Heat shrinkage pipe wrapping machine

A heat-shrinkable tube and rack technology, applied in the field of automation equipment, can solve the problems of uneven quality of protective layer, low production efficiency and high labor cost, and achieve the effects of improving market competitiveness, improving work efficiency and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

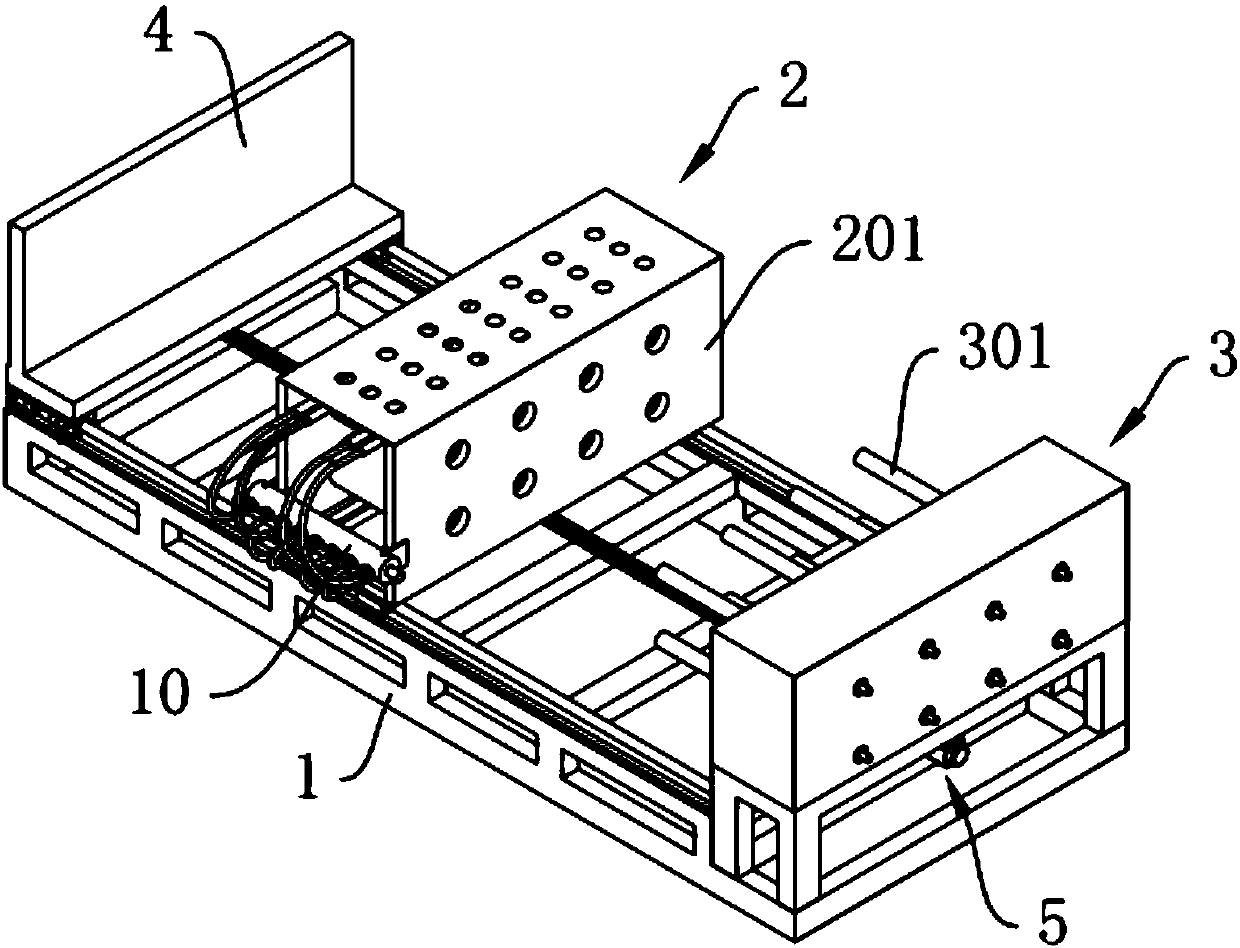

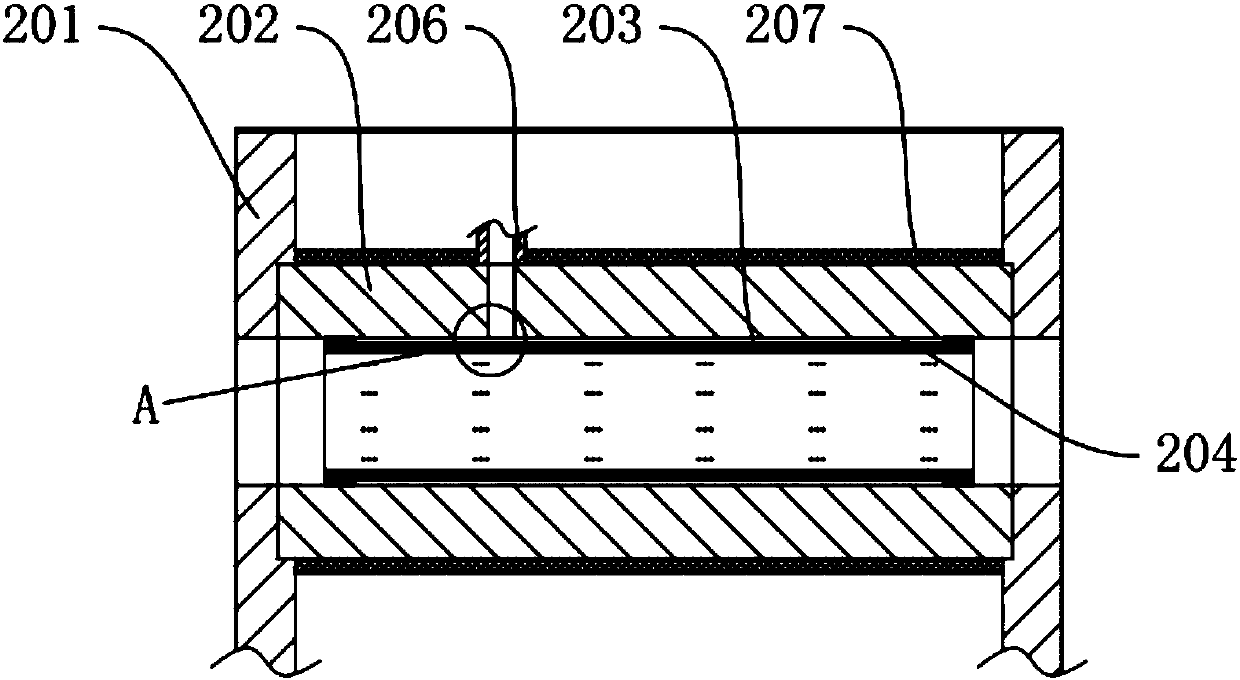

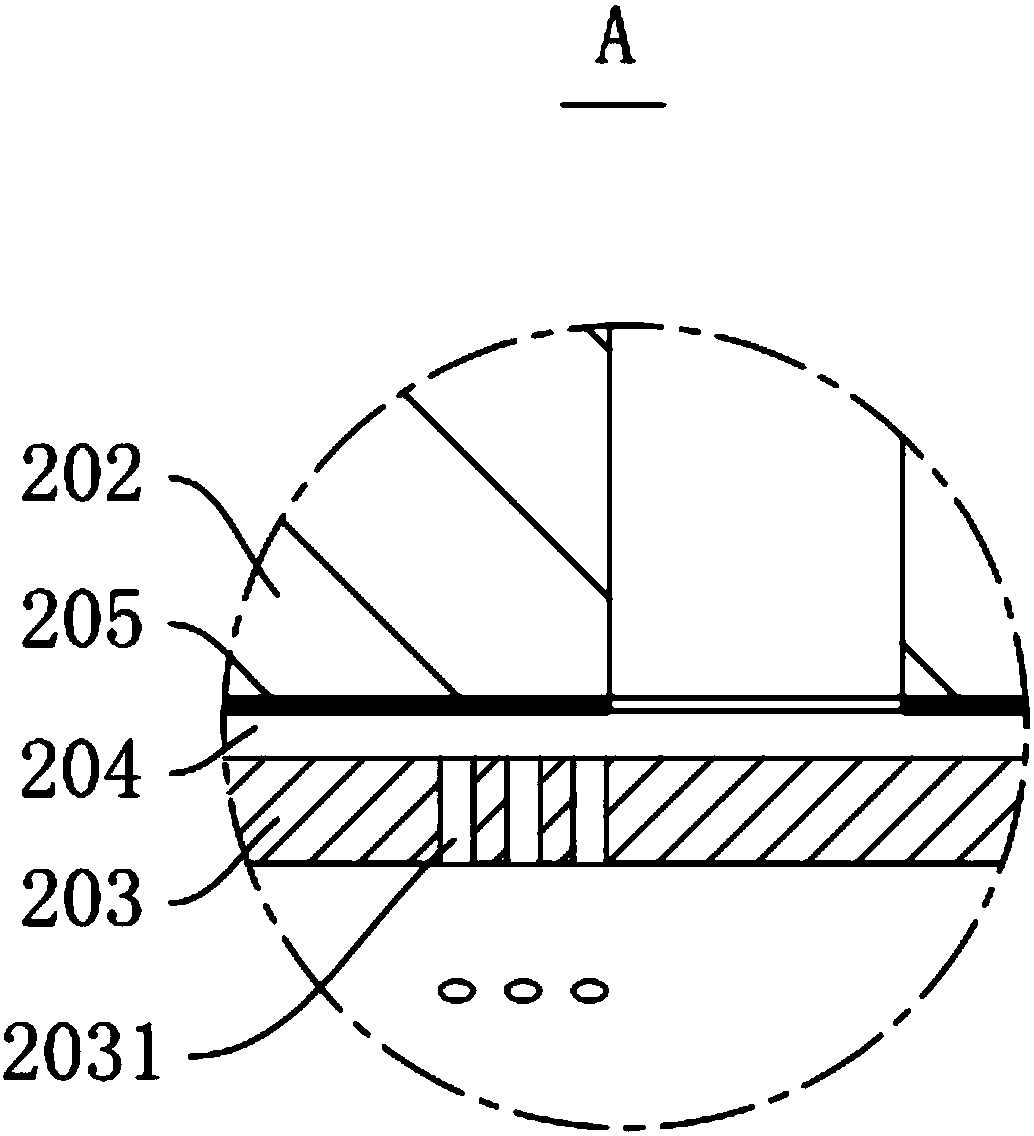

[0036] see figure 1 , a heat-shrinkable tubing machine, comprising a frame 1, a heating device 2 is slidably connected to the frame 1, combined with figure 2 and 3 , the heating device 2 includes a heating rack 201, and 8 heating cylinder assemblies are arranged in an array in the heating rack 201. The heating cylinder assembly includes a heating cylinder 202 fixedly installed on the heating rack 201, and a heat conducting cylinder 203 is pierced in the heating cylinder 202, and the heat conducting cylinder 203 is made of high thermal conductivity material. In this embodiment, the heat conduction cylinder 203 is made of copper. There is a ring groove on the outer wall of the middle part of the heat conduction cylinder 203. A heating chamber 204 is formed between the heat conduction cylinder 202 and the heat conduction cylinder 203. In the heat conduction cylinder 202 An electric heater 205 is attached to the inner wall of the heating chamber 204. The electric heater 205 is s...

Embodiment 2

[0042] see Figure 5 , a heat-shrinkable tubing machine. The difference between this embodiment and Embodiment 1 is that the fixed rod 301 is rotatably connected to the fixed frame 302, and the fixed frame 302 is fixed with a rotating motor 303 inside. The connection between the rotating motor 303 and the fixed rod 301 The connection between them is driven by a sprocket 304 and a chain 305. The fixed rod 301 adopts an air expansion shaft, and the air inlet end of the fixed rod 301 is connected with an air compressor. The thermal insulation layer 207 provided on the outer wall of the heating cylinder 202 is formed by uniform coating of thermal insulation paint, specifically adopting model ZS-211 reflective thermal insulation paint.

[0043] In actual operation, after the pipe covered with the heat-shrinkable tube to be heated is placed on the fixed rod 301, the fixed rod 301 can completely fix the pipe after being ventilated. When the heat-shrinkable tube is heated in the heati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com