Automatic tolerance adjusting device

An automatic adjustment device and tolerance technology, applied in hand-held tools, manufacturing tools, etc., can solve the problems of high cost, low work efficiency, and many processes, and achieve the effect of increasing friction and preventing position deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

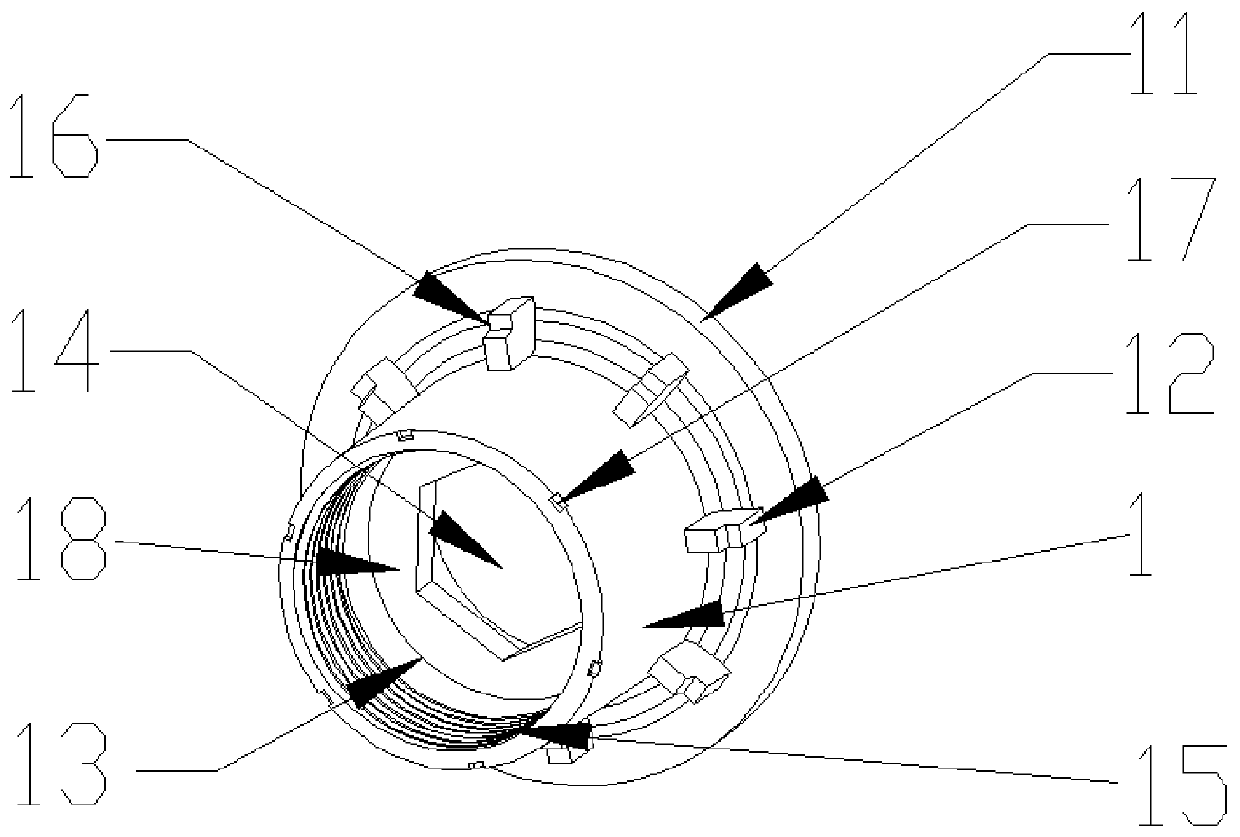

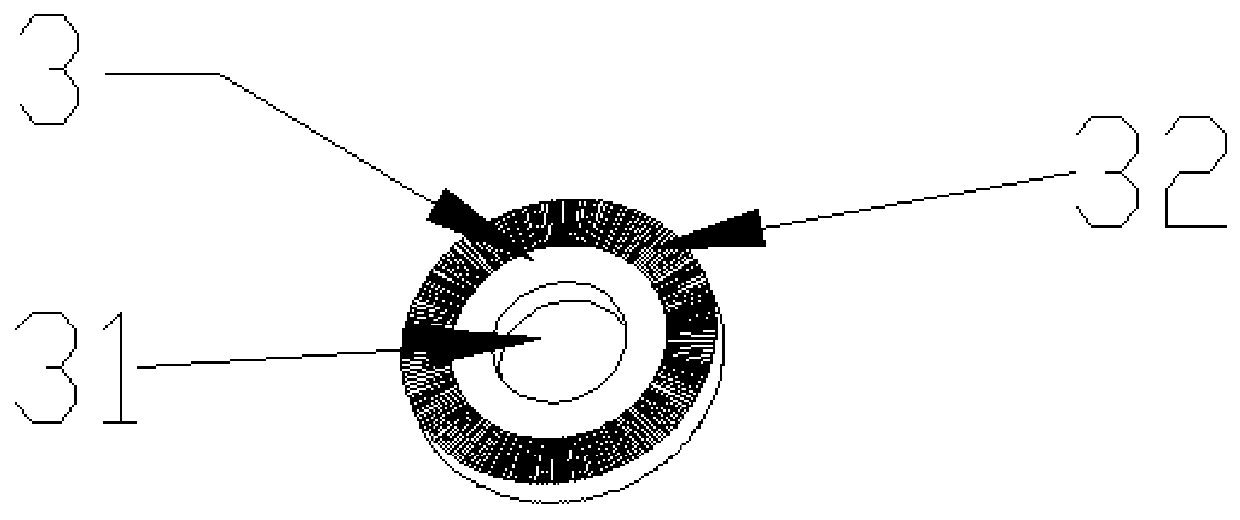

[0040] This embodiment provides a tolerance automatic adjustment device, its structure is detailed in the attached Figure 1-4 As shown: it includes an upper case 1, a positioning stud 2, a locking washer 3 and an elastic adjustment piece 4; the upper case 1 is a hollow cavity structure, and its inner cavity is divided into a mounting hole 14 and a first The inner cavity 13, the opening end of the installation hole 14 is provided with a raised outer edge 11, and the outer wall of the upper shell 1 is provided with a positioning rib 12; the elastic adjusting piece 4 is arranged on the outer surface of the positioning rib 12; The middle part of the positioning stud 2 is provided with a boss 26 that matches the first inner cavity 13, and the boss 26 is inserted into the first inner cavity 13, and the upper shell 1 and the positioning stud 2 are fixed through threaded connection; The locking washer 3 is arranged in the first inner chamber 13 and moves freely in the shaft hole gap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com