Permanent magnet synchronous motor rotor with high-performance tangential magnetic circuit structure

A permanent magnet synchronous motor, high-performance technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, magnetic circuit, etc., can solve problems such as poor structural strength, easy demagnetization, and no magnetic gathering ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

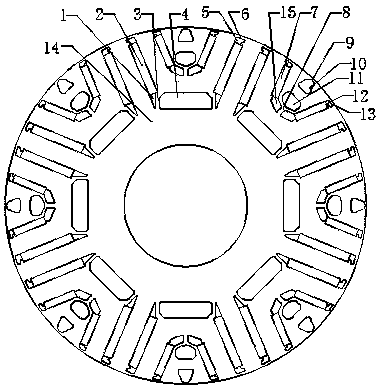

[0021] Such as figure 1 Shown, the permanent magnet synchronous motor rotor of the high-performance tangential magnetic circuit structure of the present invention, it comprises rotor iron core 14, first magnetic steel 2 and second magnetic steel 7, rotor iron core 14, first magnetic steel 2 and The second magnetic steel 7 forms several magnetic poles, which are distributed alternately.

[0022] The first magnetic steel 2 and the second magnetic steel 7 are respectively embedded in the interior of the rotor core 14, and each magnetic pole of the rotor is composed of two first magnetic steels 2 and two second magnetic steels 7, which are evenly and symmetrically distributed in the center of the magnetic poles On both sides of the line, the first magnetic pole 2 is outside the second magnetic pole 7 .

[0023] In this embodiment, the angle between the first magnets 2 is 360 degrees divided by the number of poles, and the angle between the second magnets 7 is 360 degrees divided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com