Inverted hook formation structure and formation method of product

A technology for forming structures and products, applied in the direction of coating, etc., can solve the problems of normal demoulding, products can not be demolded normally, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

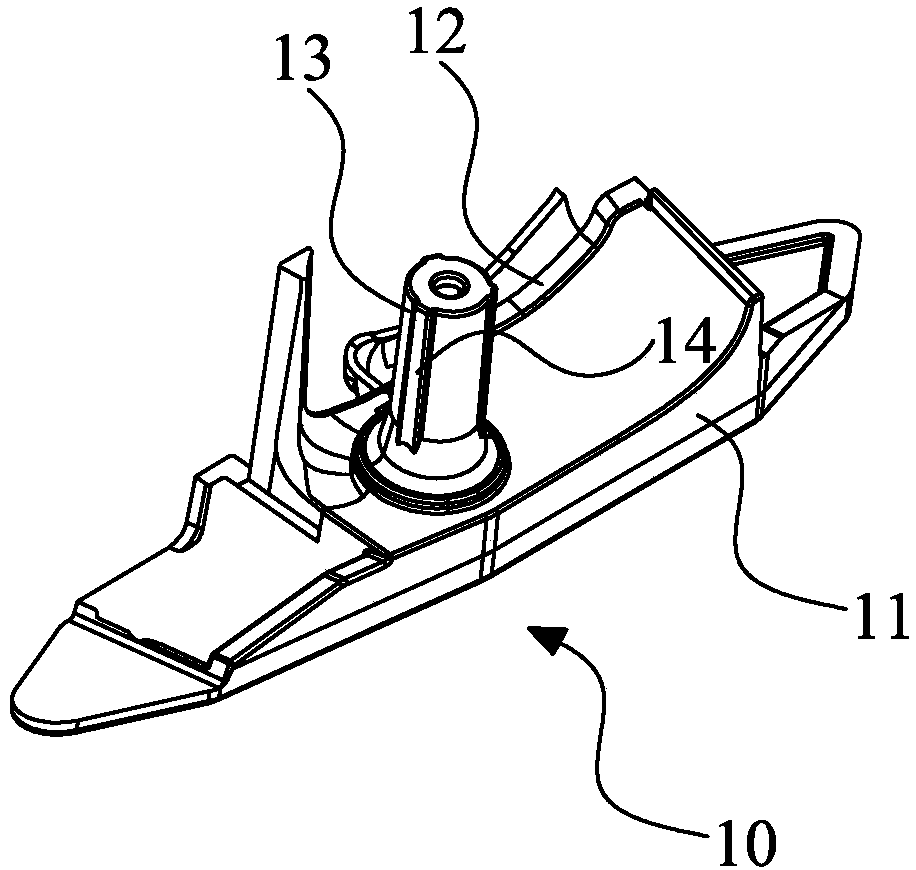

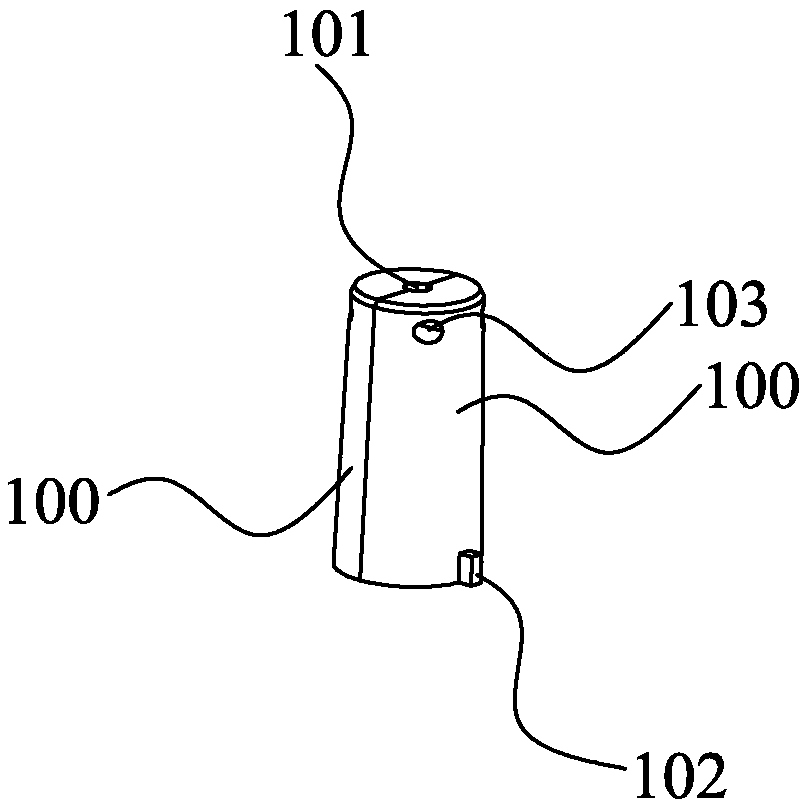

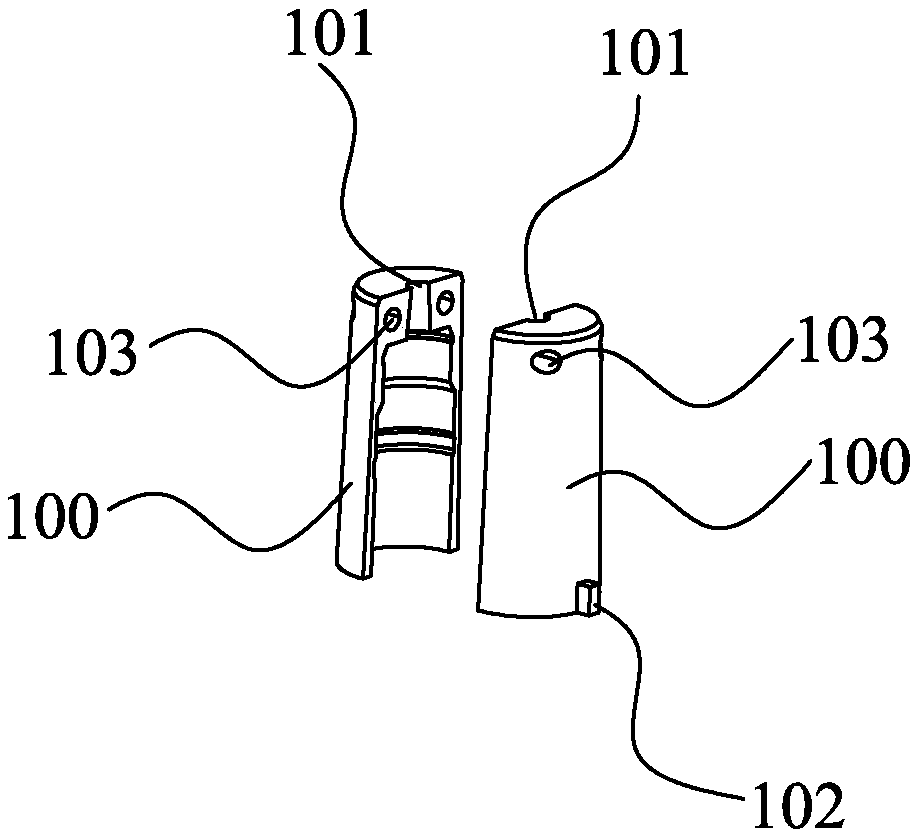

[0030] see Figure 2 to Figure 5 shown, where figure 2 A schematic diagram showing the undercut molding structure of the product of the present invention, image 3 An exploded schematic view of the undercut molding structure of the product of the present invention is shown, Figure 4 A schematic diagram showing the forming of the undercut forming structure of the product of the present invention, Figure 5 A schematic diagram of the undercut forming structure of the product of the present invention in the mold is shown.

[0031] In a preferred embodiment, the undercut forming structure of the product of the present invention is applied in a mold, and the product 10 can be a part of an automobile, and the product 10 is a combination of a metal part 11 and a plastic part 12, so The plastic part 12 has a cylindrical structure 13, the outer ring of the cylindrical structure 13 is provided with a barb 14, and the barb forming structure of the product includes:

[0032] Two ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com