Greenhouse cascaded heat storage water tank

A heat storage tank and connected row technology, applied in the field of greenhouses, can solve problems such as single production process, small heat storage, and low heat conversion efficiency, and achieve the effects of increasing greenhouse temperature, prolonging service life, and high heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The core of the present invention is to provide a greenhouse connected heat storage tank to optimize various performances of the heat storage tank.

[0035] In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solutions of the invention described in the claims.

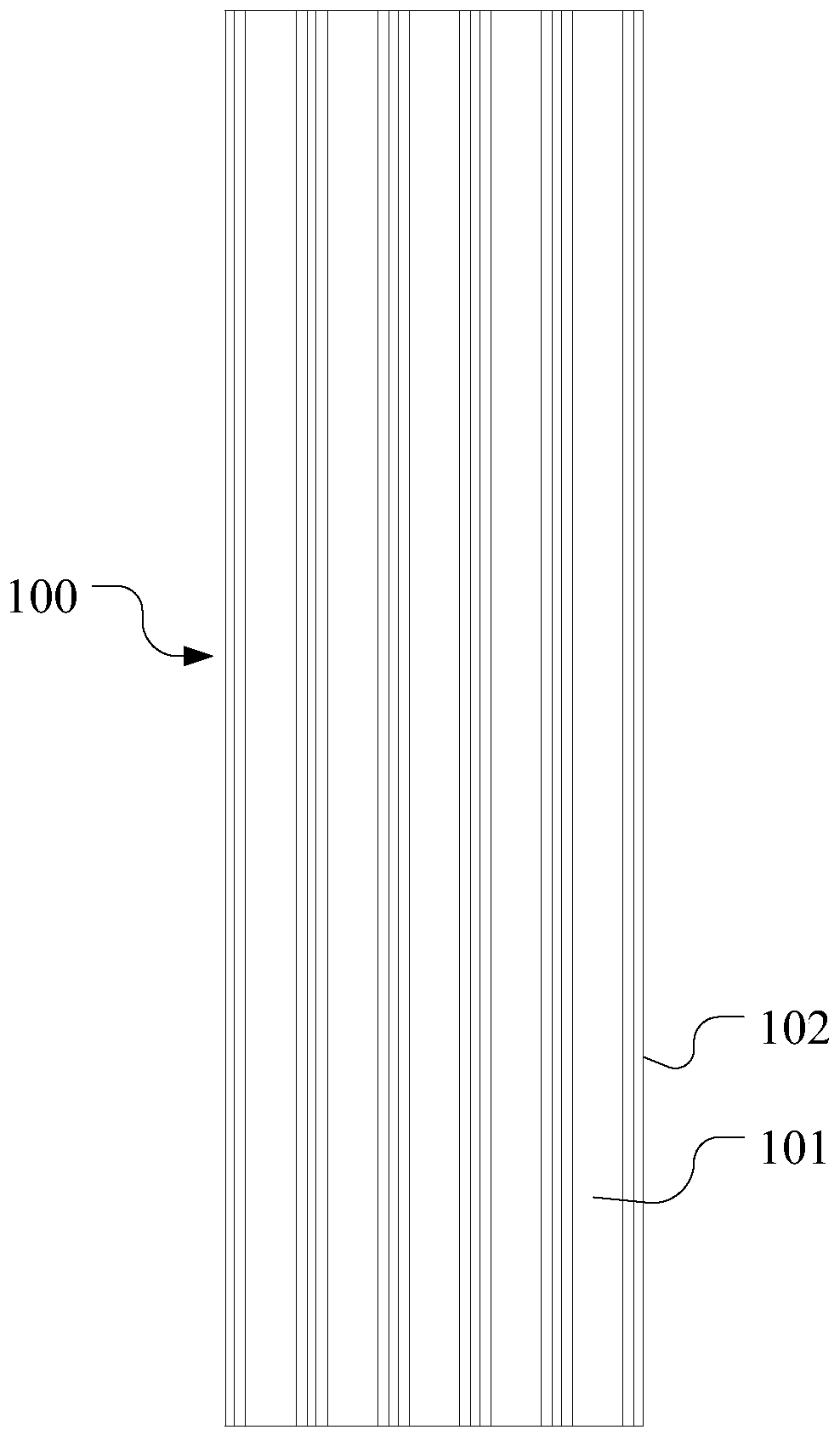

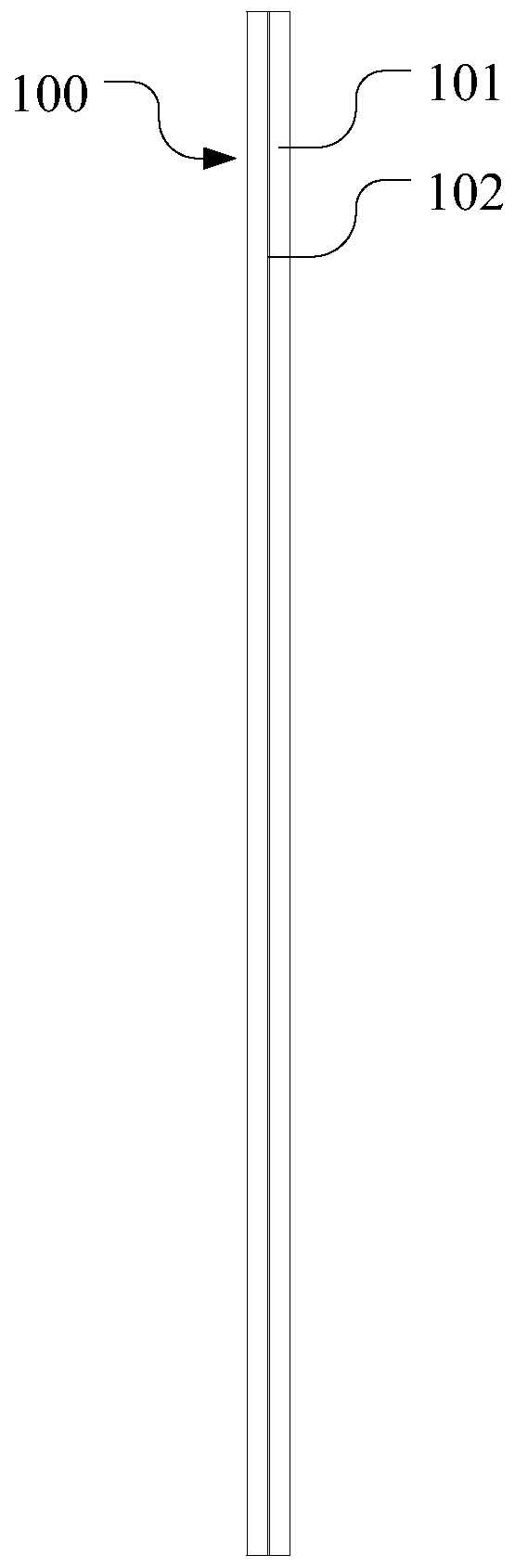

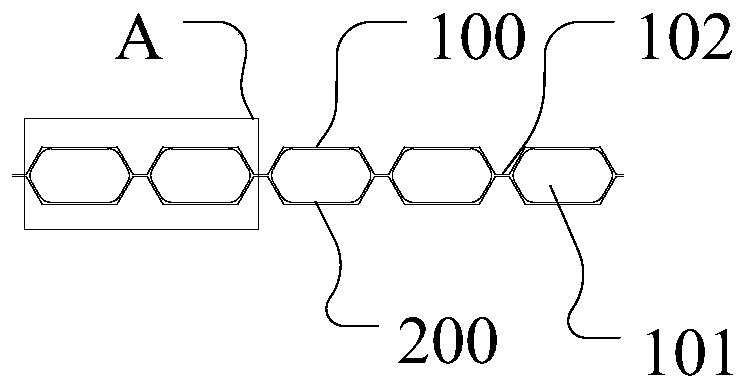

[0036] see Figure 1 to Figure 16 , the greenhouse connected heat storage tank in the embodiment of the present invention includes a water tank shell 100 and a plastic film sleeve 200, wherein the water tank shell 100 is composed of a plurality of columnar cavities 101 in a row, and each columnar cavity 101 There is a plastic film sleeve 200 correspondingly.

[0037] The heat storage tank of the present invention separates the design of the strength-bearing structure and the leak-proof structure, that is, the water tank she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com