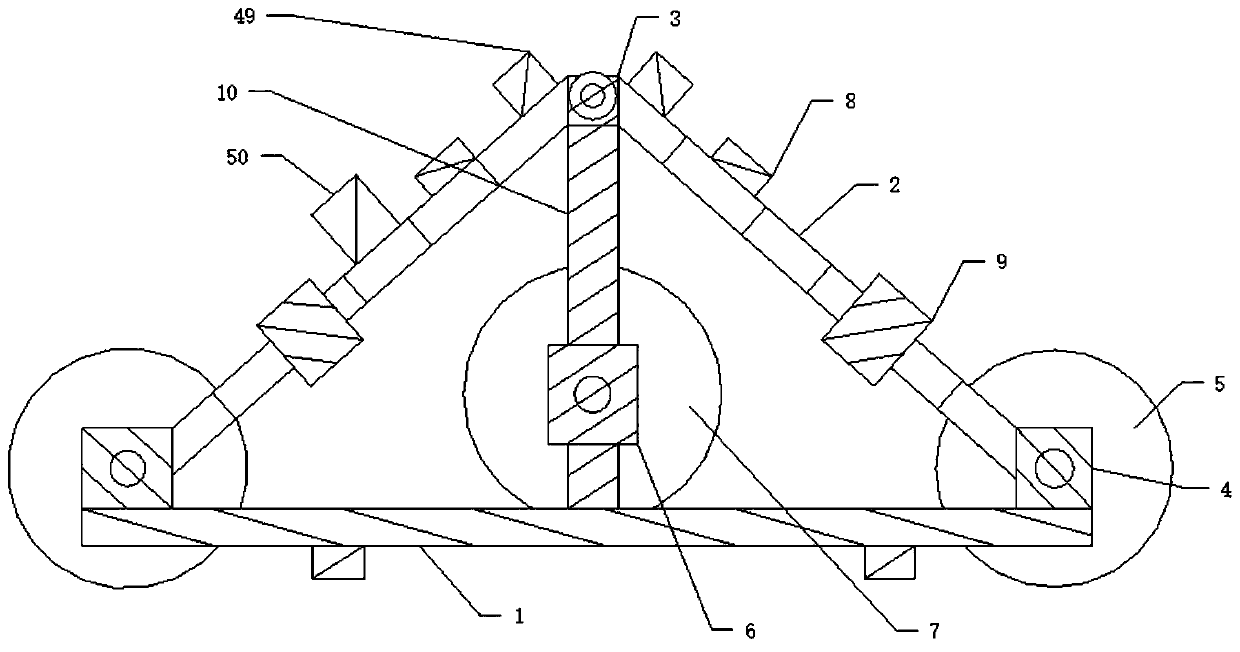

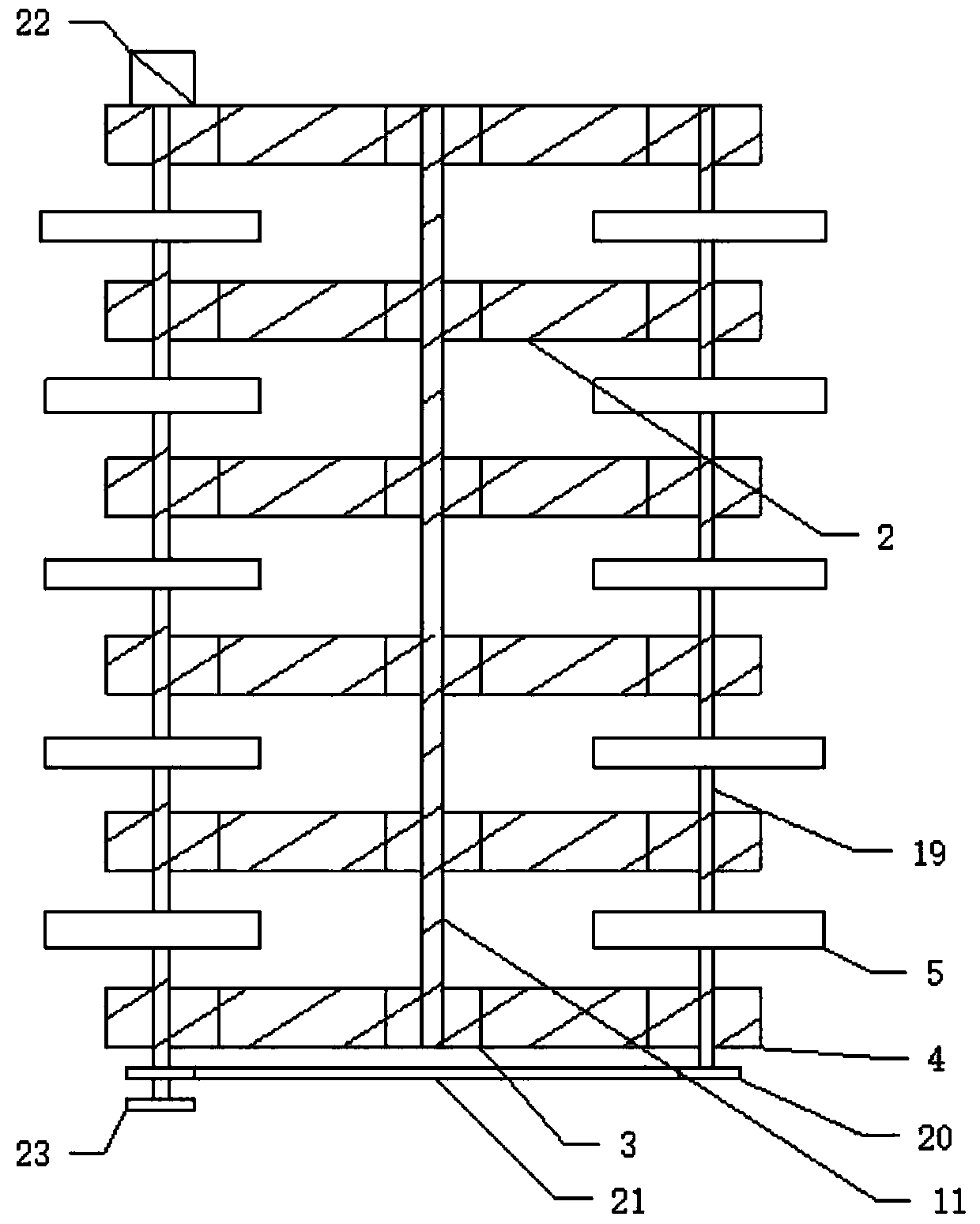

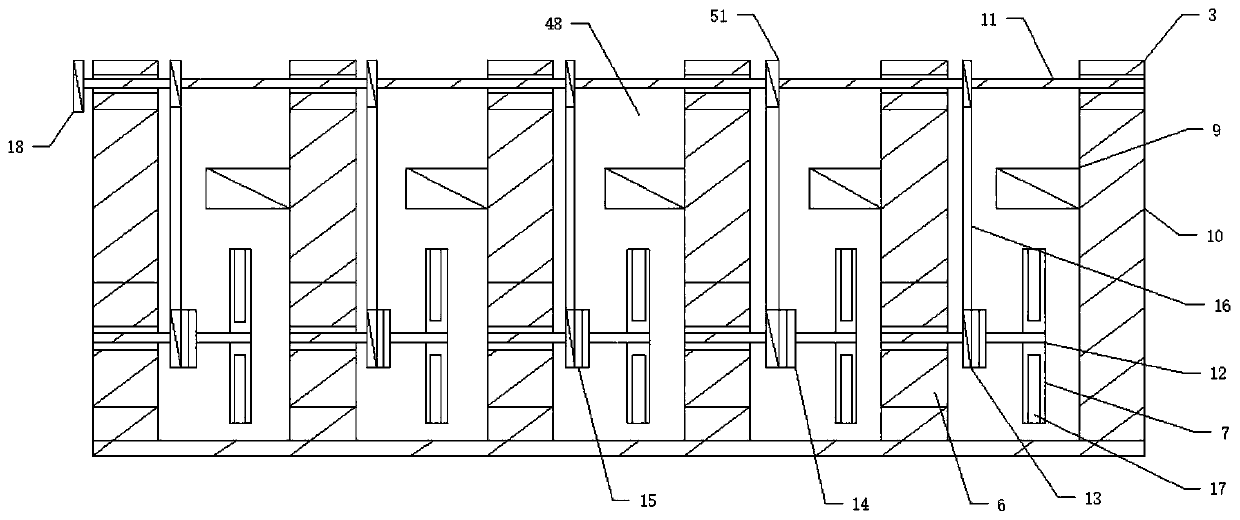

[0025] like Figure 1 to Figure 6 As shown, an intelligent agricultural dripping pipeline intelligent recovery machine includes bottom support frames 1 arranged side by side, and two ends of the bottom support frame 1 are respectively connected with a side support frame 2, and the center position of the bottom support frame 1 is A vertical support frame 10 is respectively connected, and the top of the vertical support frame 10 is respectively connected with a top connection block 3, and the side support frame 2 is respectively connected on the top connection block 3, and the bottom support The frame 1 and the side support frames 2 provided on both sides are correspondingly connected and arranged in a triangle, and the bottom support frame 1 and the side support frame 2 are connected through a support frame 8 correspondingly, and the bottom support frame The two sides of 1 are respectively connected with a bottom connecting block 4, and the bottom connecting blocks 4 arranged s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com