Powder cosmetics forming method

A molding method and cosmetic technology, applied in material molding presses, heating devices, dryers, etc., can solve the problems of dust formation, consumption of steel and aluminum materials, and impact on the health of production workers, so as to save production costs and reduce The effect of energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

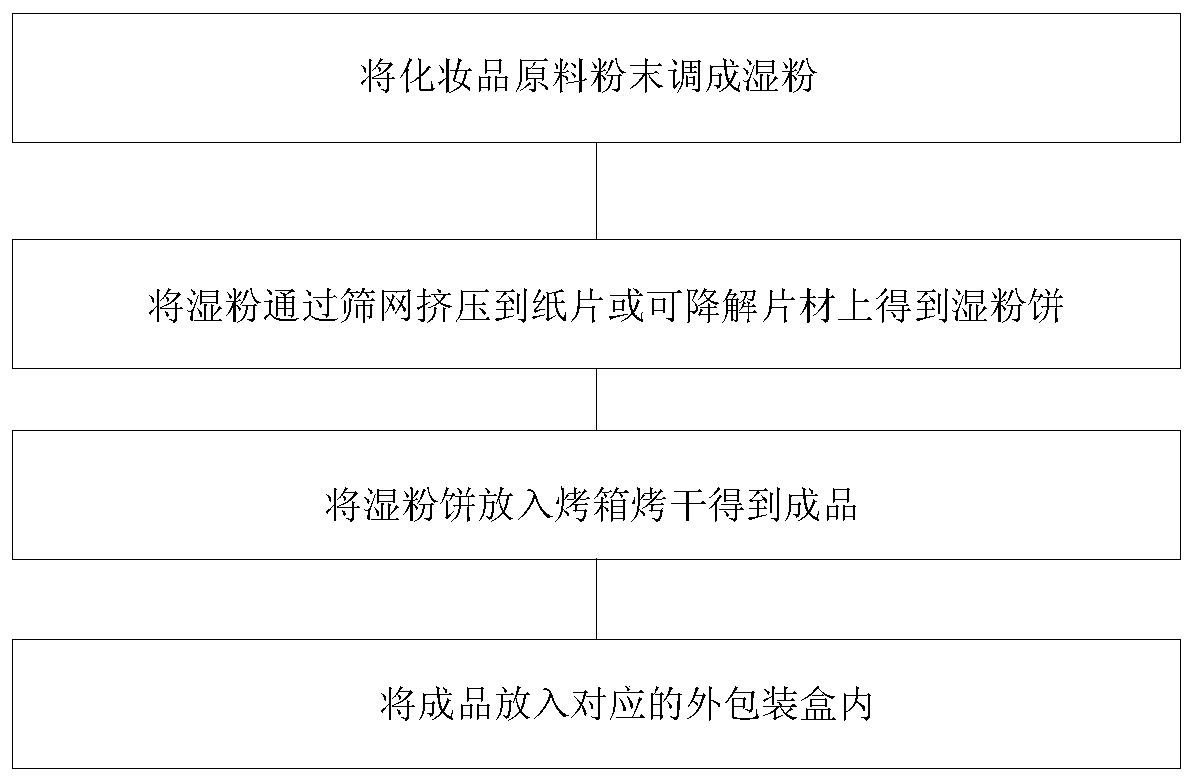

[0017] This embodiment provides a molding method for powder cosmetics, comprising the following steps:

[0018] S1. Add a diluent to the cosmetic raw material powder to make a wet powder; the diluent can be HGC-S01 diluent;

[0019] S2. Extrude the wet powder through a screen onto a paper sheet or a degradable sheet to obtain a wet powder cake; the screen has one or more forming spaces, and the shape of the forming space is consistent with the preset product shape ;

[0020] S3. Put the paper sheet or degradable sheet together with the wet powder into an oven at a temperature of 50-80°C to evaporate and dry the liquid to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com