Automatic sectional material cutting production equipment and method

A technology for automatic cutting and production equipment, applied in workshop equipment, welding equipment, metal processing equipment, etc., can solve the problems of high maintenance and processing costs, poor quality, and difficult processing of complex wedge-head workpieces, etc., to reduce labor intensity and transport And the effect of reasonable connection and clear and orderly rhythm of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

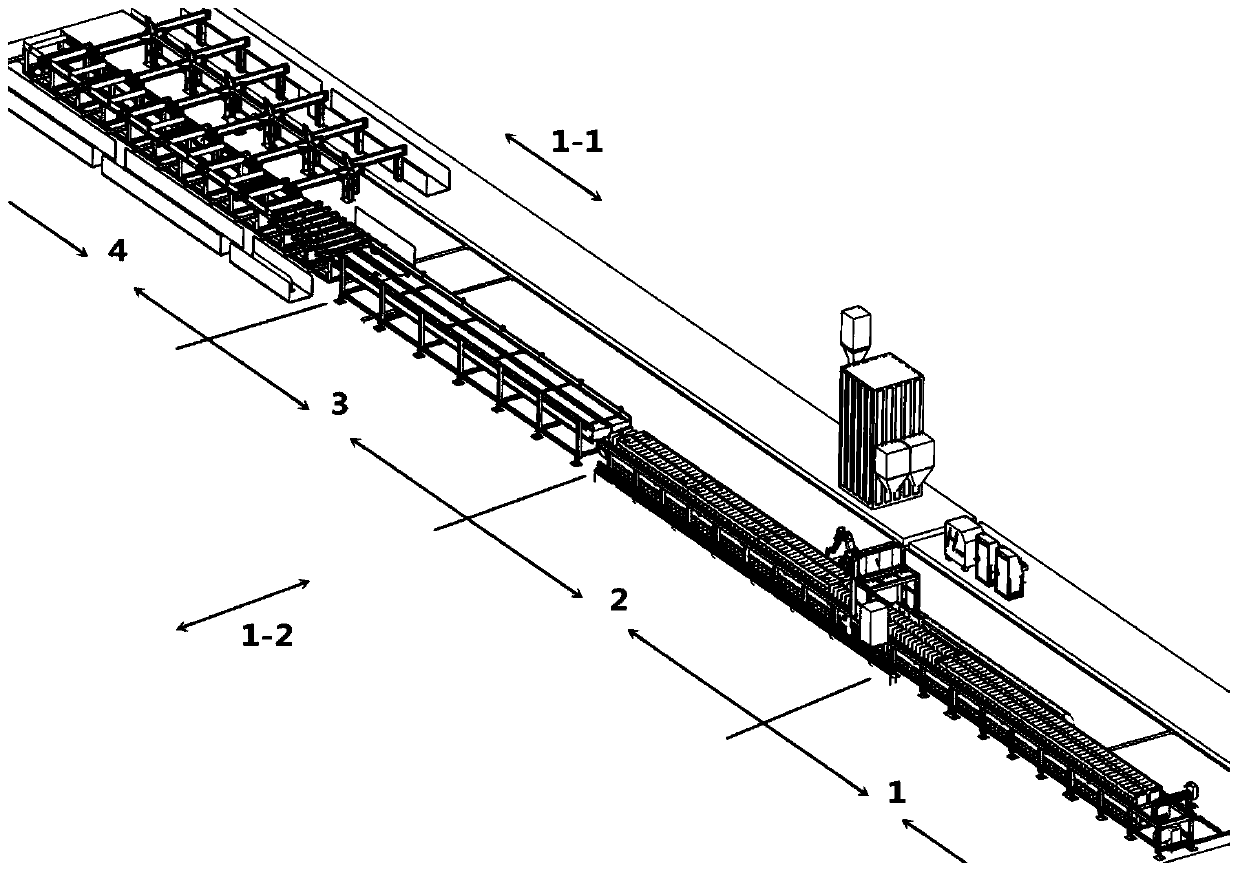

[0058] Such as figure 1 As shown, an automatic profile cutting production equipment adopts a rotary chain plate to transfer workpieces. The layout of the main functional work area includes: X-axis vertical 1-1, Y-axis horizontal 1-2, material spraying area 1, cutting area 2 , to be sorted area 3 and unloading area 4.

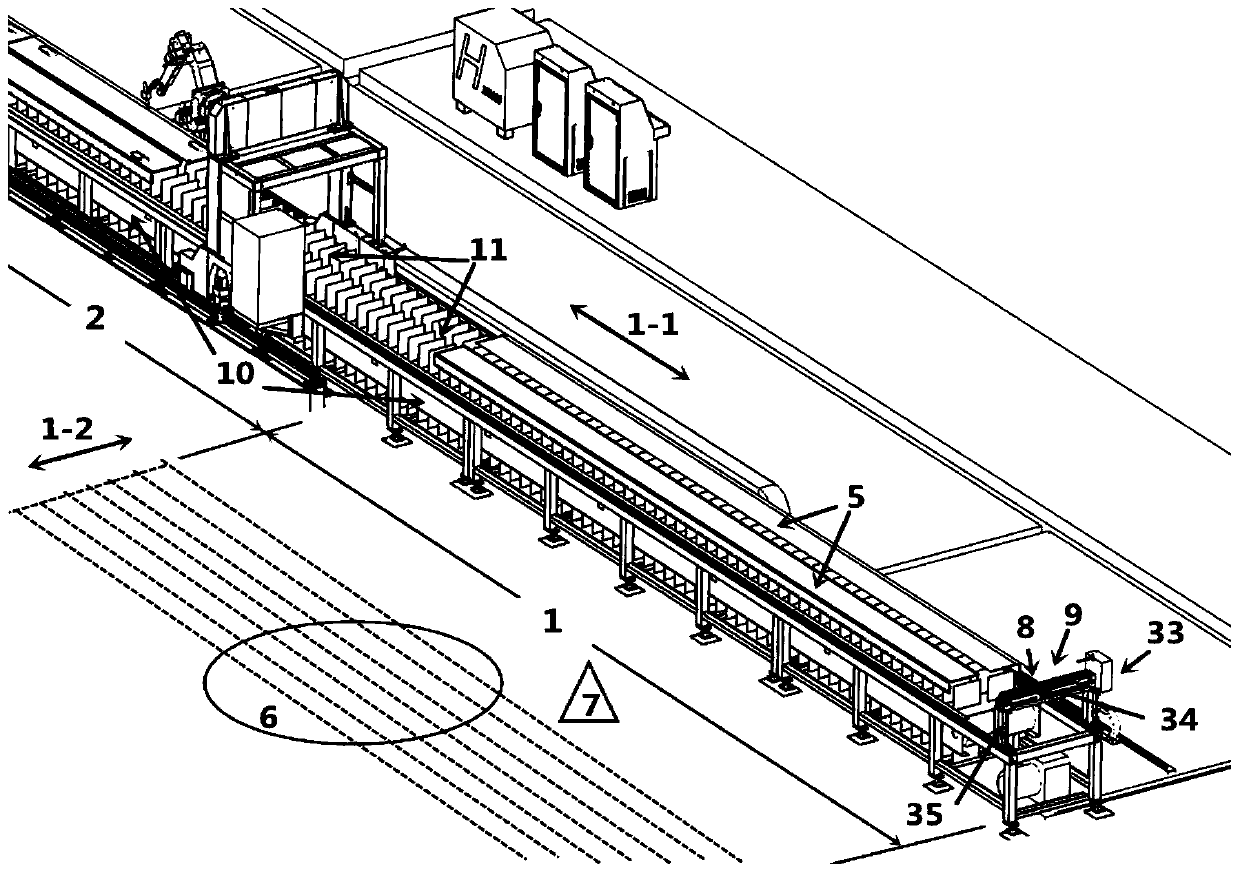

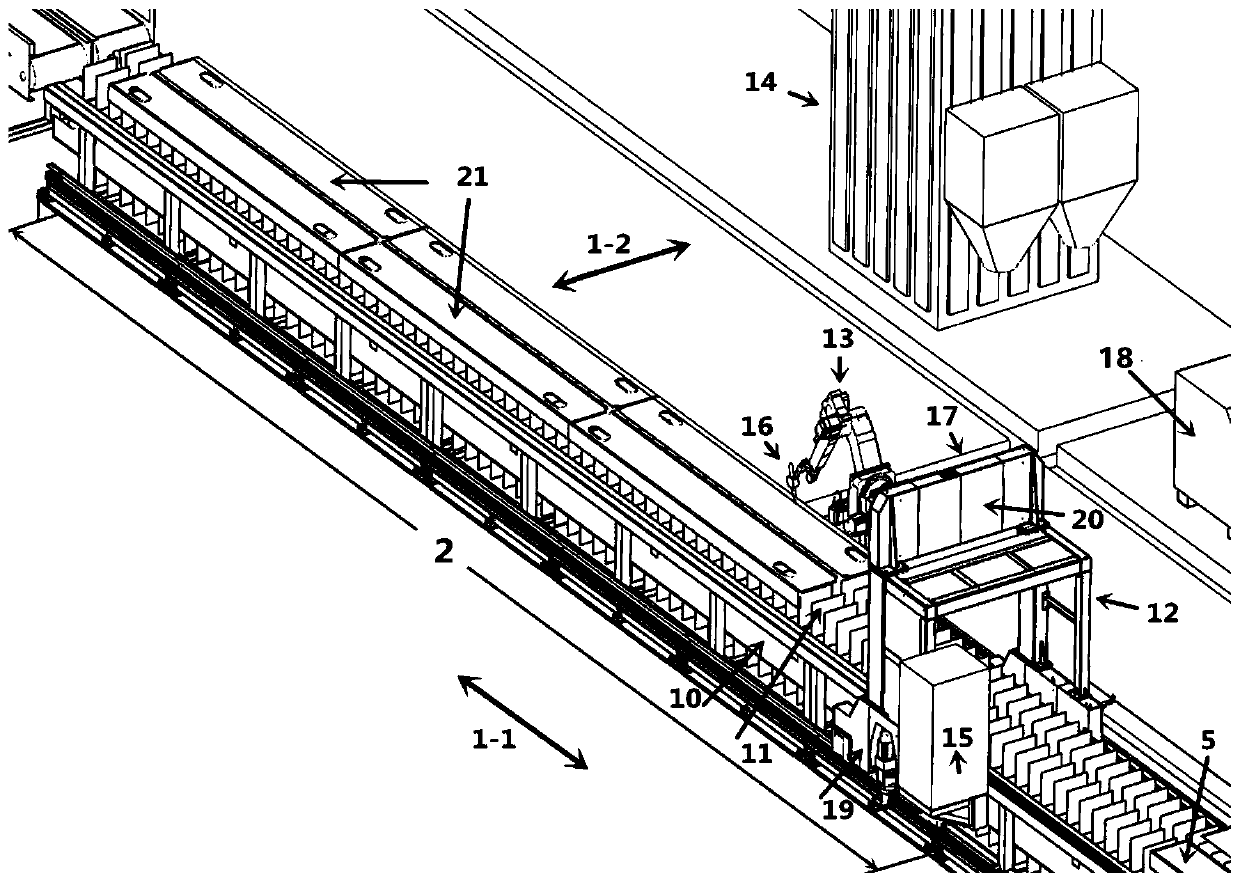

[0059] Such as figure 2 , 3 As shown, the feeding coding area 1 and the cutting area 2 jointly use a set of rotary chain plate transmission mechanism 10 and two sets of parallel material tables 11 to complete the transmission, coding, scribing and cutting of two sets of profile raw materials 5 .

[0060] Such as Figure 4 As shown, the area to be sorted 3 has adopted two sets of second rotary chain plate transmission mechanisms 22 arranged in parallel, and a waste collection vehicle 23 arranged at the lower end of the gap between the area to be sorted 3 and the cutting area 2, and the area to be sorted The sorting area 3 is mainly responsible for completing...

Embodiment 2

[0080] A profile automatic cutting method, using the above profile automatic cutting production equipment, comprising the following steps:

[0081]S1. Place the two profile raw materials 5 from the profile buffer storage area 6 to the two sets of parallel material tables 11 in the loading and coding area 1 through the combined electro-permanent magnet spreader 7, start the laser measurement and control and coding and scribing procedures, and install The coding and scribing device 8 and the laser measurement and control device 9 on the plotter 33 automatically complete the deformation measurement and control and coding and scribing operations of two groups of profile materials;

[0082] S2. Start the automatic cutting program, the first rotary chain plate workpiece transmission mechanism 10 transfers the two groups of profile materials 5 that have completed the coding and scribing operation to the cutting area 2, and the cutting robot body 13 cuts the profile materials 5 to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com