Seedling separating mechanism, method of seedling separating mechanism and pot seedling transplanter

A technology of seedling separation and driving mechanism, which is applied in the field of pot seedling transplanting machines and seedling separation mechanisms, which can solve the problems of inability to adjust the planting row spacing, overweight, fixed seedling cup spacing, etc., to ensure the accuracy of seedling separation and operation Efficiency, reduction of equipment power demand, and effect of load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

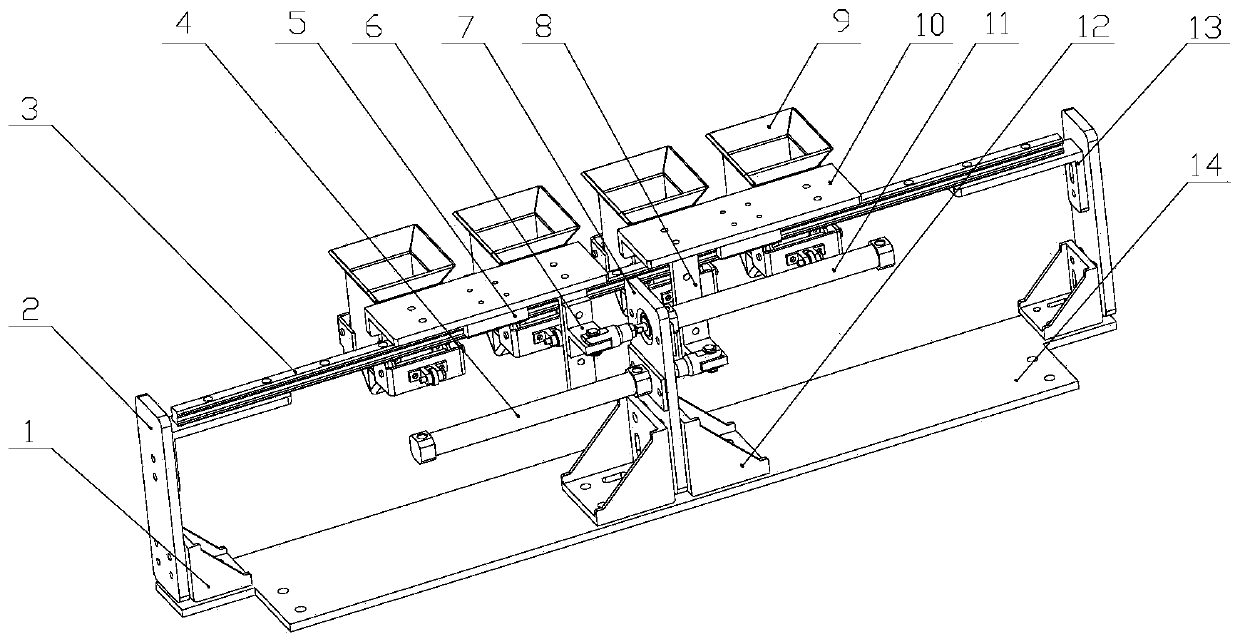

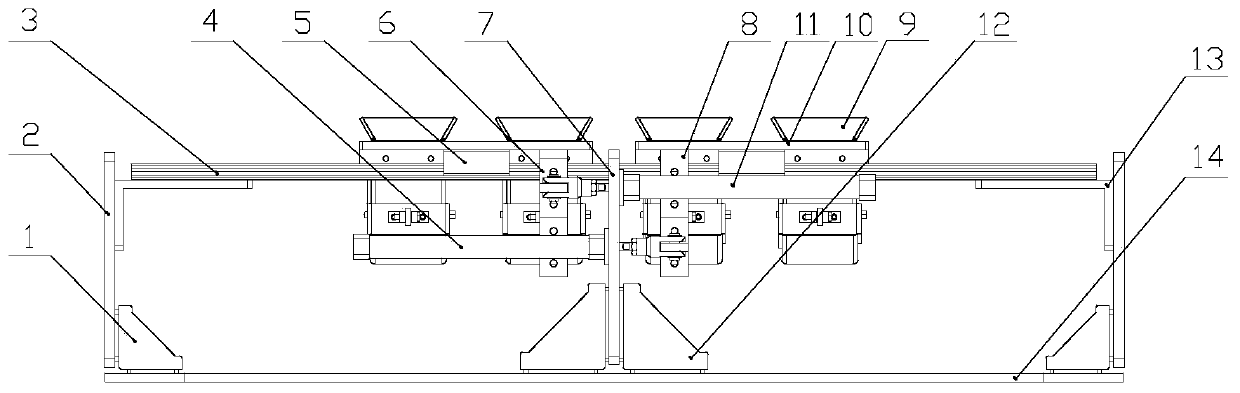

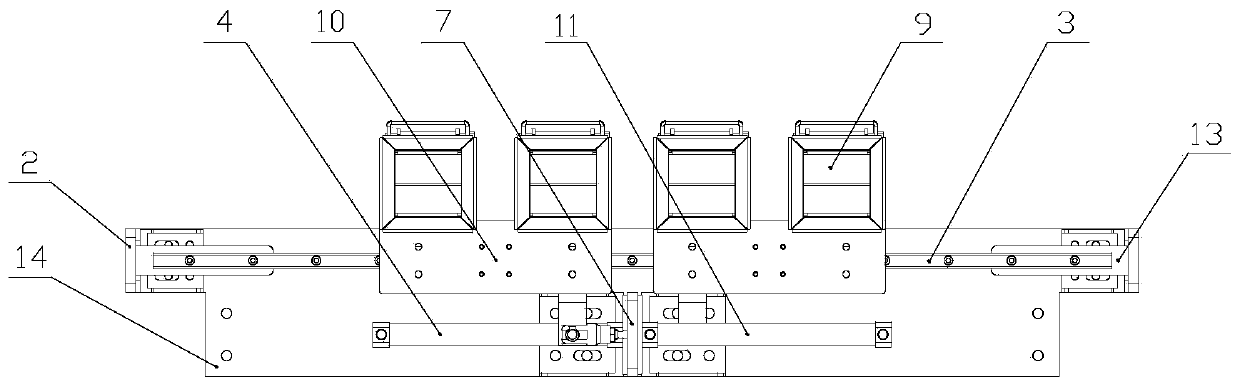

[0041] Figure 1-4 Shown is a preferred embodiment of the seedling separation mechanism of the present invention, the seedling separation mechanism includes several seedling cups 9, seedling cup linear moving devices and a control system;

[0042] Several seedling cups 9 are divided into at least two symmetrically arranged seedling cup groups;

[0043] The seedling cup linear moving device includes at least two driving mechanisms, a linear guide rail 3, a slide block 5 and at least two seedling cup mounting parts 10; the seedling cup groups are installed on the seedling cup mounting parts 10 respectively, and the seedling cups Mounting part 10 is installed on the slide block 5, and described slide block 5 is installed on the linear guide rail 3, and described drive mechanism is connected with seedling cup mounting part 10 respectively, drives seedling cup mounting part 10 to do linear motion on linear guide rail 3;

[0044] The control system is connected with the driving mec...

Embodiment 2

[0064] A pot seedling transplanting machine includes the seedling separating mechanism described in Embodiment 1, so it has all the beneficial effects of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com