Leather-covered driver airbag assembly

An airbag and driver technology, which is applied in pedestrian/occupant safety arrangement, vehicle safety arrangement, transportation and packaging, etc., to achieve the effect of improving the sense of grade, good pressing feel, and high-end and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

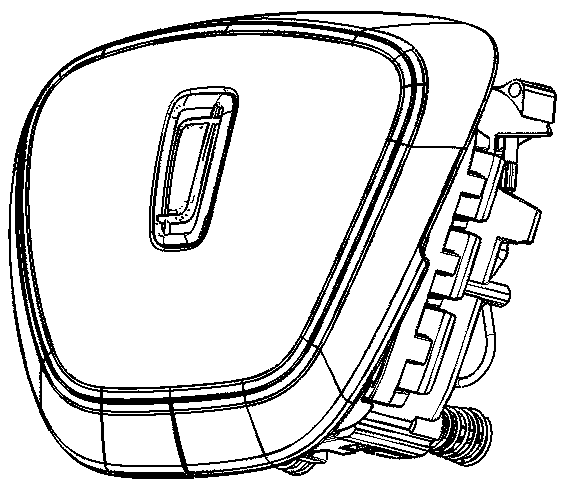

[0014] see figure 1 , figure 2 , image 3 and Figure 4 As shown, this embodiment includes an airbag body 1, an airbag cover 2, a corium layer 3 and a logo 4. The corium layer 3 is pasted on the surface of the airbag cover 2 by special glue, and the logo 4 is fixed on the leather covering by a hot-melt welding process. On the rear airbag cover 2, the airbag cover 2 is fixed on the airbag body 1 through a clamping structure. In order to ensure the smooth detonation of the airbag, the airbag cover 2 and the dermis 3 are respectively provided with a weakening line 6 structure and a weakening line 5 structure. .

[0015] Manufacturing method of the present invention comprises the steps:

[0016] 1. The airbag cover 2 with weakening line is manufactured through injection molding process. The depth of weakening line 6 on the airbag cover 2 is 0.4mm-0.7mm, and the layout is "H" shape, which is conducive to the smooth tearing of the cover when the airbag detonates ; There is a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com